The term "non-toxic" is used everywhere, but what does it mean for your makeup brushes? Without clear specs, you risk sourcing products that don’t live up to your brand’s promise.

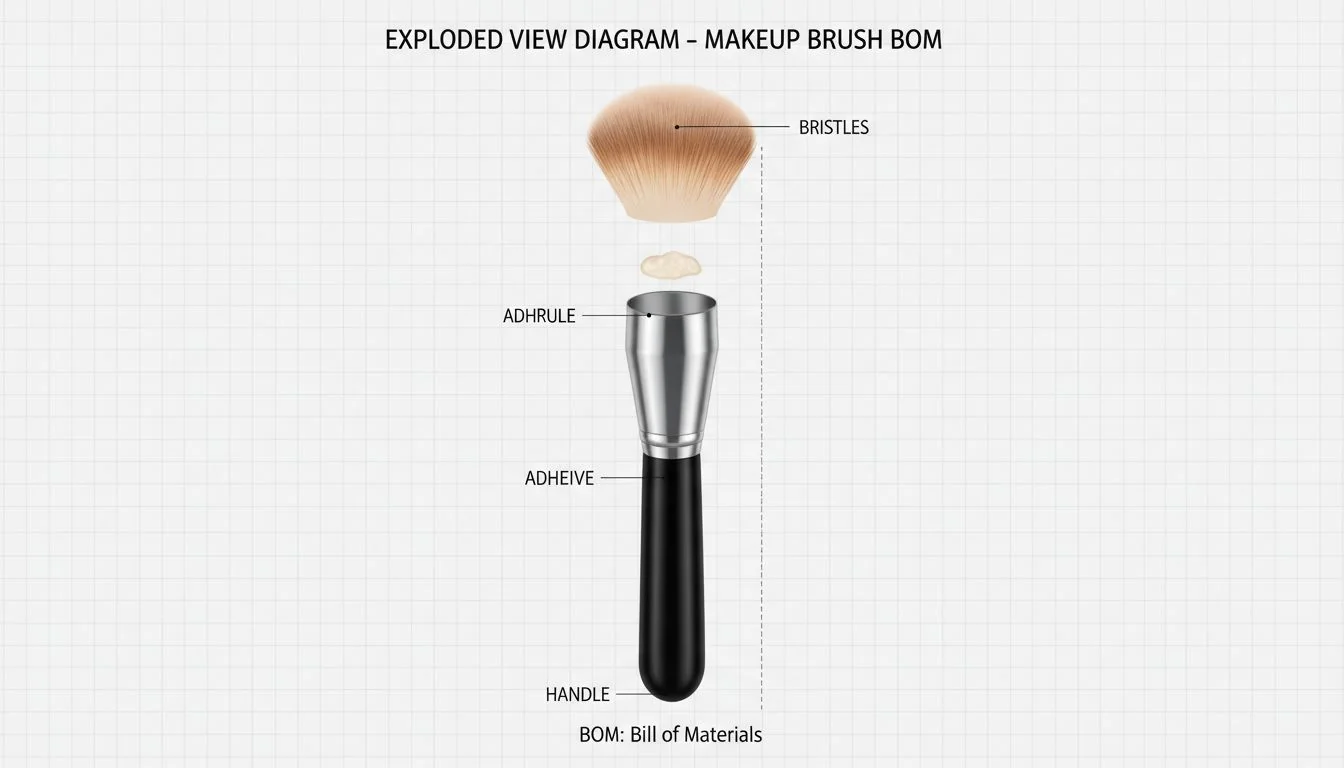

Non-toxic makeup brushes are made from safe, inert components: synthetic PBT/nylon bristles1, corrosion-resistant metal ferrules, REACH-compliant epoxy adhesives, and FSC-certified bamboo or wood handles finished with low-VOC coatings. This bill of materials reduces irritation and supports clean-beauty compliance.

When I first started on the factory floor, I saw firsthand how vague requests led to poor outcomes. A brand would ask for a "good quality" brush, and the factory would interpret that based on cost, not safety or performance. The result? Brushes that shed, smelled of chemicals, or caused skin irritation. This experience taught me that "non-toxic" isn’t a feeling; it’s a technical specification. It’s a checklist you can hand to a manufacturer to ensure the final product is safe, durable, and aligned with your brand values. Let’s break down exactly what that checklist looks like.

Any brush with a bamboo handle is automatically non-toxic and eco-friendly.False

The handle is only one part. The adhesive, ferrule, and bristle materials must also be compliant, and the bamboo should be FSC-certified with a low-VOC finish to be truly sustainable.

A detailed Bill of Materials (BOM) is the foundation for creating a truly non-toxic makeup brush.True

Specifying every component—from the bristle grade to the adhesive type—translates the marketing term 'non-toxic' into a testable, verifiable manufacturing standard.

From Fiber to Ferrule: How Do You Build a Non-Toxic Brush BOM?

You need more than a "non-toxic" label from a supplier. Without a detailed spec sheet, you open the door to inconsistent quality and materials that could harm your brand’s reputation.

A non-toxic Bill of Materials (BOM) specifies high-grade synthetic bristles, a durable metal ferrule, a compliant two-part epoxy adhesive, and a sustainably sourced handle. This blueprint gives you control over the final product and provides a solid foundation for your clean-beauty claims.

A strong BOM is your most powerful tool in sourcing. It removes ambiguity and sets clear expectations with your manufacturer. I’ve seen brands fail because they focused only on the handle material or the bristle softness, forgetting the glue holding it all together. One time, a client’s brushes were falling apart because the factory used a cheap, single-part adhesive that couldn’t withstand a simple water soak test. A proper BOM would have specified a REACH-compliant, two-part epoxy from the start. Let’s build a BOM you can actually use.

Your Non-Toxic Brush BOM Checklist

| Component | Material Specification | Why It Matters |

|---|---|---|

| Bristles | High-grade synthetic PBT/PET/Nylon. Specify fiber grade, diameter, taper ratio, and polish method. | Hypoallergenic, low-porosity (more hygienic), and cruelty-free. Performs exceptionally with liquids and creams. |

| Ferrule | nickel-plated brass2 or copper. Specify alloy and double-crimp parameters. | Resists denting and corrosion, ensuring the brush head is held securely. A double crimp provides extra durability. |

| Adhesive | Two-part epoxy with REACH/Prop 65 compliance. | Ensures strong, water-resistant, and solvent-resistant bonding. Guarantees no restricted or harmful chemicals are used. |

| Handle | FSC-certified wood/bamboo or recycled aluminum. Specify low-VOC waterborne or UV-cured coatings. | Reduces environmental impact and avoids off-gassing from harsh chemical finishes. FSC certification verifies responsible sourcing. |

Natural animal hair bristles are always safer and higher quality than synthetic bristles.False

High-grade synthetic bristles (PBT/Nylon) are hypoallergenic, easier to clean, and cruelty-free. Animal hair can trap bacteria and cause allergic reactions for some users.

Specifying a 'double-crimp' for the ferrule significantly improves a brush's durability and reduces shedding.True

A double crimp creates two secure pressure points on the handle, preventing the ferrule from loosening over time and ensuring the bristles remain tightly packed.

Proof, Not Promises: What Docs and QC Tests Lock in Quality?

Suppliers will often promise quality and compliance. But these promises can be empty, putting your brand at risk if the final product fails to meet customer expectations or regulatory standards.

Lock in quality by requesting a full tech pack, REACH SVHC and Prop 65 declarations, and material certificates like FSC/GRS. Then, you must validate with four key QC tests: shedding, soak, solvent wash, and abrasion before approving mass production.

Trust, but verify. This is my motto in manufacturing. I always tell my clients, like Emily, that documentation is the first step, but physical testing is the final gate. A beautiful certificate means nothing if the brush sheds all over your customer’s face or the logo rubs off after a week. I once worked with a brand that was so excited about their FSC-certified wood handles that they skipped the logo abrasion test. After their first production run, they discovered the "eco-friendly" ink their supplier used rubbed right off with minimal friction. We had to implement a UV-cured ink and an abrasion test (50 cycles with an alcohol-soaked cloth) to fix it. These simple tests protect your investment and your brand’s reputation.

The 4 Essential QC Tests for Your Brushes

| Test | Method | Acceptance Criteria |

|---|---|---|

| Shedding Test | Vigorously stroke the brush 100 times over a contrasting surface. | No more than 2-3 fibers should fall out. |

| 24-Hour Soak Test | Submerge the brush head in water for 24 hours. | No corrosion on the ferrule, no swelling of the handle, and no failure of the adhesive. |

| Solvent Wash Test | Wash the brush head with isopropyl alcohol. | No dye bleeding from the bristles and no weakening of the adhesive bond. |

| Logo Abrasion Test | Rub the logo/printing on the handle with an alcohol-soaked cloth for 50 cycles. | The logo must remain intact with no fading or chipping. |

A supplier's verbal confirmation of 'good quality' is sufficient for starting mass production.False

Verbal promises are not verifiable. Quality must be locked in with a detailed tech pack, material certificates, and passing grades on physical QC tests before you approve a purchase order.

Requesting REACH and Prop 65 compliance documents is critical for brands selling in the EU and US (specifically California).True

These regulations restrict the use of harmful chemicals. Having the declarations on file demonstrates due diligence and ensures your products are legally compliant for these major markets.

Metal Matters: Is Nickel-Plated Brass or Aluminum Better for Your Brush?

The ferrule seems like a small detail in the grand scheme of a brush. But choosing the wrong metal can lead to customer complaints about everything from allergic reactions to a wobbly brush head.

Nickel-plated brass offers superior durability, corrosion resistance, and a secure crimp, making it the industry standard. Aluminum is a lighter, recyclable, and nickel-free alternative, but it’s softer and may dent or loosen more easily. The choice depends on your brand’s priorities.

Choosing the right ferrule is a balancing act between performance, safety, and brand positioning. For most luxury and performance-focused brands, I recommend nickel-plated brass. It feels substantial, holds its shape under the pressure of crimping, and resists rust from repeated washing. This is the workhorse of the industry for a reason. However, I work with more and more brands that prioritize sustainability or cater to customers with metal sensitivities. For them, aluminum is a great choice. It’s highly recyclable and naturally nickel-free. The key is to work with a manufacturer who understands the trade-off. An aluminum ferrule needs to be engineered with the right thickness and crimping technique to compensate for its softness.

Ferrule Material Showdown: Brass vs. Aluminum

| Feature | Nickel-Plated Brass/Copper | Aluminum |

|---|---|---|

| Durability | Excellent. Resists denting and holds a strong crimp. | Fair. Softer and more prone to denting if not engineered properly. |

| Corrosion Resistance | Excellent. The plating protects the metal from water and solvents. | Good. Naturally resistant to rust but can oxidize over time. |

| Nickel Allergy | Potential concern. The nickel plating is inert but can be an issue for highly sensitive users. | Excellent. Naturally nickel-free. |

| Recyclability | Recyclable, but less commonly processed than aluminum. | Excellent. Widely and easily recyclable. |

| Feel & Weight | Heavier, premium feel. | Lighter weight. |

Aluminum is always the best ferrule choice because it is lightweight and recyclable.False

While aluminum has benefits, its softness can lead to a less secure crimp and potential denting. Nickel-plated brass offers superior durability, which is critical for a long-lasting, high-performance brush.

For customers with nickel allergies, aluminum or ferrules with a certified nickel-free plating are the safest options.True

These alternatives eliminate direct contact with nickel, addressing one of the more common metal sensitivities associated with beauty tools.

Sustainability that Sticks: How Do You Verify Eco-Friendly Claims?

"Eco-friendly" and "sustainable" are powerful marketing words. But without proof, they are just greenwashing, which can destroy the trust you’ve built with your customers.

Verify sustainability by demanding documentation. Use Forest Stewardship Council (FSC) certificates for wood and bamboo, and Global Recycled Standard (GRS) for recycled plastics. These verifiable claims build trust and measurably reduce your environmental impact.

Making a truly sustainable product goes beyond just using bamboo. It’s about a verifiable chain of custody. When a client wants an eco-friendly brush line, the first thing I ask for is their target claim. If it’s a "responsibly sourced wood handle," we need to see the supplier’s FSC certificate. If it’s a "handle made from recycled plastic," we need the GRS certificate. These documents are non-negotiable. They are the only way to prove your claims are real. Furthermore, we look at the entire lifecycle. The beauty industry produces around 120 billion units of packaging annually. By creating durable, long-lasting brushes, you’re already fighting that trend. By specifying low-VOC (Volatile Organic Compound) coatings, you’re reducing air pollution during manufacturing. This is how you build sustainability that sticks.

How to Turn Claims into Verifiable Actions

- Demand Certificates: Don’t just take a supplier’s word for it. Ask for a copy of their current FSC or GRS certificate with their company name on it. I help my clients verify these directly with the issuing bodies.

- Specify Low-VOC Finishes: Explicitly request waterborne or UV-cured coatings in your tech pack. These have significantly lower harmful emissions than traditional solvent-based paints.

- Audit for Restricted Chemicals: While PFAS are not typically found in brush materials, it’s wise to perform a full audit of restricted substances across your BOM. This ensures your "clean" and "non-toxic" claims remain accurate and future-proof as regulations evolve.

- Design for Durability: The most sustainable brush is one that doesn’t need to be replaced. Investing in a quality BOM with durable materials like brass ferrules and high-grade epoxy is a sustainability strategy in itself.

PFAS chemicals are a common and significant risk in makeup brush materials like bristles and handles.False

PFAS scrutiny is rising, but these 'forever chemicals' are primarily a concern in cosmetic formulations, not the typical materials used for brush manufacturing. A general chemical audit is still good practice.

Using durable, refillable tool systems can cut packaging-related CO₂ emissions by approximately 60% per refill cycle.True

This data highlights that creating long-lasting products is a powerful and measurable way for beauty brands to improve their environmental footprint, aligning with circular economy goals.

Conclusion

Building a non-toxic brush isn’t about vague promises. It’s about a specific BOM, verified claims, and rigorous testing. You now have the blueprint to source with confidence and deliver excellence.