Sourcing US-made makeup brushes feels like a maze. You waste time vetting vendors who can’t meet your quality standards, leaving your brand launch stalled and over budget.

For a US-based partner, shortlist Anisa (GA), TaikiUSA (NJ), FM Brush (NY), Color Strokes (NY), and Audrey Morris (FL). Compare them on MOQs1 (plan for 500–2,000 units/SKU), cruelty-free fibers, finish quality, compliance (ISO/GMP), sampling speed, and price tiers to find your best fit.

Finding a name on a list is easy. But as someone who started on the factory floor, I can tell you that finding the right manufacturing partner is about much more. It’s about matching a factory’s real capabilities—from their fiber sourcing to their ferrule adhesive2—with your brand’s vision. A great partner de-risks your launch; a bad one can sink it. Let’s look beyond the sales pitch and get into the details that actually matter for your business.

Over 90% of makeup brushes sold in the USA are manufactured in China.True

The vast majority of global brush production, including components for many 'Made in USA' assembled products, is centered in China due to its established supply chains, skilled labor, and cost efficiencies.

All brushes labeled 'Made in USA' are 100% sourced and produced domestically.False

The 'Made in USA' label can apply to products that are merely 'assembled' in the US using imported components. True end-to-end US manufacturing is extremely rare and costly for makeup brushes.

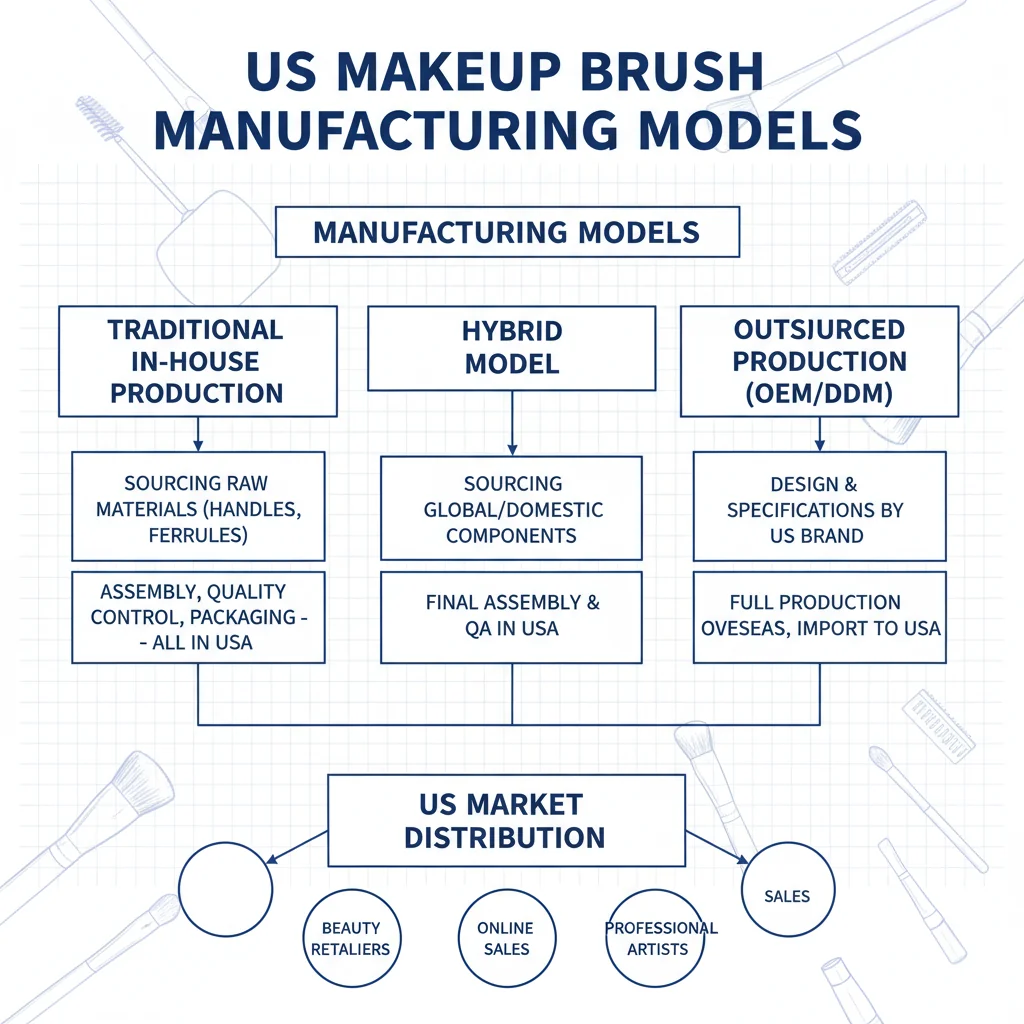

What counts as a “US makeup brush manufacturer” in 2025?

The "Made in USA" label can be confusing. You might pay a premium for a brush that’s only assembled in the US with globally sourced parts, affecting your cost structure.

A "US makeup brush manufacturer" can mean a company that fully produces brushes domestically (rare), assembles imported components in the US, or a US-based company3 that manages its own overseas factories. Understanding this difference is key to managing costs, quality, and your supply chain strategy.

When you’re sourcing, you need to know exactly what you’re paying for. The term "US manufacturer" isn’t as straightforward as it sounds. From my experience working with brands all over the world, I’ve seen how these distinctions can impact everything from your final price to your marketing claims. Let’s break down what you’ll typically find.

Three Tiers of "US Manufacturing"

-

Assembled in USA: This is the most common model. The individual components—like the synthetic PBT fibers, the aluminum ferrules, and the wooden handles—are often produced overseas (usually in Asia) where the specialized supply chain is robust. Then, the final brush is assembled, finished, and packaged at a facility in the United States. This gives you a "Made in USA" claim for assembly but leverages global cost efficiencies for parts.

-

US-Based Company, Overseas Production: Some well-known US companies, like TaikiUSA, operate with a US headquarters for sales, service, and R&D, but their primary manufacturing facilities are located overseas. This model gives you the benefit of US-based communication, contracts, and quality control4 standards, but with the production scale and cost structure of a global manufacturing hub.

-

Fully US-Made: This is the rarest and most expensive category. It means every part of the brush, from the raw materials for the handle to the extrusion of the bristles, is sourced and manufactured within the United States. This is typically reserved for highly specialized or luxury niche products where the cost is secondary to the "100% Made in USA" story.

For most indie brands, understanding this difference helps you ask the right questions. You can decide if your priority is a US assembly claim, the service level of a US-based team, or the most competitive price point.

Synthetic brush fibers like PBT and Taklon were originally developed by DuPont™ in the United States.True

DuPont™ pioneered the development of high-performance synthetic filaments like Nylon and Taklon, which became the foundation for modern, cruelty-free makeup brush bristles.

US-based brush assembly guarantees faster lead times than overseas production.False

While domestic shipping is faster, overall lead times can still be long if the US assembler is waiting on imported components that face shipping delays or customs clearance issues.

Shortlist: reputable makeup brush manufacturers in the USA?

You need a list of trusted US vendors now. Searching online gives you endless, unvetted options, mixing B2B suppliers with direct-to-consumer brands, which wastes your valuable time.

Start your search with Anisa International (GA), TaikiUSA (NJ), FM Brush (NY), Color Strokes/Brushes by Karen (NY), and Audrey Morris Cosmetics (FL). These are established OEM/ODM partners known for quality, compliance, and serving professional beauty brands.

Having a shortlist is the first step. The next is to evaluate them like a pro. I’ve seen brands get excited by a beautiful sample, only to have the bulk order fail on quality control. The secret is to look at the technical details. Ask about the ferrule adhesive and the curing process—this is a primary cause of shedding that many brands overlook. Approve "golden samples" under multiple lighting conditions to catch finish defects. These are the small things that de-risk your entire investment.

Here is a starting point for your due diligence.

Top US Makeup Brush OEM/Private Label Candidates

| Vendor | Location | Brush Focus | Cruelty-Free/Vegan | Known For |

|---|---|---|---|---|

| Anisa International | Atlanta, GA | Skincare & Makeup Brushes | Yes, strong focus | Patented fiber technology, innovation, serving major brands. |

| TaikiUSA | Montvale, NJ | Makeup Brushes, Sponges | Yes | Global manufacturing network, large-scale production, stock & custom. |

| FM Brush | Queens, NY | Art & Cosmetic Brushes | Yes | Long history, extensive style library, luxury and professional lines. |

| Color Strokes | Ronkonkoma, NY | private label5 Brushes | Yes | Full-service private label, brush sets, quick turnaround on stock items. |

| Audrey Morris | Pompano Beach, FL | Cosmetics & Brushes | Yes | Turnkey private label solutions for makeup and tools, low entry barrier. |

When you contact them, don’t just ask for a catalog. Send a detailed Request for Quote (RFQ) that specifies your desired fiber type (e.g., tapered PBT), handle material, and finish. This shows you’re a serious buyer and helps you get an accurate quote faster.

Anisa International holds over 30 patents for its makeup brush designs and fiber technology.True

Anisa is a leader in brush innovation, with numerous patents covering unique brush head shapes, fiber bundles, and manufacturing processes that are recognized across the beauty industry.

All US brush manufacturers offer MOQs below 250 units for custom brushes.False

While some may offer low MOQs on existing stock items, custom brush production in the US typically requires higher minimums (often 500-2,000+ units) to cover setup and labor costs.

What are typical MOQs and price ranges for US‑made brushes?

You need to know if you can afford US manufacturing. Vague pricing and high Minimum Order Quantities (MOQs) can stop your project before it starts, making it hard to budget.

For US-made private label brushes, plan for MOQs in the 500–2,000 unit range per SKU. Entry-level pricing for a simple synthetic brush may start around $1.50-$3.00, but this increases quickly with customization, higher-grade fibers, and complex finishes.

Price is always a major factor, especially for a growing brand. While some online articles mention MOQs as low as 250 units, my experience shows this is more common with overseas suppliers or for very basic, in-stock items. In the US, where labor and operational costs are higher, the numbers look a bit different. It’s important to understand what drives the price up so you can make smart choices for your budget.

Key Cost Drivers for US Brushes

- Labor: This is the single biggest cost difference between US and Chinese manufacturing. Assembling, finishing, and quality checking brushes by hand is an intensive process, and US labor rates are significantly higher.

- Customization: Using a manufacturer’s existing brush head mold and handle shape is the most affordable route. Creating a new, custom mold for your unique design requires a separate tooling investment that can cost thousands of dollars, which you have to factor into your unit price.

- Materials & Finishes: The type of synthetic fiber matters. A basic PBT filament is cheaper than a specialized, patented fiber. Likewise, a simple painted handle is more cost-effective than a soft-touch finish, a high-gloss lacquer, or a weighted handle.

A pro tip for managing costs: if you’re creating a brush set, try to standardize the handle and ferrule across all the brushes. Using the same components for different brush heads reduces tooling costs and simplifies the assembly line, which can lower your per-unit cost.

The cost of a makeup brush is 80% determined by the handle material.False

While the handle is a factor, the brush head (bristle type, density, and shaping) and the ferrule (material and crimping process) are often more significant cost drivers, along with labor.

Custom tooling for a unique brush head shape can cost between $1,000 and $5,000.True

Creating a new mold for a custom brush head is a one-time NRE (Non-Recurring Engineering) cost that varies based on complexity, but it typically falls within this range for most OEM manufacturers.

Why choose Chinese cosmetics suppliers over U.S. vendors?

US manufacturing seems faster and safer, but is it always the best choice? You might be sacrificing cost-effectiveness, innovation, and the exact custom design you envisioned for your brand.

Chinese suppliers often provide superior cost-performance, vast material libraries, and unmatched customization flexibility. For brands focused on unique aesthetics and value, a vetted Chinese partner can be a more powerful and strategic choice for growth.

As someone who built a business from the ground up in the heart of the Chinese brush manufacturing industry, I know the stereotypes. But I also know the reality. The right Chinese partner isn’t just a factory; they are a strategic resource for growth. For a brand founder like Emily, who cares deeply about unique packaging and cruelty-free materials but is also sensitive to cost, China often provides the best of all worlds. Many of my clients in the U.S. and Europe choose us specifically because they can’t get the same level of customization at a viable price point anywhere else.

Let’s look at a direct comparison.

Sourcing Strategy: USA vs. China

| Factor | US Vendors | Chinese Vendors (like Brushino) |

|---|---|---|

| Cost | Higher unit cost due to labor. | Lower unit cost, enabling better margins or competitive pricing. |

| MOQ | Typically higher (500-2,000+). | More flexible; often lower (e.g., 500 units) to support indie brands. |

| Customization | Often limited to stock options to control costs. | Nearly limitless. The entire supply chain is built for custom shapes, colors, and finishes. |

| Innovation | Strong in patented fiber tech. | Fast at adopting trends and developing unique designs from a global perspective. |

| Communication | Easy, same time zone. | A professional partner will have fluent English-speaking staff and be highly responsive. |

The biggest pain point I hear from new clients is that other factories didn’t take their small brand seriously. At Brushino, we built our business by helping indie brands launch. We provide design support, transparent communication, and the documentation you need (like Vegan and Cruelty-Free certs) because I know those are the things that keep you up at night. Choosing a supplier isn’t about geography; it’s about finding a partner who is as invested in your brand’s quality and success as you are.

China produces an estimated 80% of the world's makeup brushes.True

China's comprehensive industrial ecosystem for cosmetics tools, from raw material processing to final assembly, makes it the dominant global leader in makeup brush manufacturing by a large margin.

All Chinese factories have poor communication and slow response times.False

This is a common stereotype. Professional, export-oriented OEM/ODM factories like Brushino prioritize clear, fast English communication and have dedicated project managers to serve international clients.

Conclusion

Choosing a manufacturer, whether in the US or China, requires a clear strategy. Evaluate partners on cost, quality, and customization to find the best fit for your brand’s goals.

References

-

Understanding MOQs helps you budget effectively and plan your inventory for a successful launch. ↩

-

Learning about ferrule adhesive can prevent quality issues and ensure your brushes perform well. ↩

-

Understanding the benefits of US-based companies can improve communication and quality control. ↩

-

Learning about quality control can help you avoid costly mistakes and ensure product consistency. ↩

-

Understanding private label options can open up new business opportunities for your brand. ↩