You have a brilliant idea for a makeup brush line1, but the path forward seems confusing. You worry about high costs and finding a factory that takes your vision seriously. I’m here to show you the exact steps to launch your brand successfully.

To start a makeup brush line, first choose between ODM for a fast launch or OEM2 for a unique product. Then, engineer your brushes with high-performance synthetic fibers and sustainable handles. Finally, plan your costs, timeline, and compliance needs for a smooth import process.

The global market for makeup tools is growing fast. It’s expected to be worth between $3.7 billion and $7.0 billion in 2024. This is a great time to build your brand. When I first started on the factory floor, I saw so many entrepreneurs struggle with the first few steps. They didn’t know where to begin. That’s why I want to share what I’ve learned from helping hundreds of brands, just like yours, get started. We will walk through the four most important decisions you need to make to bring your brush line to life.

The global makeup tools market is projected to be worth nearly $13 billion by 2034.True

Global Market Insights forecasts the market to grow from USD 7.0B in 2024 to USD 12.9B by 2034, showing strong and sustained consumer demand.

OEM vs. ODM: Which Path Gets Your Brush Line Market‑Ready Faster?

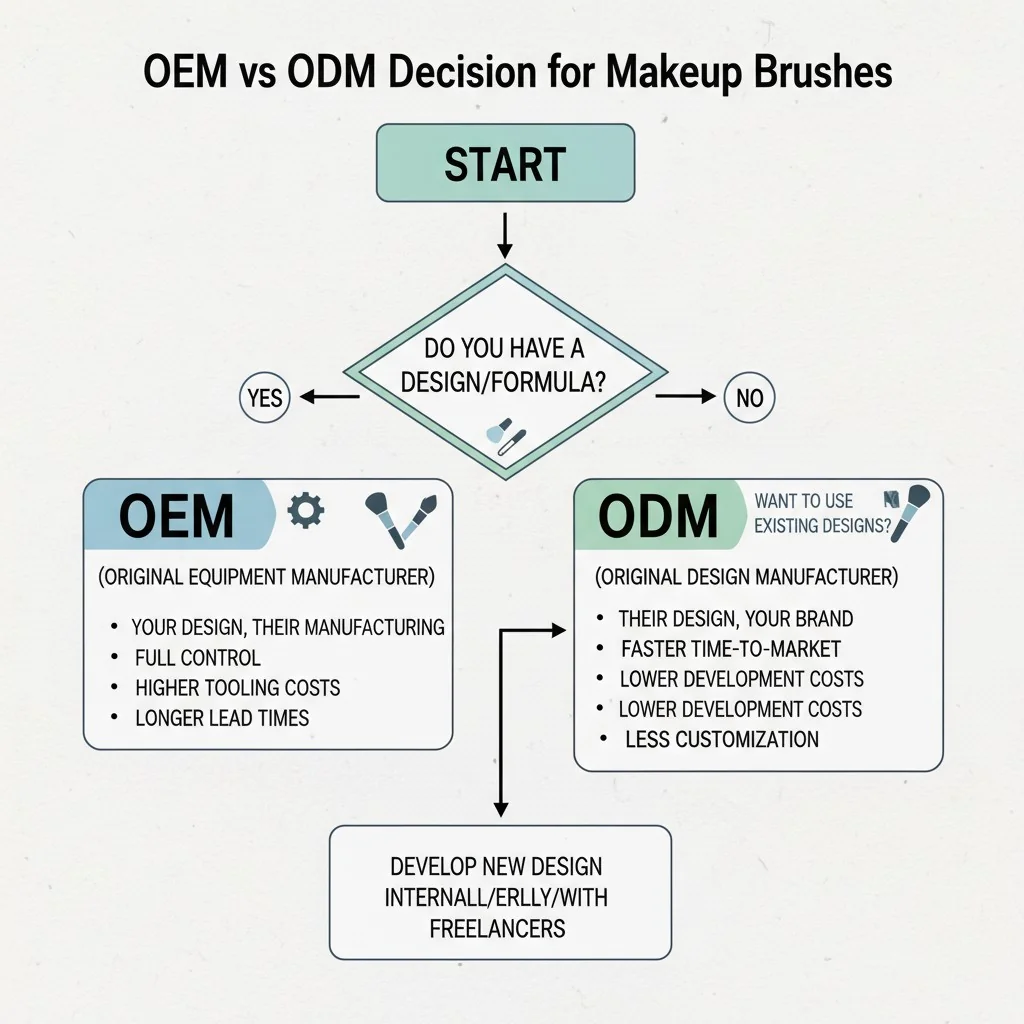

You’re ready to make your brushes, but you’re stuck on a key question. Should you use a factory’s existing designs or create your own from scratch? Making the wrong choice can waste your budget and delay your launch. Let’s find the right path for you.

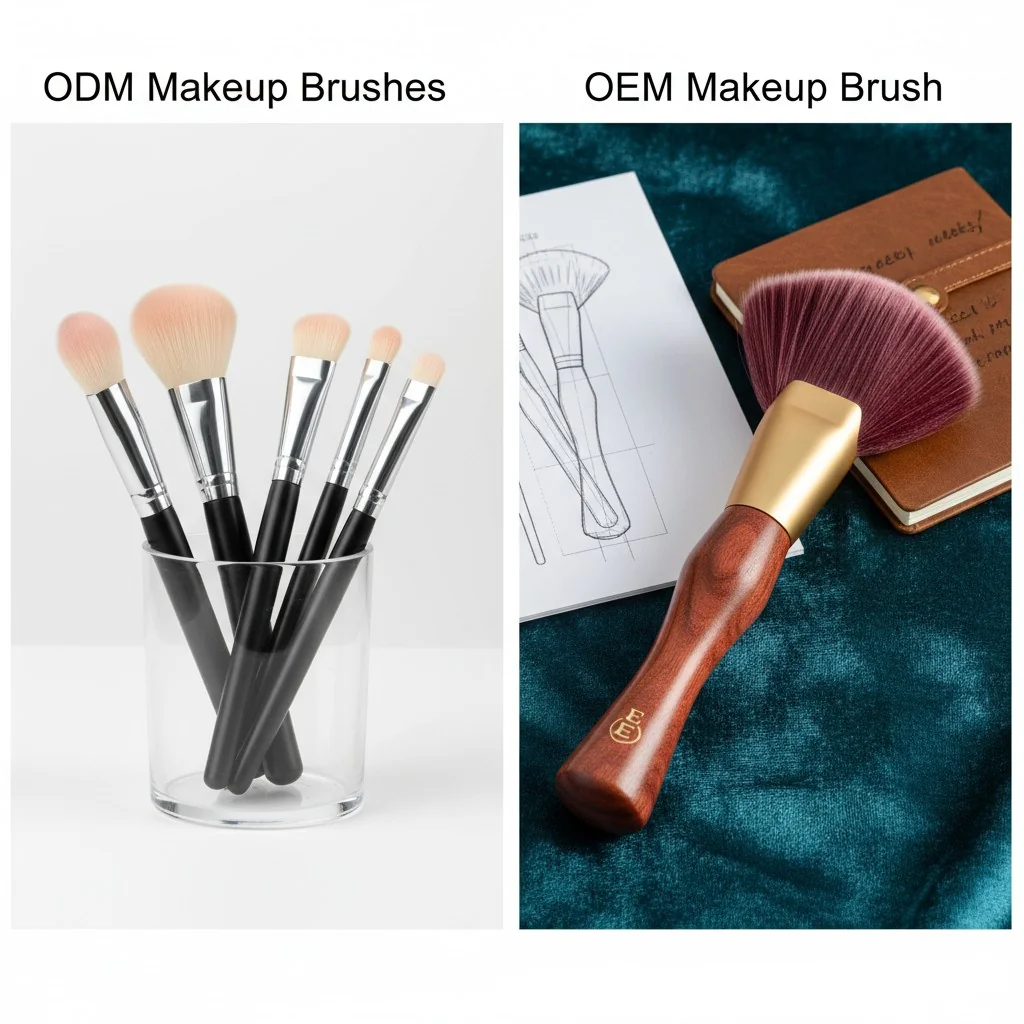

ODM3 (Original Design Manufacturing) lets you choose existing brush designs and add your logo, which is fast and has a low MOQ. OEM (Original Equipment Manufacturing) means creating a unique brush from scratch, which takes longer and costs more but gives you an exclusive product.

I talk to brand founders like you every day. The first thing we always discuss is this choice. It shapes your entire project, from your budget to your launch date. Think of it this way: ODM is like picking a beautiful, ready-made template for your website. You can change the colors and add your content, and it goes live quickly. OEM is like hiring a developer to code a completely custom website from the ground up. It’s 100% unique to you, but it requires more time and investment. Neither is better than the other; they just serve different goals. To help you decide, let’s break down the key differences.

A Simple Decision Framework

| Factor | ODM (Use Factory Designs) | OEM (Create Your Own Designs) |

|---|---|---|

| Goal | Fast market entry, test demand | Brand differentiation, unique IP |

| Uniqueness | Low (logo, color, packaging4) | High (exclusive shape, fibers, finish) |

| Timeline | Fast: ~6-8 weeks to launch | Slower: ~8-14+ weeks to launch |

| Upfront Cost | Low (no mold or tooling fees) | Higher (mold/tooling fees may apply) |

| MOQ | Lower: 100–500 sets is common | Higher: 500–3,000+ units per brush |

If you need to launch within two months and want to protect your cash, start with ODM. Once your brand is established and you have sales data, you can invest in a unique OEM hero brush.

You must always choose OEM to build a successful brand.False

Many successful brands start with ODM to test the market quickly with lower risk and investment. They later introduce OEM products once they have validated customer demand.

Brush Engineering That Sells: Hair, Ferrule, Handle, and Packaging Choices?

You might think a brush is just a brush. But the small details in its construction make a huge difference. Poor materials can lead to shedding, bad makeup application, and unhappy customers. Let’s engineer a brush that performs beautifully and reflects your brand’s quality.

Focus on high-performance synthetic fibers5 that are vegan and easy to clean. Use a tightly crimped aluminum ferrule to prevent shedding. Choose sustainable handles like FSC-certified wood. And finally, use protective, recyclable packaging to ensure your brushes arrive perfectly.

When I was working hands-on in the factory, I learned that a great brush is a system where every part works together. The customer might only notice how soft the bristles are, but they will definitely notice if the brush starts shedding after one wash or if the handle feels cheap. Your customers, especially in the US and EU, are also looking for sustainable and ethical options. The good news is that you don’t have to choose between performance and values anymore. Let’s look at the four key components.

Hair & Fibers: The Heart of Performance

The market has shifted. Your customers want vegan and cruelty-free products. Today’s premium synthetic PBT fibers are incredible. For liquid and cream foundations, we use blends with tapered tips that give a smooth, streak-free finish. For blending powders, we use ultra-soft synthetics that feel just like natural goat hair.

Ferrule & Handle: The Foundation of Quality

The ferrule is the metal part that holds the bristles. We recommend recycled aluminum with very tight crimping to lock the bristles in and prevent shedding. For the handle, FSC-certified wood gives a premium, eco-conscious feel. For more unique ergonomic shapes, injected bio-resins are a great sustainable option.

Packaging: The First and Last Impression

Your packaging protects your investment. A simple recyclable carton with brush guards inside prevents the bristles from getting bent or splayed during shipping. This reduces customer complaints and returns, and it shows that you care about the entire customer experience.

Startup Math That Works: MOQs, Unit Economics, and Lead‑Time Planning?

You need to understand the costs to plan your business, but numbers from factories can be confusing. Without a clear budget, you could run out of cash or set prices that don’t make you any money. I’ll show you the simple math so you can plan your launch with confidence.

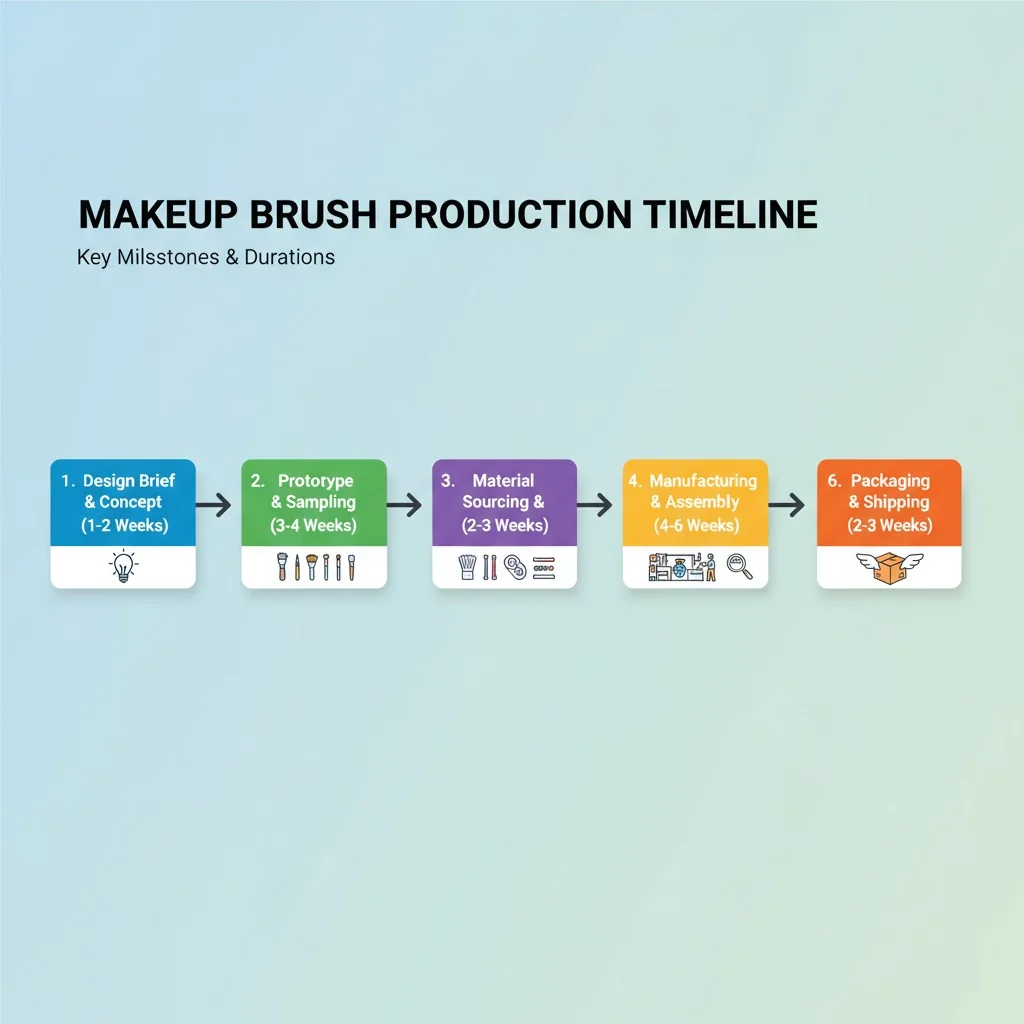

Your costs are driven by materials, customization, and quantity. Expect MOQs of 100-500 sets for ODM and 500-3,000 units per SKU for OEM. Plan for a 30-45 day production lead time after you approve the samples, plus time for shipping.

One of the biggest pain points I hear from founders is a lack of transparency on cost and time. A good manufacturing partner should be clear about this from the start. Let’s map out what you should expect so you can build a realistic business plan. Your final "landed cost" per brush will include the unit price from the factory, shipping, and any import duties6.

Understanding MOQs and Costs

Minimum Order Quantities7 (MOQs) are a big deal for startups.

- ODM MOQs: Often 100 to 500 sets. This is perfect for testing an idea.

- OEM MOQs: Typically 500 to 3,000 units per brush style. This is because custom tools and materials are needed.

Your unit cost will be driven by things like the grade of synthetic fiber, the finish on the handle (e.g., 10 layers of paint vs. 3), and custom packaging.

Mapping Your Timeline

Delayed shipments can ruin a product launch. Here is a realistic timeline:

- Brief & Quoting: 1-2 weeks

- Sampling: ODM samples take about 1-3 weeks. OEM samples can take 3-6 weeks.

- Mass Production: After you approve the final sample, production takes about 30-45 days.

- QC & Shipping: Allow 1 week for final quality control, then add shipping time (from a few days by air to 4-6 weeks by sea).

Starting a makeup brush line costs at least $50,000.False

You can start a small ODM brush line for as little as $2,000 to $11,000. This covers sampling, a small production run, and initial branding, making it accessible for new entrepreneurs.

Compliance and Import Simplified: Tests, Documents, HS Codes, and Ethical Claims?

The words "compliance8," "import," and "duties" can sound very intimidating. You might worry about your products getting stuck at customs or failing to meet regulations. Let’s simplify it. For makeup brushes, the process is more straightforward than you think.

Your brushes need basic component safety checks, like REACH for the EU and Prop 65 considerations for California. You must keep documents to prove claims like "vegan" or "cruelty-free." Your products will be imported under the HS Code category 9603.

One of the worst fears for a new brand owner is having a shipment stopped by customs. Another is getting a letter about a compliance issue. As your partner, we help you prepare the right documents so this doesn’t happen. Many new founders are surprised to learn that even though brushes aren’t makeup, they are still regulated. Here is what you need to know.

Key Regulations in the US & EU

Your factory should be able to provide test reports for the materials used in your brushes.

- In the EU: Components must be screened for substances of very high concern (SVHCs) under REACH regulations.

- In the US: We check materials for restricted substances like heavy metals. If you sell in California, you need to be aware of Prop 65 labeling requirements.

Proving Your Ethical Claims

If you label your brush "vegan" or "cruelty-free," you must be able to prove it.

- Vegan: This relates to the materials. We provide documentation showing no animal-derived components were used in the fibers, glue, or handle finishes.

- Cruelty-Free: This relates to the testing process. It means no animal testing was performed anywhere in the supply chain for the tool itself.

Keep these documents in a file. This is your substantiation.

Getting Your Brushes Home

For import, all products are classified with an HS Code. Makeup brushes generally fall under HS Code 9603.x. Your shipping agent or customs broker will use this code to determine the duty rate you need to pay.

Conclusion

Starting a brush line is a journey of key decisions. By choosing the right manufacturing path, engineering for quality, and planning your finances and compliance, you can build a successful brand.

References

-

Explore resources that guide you through the essential steps to launch your own makeup brush line. ↩

-

Learn about OEM manufacturing and how it can help you create unique products for your brand. ↩

-

Discover how ODM can provide a fast and cost-effective way to enter the market with your products. ↩

-

Explore the significance of packaging in protecting products and enhancing customer experience. ↩

-

Find out why synthetic fibers are preferred for makeup brushes and how they enhance performance. ↩

-

Learn how import duties can impact your overall costs and pricing strategy for your products. ↩

-

Understand MOQs and how they impact your startup costs and production planning. ↩

-

Get informed about the essential compliance regulations for importing and selling makeup brushes. ↩