Your brand promises a flawless, airbrushed finish, but customer reviews mention streaks. The problem might be the brushes you’re sourcing, which look right but don’t perform.

A stippling brush is a duo-fiber face brush1 that applies liquid or cream makeup by tapping (stippling) and lightly swirling, creating an airbrushed, pore-diffusing finish. Choose synthetic PBT fibers, medium tuft density, and a secure ferrule to minimize streaks and shedding for best results.

As a brand founder, you need more than just the consumer-level basics. You need to know how a stippling brush is engineered, how to source it effectively, and what benchmarks to demand from a supplier. I’ve spent years on the factory floor and working with brands like yours, and I know that the small details are what separate a best-selling tool from a clearance-bin disappointment. Let’s go beyond the marketing claims and look at what really creates a high-performance stippling brush, from the fiber specifications to the procurement numbers you need to know.

Global Makeup Brush Market Trends

The demand for high-quality tools is growing fast. This data shows why investing in well-engineered brushes is a smart move for your brand. Different analysts report slightly different numbers, so I’ve included the source and year for clarity.

| Metric | Value | Year | Source |

|---|---|---|---|

| Global makeup brushes market size | ~USD 1.5B | 2023 | DataIntelo |

| Market forecast | ~USD 2.6B by 2032 | 2032 | DataIntelo |

| Cosmetic brush market size | USD 3.72B | 2024 | MRFR |

| Cosmetic brush forecast | USD 6.01B by 2034 | 2034 | MRFR |

| EU product framework | Reg. 1223/2009 | Ongoing | EU Commission |

| Synthetic fiber innovation | PBT/PET + antimicrobial/PCR | 2024 | SY Beauty |

The global makeup brush market is expected to shrink in the next decade.False

Market forecasts from multiple sources, including DataIntelo and Market Research Future, project significant growth, with the market potentially reaching over USD 2.6B to 6B by the early 2030s.

The term 'duo-fiber' refers to a brush with two different lengths of bristles.True

This design is the defining characteristic of a stippling brush, with long fibers to deposit product and short fibers to anchor and diffuse it.

1. What Is a Stippling Brush? Duo‑Fiber Design, Finish, and When It Outperforms Buffing?

You see "duo-fiber" on packaging, but what does it actually mean for performance? Many brushes have the look but fail to deliver, leaving your customers with a streaky, uneven application.

A true stippling brush uses two distinct fiber lengths to achieve its signature finish. The longer, finer fibers pick up and tap liquid or cream product onto the skin’s surface, while the shorter, denser base fibers provide stability and help diffuse the product with light swirls.

The key to a stippling brush is its unique application method. It’s designed for tapping (stippling) first, then using gentle, light swirls to blend. This technique lays product on top of the skin instead of rubbing it in. This is why it’s a game-changer for anyone with skin texture, large pores, or acne scars. It builds coverage without emphasizing unevenness.

So, when should your customers reach for a stippling brush instead of another tool?

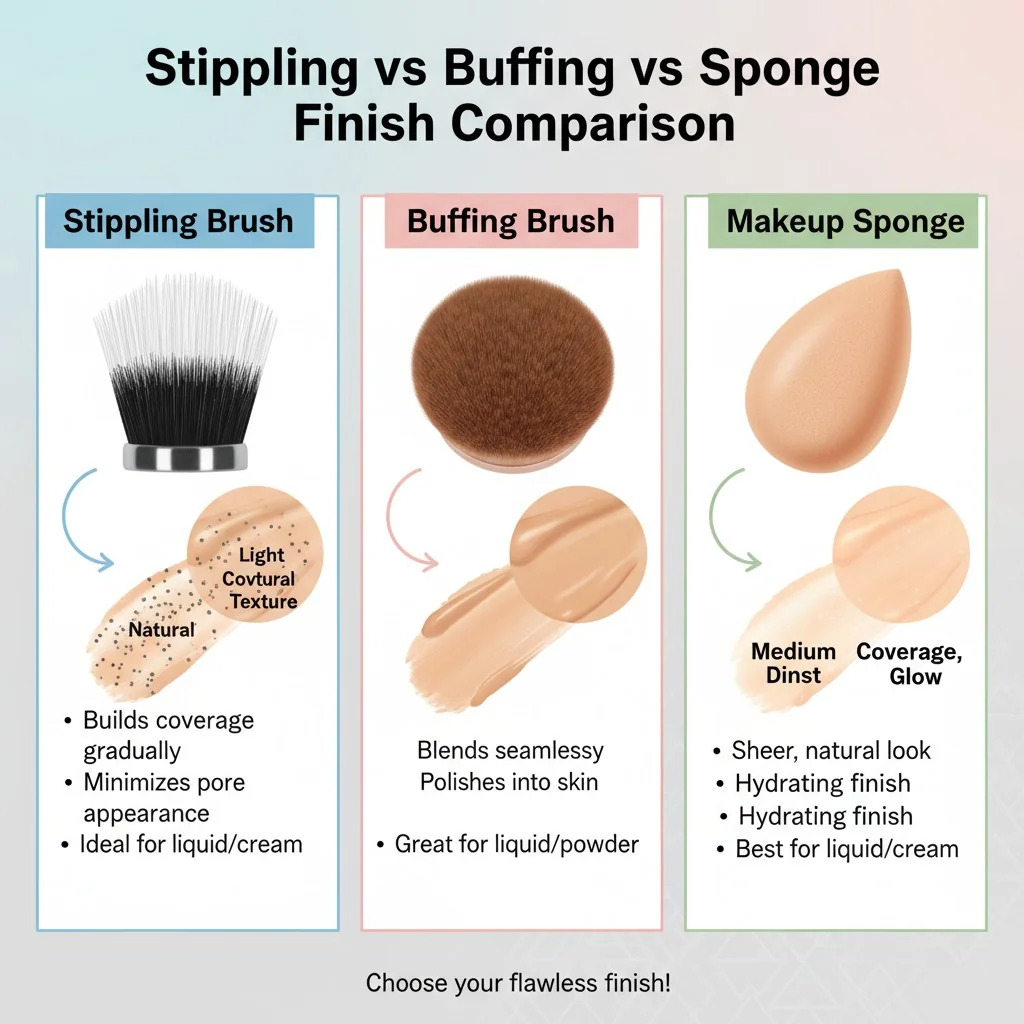

- Versus a Buffing Brush: A buffing brush is dense and designed to be moved in firm, circular motions to work the product into the skin for fuller coverage. Use a stippling brush when you want a more natural, skin-like medium coverage that doesn’t sink into pores.

- Versus a Makeup Sponge: Sponges are great, but they absorb a lot of product and can sometimes lift foundation when blending other creams on top. A stippling brush gives you more control over placement and uses less product to achieve a similar airbrushed effect, especially on dry skin where sponges can sometimes drag.

Stippling brushes are only for applying foundation.False

They are excellent for any liquid or cream product, including blush, bronzer, and highlighter, as the tapping motion allows for precise placement and seamless blending.

The 'airbrushed' finish from a stippling brush comes from laying product on the skin's surface, not rubbing it in.True

The tapping motion deposits product without disturbing skin texture, and the light swirling diffuses it for a poreless look.

2. Engineering the Tuft: Fiber Mix, Density, and Ferrule Adhesives That Create “Airbrush” Coverage?

Your customer’s brush is shedding or the head is wobbly after a few washes. This is a quality issue that damages your brand’s reputation, and it almost always comes down to poor engineering.

To create a brush that delivers an "airbrush" finish and lasts, you must specify the right components. It starts with the fibers and goes all the way to the glue inside the ferrule2. From my experience on the factory floor, this is where good intentions meet reality.

Here is what you need to specify with your manufacturer to ensure performance and durability:

Fiber Selection

The "duo-fiber" look is easy to copy, but the performance is in the material. I recommend using 4th-generation synthetic PBT fibers3 with finely tapered tips. These fibers are less absorbent than natural hair, making them perfect for liquids and creams. They are also vegan and more hygienic. For a performance edge, you can request treatments like antimicrobial coatings to keep the brush fresher for longer.

Tuft Density and Geometry

A stippling brush should have a moderate tuft density. If it’s too dense, it becomes a buffing brush and will drag the product. If it’s too sparse, it will be streaky. The geometry also matters. A flat-top tuft is ideal for foundation application on large areas, while a slightly domed shape gives more control for blush or contour.

Ferrule and Adhesion

The ferrule is the metal part that connects the handle to the head. I recommend anodized aluminum for a good balance of cost and performance, or brass for a more premium, weighted feel. More importantly, you must insist on a waterproof, two-part epoxy adhesive. Many factories cut costs with cheaper glue, which fails after repeated washing. We require a pull test of at least 4–6 kgf for our face brushes to ensure the head stays secure. We also test for shedding, with a standard of fewer than 5 loose filaments per 10 wash cycles.

The weight of the ferrule has no impact on the brush's performance.False

A heavier ferrule, like one made of brass, can improve the brush's balance and control, which is a key selling point for professional makeup artists.

A pull test of 4-6 kgf is a reliable quality assurance benchmark for face brush durability.True

This test ensures the adhesive and crimping are strong enough to prevent the brush head from detaching from the handle during normal use and cleaning.

3. Procurement Benchmarks: MOQs, Lead Times, Sampling, and QA Tests for Stippling Brushes?

You have a brilliant idea for a custom brush, but every supplier you contact quotes a 5,000-piece Minimum Order Quantity (MOQ). This is a major hurdle for indie brands and can kill a product launch before it starts.

Navigating the world of OEM/ODM manufacturing4 requires understanding the industry benchmarks. This knowledge protects you from over-ordering and ensures you get the quality you’re paying for. I built my business specifically to help founders avoid these exact problems.

Here are the typical numbers and standards you should expect:

MOQs and Lead Times

- ODM (Original Design Manufacturing): If you’re choosing a standard brush design from a factory’s catalog and just adding your logo, the MOQ is usually lower. Expect around 500 pieces per style.

- OEM (Original Equipment Manufacturing): For a fully custom brush with unique colors, molds, or materials, the MOQ is higher because the factory has to order these components in bulk. This can range from 1,000 to 5,000+ pieces.

- Lead Times: For an ODM order, expect a lead time of 15–30 working days after you approve the final sample. OEM orders take longer due to tooling and material sourcing. Always factor in a few weeks for sampling and design adjustments.

Strategies to Lower Risk

If a high MOQ is a barrier, talk to your supplier about options. You can sometimes lower the minimum by standardizing components, like using the same handle and ferrule across several different brush head styles. Bundling brushes into a set can also help you meet volume thresholds.

Essential QA Tests

Do not leave quality to chance. Your purchase order should require specific QA checks. I insist on these for my clients:

- Incoming Material Certification: Proof that the fibers are the correct grade of PBT.

- Adhesive Specification: Confirmation that two-part epoxy is being used.

- Performance Tests: Documented results for pull tests (≥4–6 kgf), shedding tests (<5 filaments/10 washes), and 20-cycle wash stability tests.

OEM and ODM have the same MOQ because they are both custom manufacturing.False

ODM uses a factory's existing designs, resulting in lower MOQs (around 500 pcs). OEM involves creating a new product from scratch, which requires higher MOQs (1,000-5,000+) to cover custom tooling and materials.

A typical lead time for a standard ODM brush order is 15-30 working days after sample approval.True

This is an industry-standard timeframe for producing brushes using existing components and designs.

4. Compliance & Sustainability: Vegan Fibers, PCR Options, and EU/US Documentation Buyers Need?

Making claims like "vegan," "cruelty-free," or "eco-friendly" is a powerful marketing tool. But making these claims without proper documentation is a huge risk that can lead to legal issues and destroy customer trust.

As a brand founder selling in the US or EU, you are responsible for the claims you make. It’s not enough for your supplier to simply say a product is compliant; you need the paperwork to prove it. This is an area where I see many new brands get into trouble.

Let’s clarify what you need to ask for:

EU & US Compliance

In the EU, makeup brushes are considered "beauty accessories." While they don’t fall under the full scope of the cosmetics regulation (EC) No 1223/2009 in the same way a foundation does, any claims you make on your packaging or marketing must be truthful and verifiable. If you sell a brush as part of a kit with a cosmetic product, the entire kit must be compliant, which includes having a designated Responsible Person, a Product Information File (PIF), and notification in the CPNP portal.

Verifying Your Claims

- "Vegan" & "Cruelty-Free": These claims refer to materials and testing. For a brush to be vegan, it must contain no animal hair or animal-derived products in its components (like certain glues). For it to be cruelty-free, no part of it can be tested on animals. You must get a signed declaration from your supplier confirming these facts.

- "Sustainable" Materials: If you want to claim your brush uses recycled materials, ask for specifics. For example, specify PCR-PBT fibers and ask for the percentage of post-consumer recycled content. If you use wood handles, request FSC-certified wood to ensure it comes from responsibly managed forests. I always provide my clients with the raw material certifications so they can market their products with full confidence.

Makeup brushes sold in the EU must be registered in the CPNP portal.False

As beauty accessories, brushes alone do not require CPNP notification. However, if sold in a kit with a cosmetic product, the entire kit must be registered.

To claim a brush handle is sustainable, you should request FSC certification from your supplier.True

FSC (Forest Stewardship Council) certification is a globally recognized standard that verifies wood is sourced from forests managed in an environmentally and socially responsible way.

Conclusion

Mastering the stippling brush is about understanding its engineering, procurement, and compliance. You now have the expert insights to source with confidence and deliver a truly flawless tool to your customers.

References

-

Understanding the mechanics of duo-fiber brushes can enhance your makeup application techniques. ↩

-

Understanding the ferrule’s function can help you choose brushes that last longer and perform better. ↩

-

Learn about the advantages of synthetic PBT fibers for durability and performance in makeup brushes. ↩

-

Gain insights into manufacturing processes to make informed decisions for your brand’s products. ↩