Sourcing makeup brushes can feel like a black box. You worry about shedding1, loose handles, and if the quality will truly represent your brand. This uncertainty can be stressful.

Makeup brushes are made by preparing bristles (synthetic PBT2 or animal hair), bundling and shaping them, gluing the root, and crimping a metal ferrule. A finished handle is attached, then the brush is trimmed and tested for shedding and pull strength. A quality brush passes through about 80 steps.

When I first started working on the factory floor, I was amazed at how many steps go into making a single brush. It’s not just about sticking some hairs on a handle. It’s a detailed process where every stage impacts the final performance. For brand founders like you, knowing these steps is key to sourcing with confidence and avoiding common pitfalls. Let’s pull back the curtain and break down exactly how a professional makeup brush comes to life.

The global makeup brush market was valued at USD 7.0 billion in 2024.True

According to market research, the makeup tools market is substantial and growing, projected to reach USD 12.9 billion by 2034 at a 6.3% CAGR.

A high-quality makeup brush is made in under 10 steps.False

A qualified brush actually goes through approximately 80 distinct process steps, from preparing the raw fibers to final quality control and packaging.

Materials to Performance: What Is Each Part of a Brush Actually Made Of?

You see terms like "PBT," "Taklon," and "FSC-certified," but what do they mean for performance? Choosing the wrong material can lead to poor application or a brush that doesn’t match your brand’s values.

A brush has three parts: bristles, ferrule3, and handle. Bristles are mostly synthetic PBT or sometimes animal hair. Ferrules are usually aluminum or brass. Handles are often wood, bamboo, or plastic. Each choice affects performance, cost, and your brand’s story.

When I work with brand owners, the first thing we discuss is materials. The right choices here define everything from how the makeup applies to how the customer feels about your brand. It’s about balancing performance, aesthetics, and ethics. For example, a client focused on a luxury powder foundation might consider natural hair, but if their brand is strictly vegan, we’d look at advanced synthetic fibers that mimic natural hair’s pickup. Let’s look at each component.

Bristles: The Heart of the Brush

This is the part that touches your customer’s skin. Synthetic bristles, usually PBT (also known as Taklon), are the industry standard now. They are cruelty-free4, durable, and great for liquid or cream products. We make them by melting polymer pellets, extruding them into thin fibers, and tapering the ends for softness. More advanced synthetics, like MCF, are engineered to have microscopic structures that mimic the scales on natural hair, improving powder pickup. Natural animal hair (like goat or squirrel) is still used for its excellent powder-holding ability, but its sourcing is controversial and hard to trace, making "cruelty-free" claims difficult to verify.

Ferrules: The Unsung Hero

The ferrule is the metal part that connects the bristles to the handle. Most are made of aluminum because it’s lightweight and cost-effective. For premium brushes, we use brass or copper. They are heavier, feel more luxurious, and have better corrosion resistance. The ferrule is critical for preventing shedding—a poor crimp is a primary cause of loose bristles.

Handles: The Final Touch

Handles are typically made from wood, like FSC-certified birch, which ensures it comes from a responsibly managed forest. Bamboo is another popular sustainable option. For a different feel, we can also use aluminum or recycled plastics. The finish is just as important. We apply multiple layers of primer and paint, with drying cycles in between. This process removes odors and ensures the color is stable and won’t chip.

| Component | Common Materials | Typical Process Highlights | Key QC Metric |

|---|---|---|---|

| Bristles | PBT/Taklon, MCF; Goat/Pony | Extrusion/Tapering/Dyeing; Sorting/Shaping | Diameter Tolerance, Shedding Rate |

| Ferrule | Aluminum, Brass/Copper | Extrusion, Cutting, Plating/Anodizing | Roundness, Crimp Force |

| Handle | FSC Birch, Bamboo, Plastic | Sanding, Priming, Multi-Coat Painting | Paint Hardness, Odor Release |

All animal-hair brushes are certified cruelty-free.False

Traceability and welfare oversight in the animal hair industry are often weak, making cruelty-free claims difficult to verify. Many experts and brands prefer synthetic fibers for guaranteed cruelty-free status.

Synthetic PBT fibers are also known as Taklon.True

Taklon is a common trade name for high-quality, synthetic PBT (polybutylene terephthalate) fibers used in cosmetic and art brushes.

From Fiber to Finished Brush: What Are the 8 Essential Factory Stages?

You’ve approved a sample, but what really happens during those 60 days of production? A lack of transparency can hide shortcuts that only show up when customers complain about shedding or loose handles. Let’s fix that.

The process starts with preparing bristles and shaping the bundle. Then, we glue the root, crimp the ferrule, finish the handle, assemble the parts, trim the head, and run final QC checks5. These are the core steps to a perfect brush.

I’ve seen it all on the factory floor. The difference between a brush that lasts for years and one that falls apart in a month comes down to the small details in the production line. A brand’s reputation is built on these details. Here is the 8-stage journey your brush takes from raw material to a product you can be proud of.

- Bristle Sourcing and Preparation: We start with the fibers. Synthetic fibers are extruded and tapered to create soft tips. Animal hairs are cleaned, sorted by quality, and shaped with heat.

- Bundle Forming and Shaping: Workers weigh a precise amount of bristles for each brush. They then hand-shape the bundle in a special mold to create the desired head shape—whether it’s a fluffy powder brush or a dense foundation brush.

- Glue Dosing and Root-Setting: This is a critical step to prevent shedding. A controlled dose of strong adhesive is applied to the base of the bristle bundle. The glue is then cured to create a solid, secure root. This is where many factories cut corners, but we know it’s non-negotiable.

- Ferrule Pressing and Crimping: The glued bristle bundle is inserted into the metal ferrule. A machine then presses the ferrule into its final round shape and crimps it tightly, locking the bristles in place.

- Handle Finishing and Odor-Off: While the brush heads are being made, the handles go through their own process of sanding, priming, and painting. They are painted and dried in multiple cycles to create a durable, odorless finish.

- Assembly and Logo: The finished brush head (bristles + ferrule) is glued onto the handle. Your brand’s logo is then applied using methods like laser engraving, silk-screening, or hot stamping.

- Trimming and Final Shaping: Even after shaping, some stray fibers might exist. We carefully trim the brush head to refine its contour and ensure a perfect shape.

- QC and Packaging: Every single brush goes through a final inspection. We check dimensions, test for shedding, and perform pull tests on the bristles. After cleaning, the brushes are ready for packaging.

The shape of a brush head is created only by trimming the bristles.False

The primary shape is created when workers form the bristle bundle in a mold. Trimming is a final refinement step, not the main shaping process.

Proper glue dosing and curing is critical for preventing brush shedding.True

Controlling the amount of adhesive and allowing it to cure properly creates a strong bond at the bristle root, which is the most effective way to stop bristles from falling out.

Quality and Compliance: How Do Factories Prevent Shedding, Loosening, and Defects?

You need proof that your brushes are high-quality and meet standards like "cruelty-free." Receiving a bulk order full of shedding brushes or getting called out for false "vegan" claims can destroy your launch and your brand’s credibility.

Good factories control quality with fiber checks, precise glue and crimping, and specific tests like pull-strength, shedding, and bake tests. For compliance, they use certified materials like FSC wood and vegan fibers, ensuring full traceability for your claims.

For brand founders like Emily, trust is everything. She needs to know that what she’s promised her customers is what she’s delivering. That’s why I’m so strict about our QC process. It’s not just about a final check; it’s about building quality in at every stage. We also provide the paperwork to back it up. If we say a brush is vegan and uses FSC-certified wood, you get the certificates. Here are the key controls we implement.

Core Quality Controls

To prevent common defects, we focus on a few key areas. We check fiber uniformity to ensure softness and consistency. We use bundle metering (weighing) to guarantee every brush has the same density. For the glue, we control its viscosity and cure time to create the strongest possible bond. When crimping the ferrule, we measure the crimp force to ensure it’s tight enough without damaging the handle. Finally, every batch undergoes a series of tests:

- Pull-Strength Test: We use a tool to pull on the bristles to ensure they are firmly rooted.

- Shedding Test: We manually brush and tap the head to check for any loose fibers.

- Bake Test: We bake brushes at a high temperature to ensure the glue and paint can withstand hot climates or storage conditions.

Environmental and Safety Compliance

Compliance is just as important as quality. Many finishing processes, like plating and anodizing ferrules, have environmental impacts. We work with certified partners who manage this responsibly. During painting, we use systems to control fumes. Most importantly, we focus on material certifications. For brands that value sustainability and ethics, we provide documentation for FSC-certified handles, recycled aluminum ferrules, and vegan bristles. This transparency is essential for building a trustworthy brand. For cruelty-free claims, synthetic fibers are the only way to be 100% certain, as the animal-hair supply chain lacks reliable oversight.

FSC certification ensures that wood for brush handles comes from responsibly managed forests.True

The Forest Stewardship Council (FSC) is a global organization that certifies forests based on rigorous environmental and social standards.

Bake tests are done to check the color of the bristles.False

Bake tests are a quality control measure to ensure the adhesive and paint on a brush can withstand high temperatures without failing, which is important for shipping and storage.

Timelines and Costs: What Should You Expect for Sampling, MOQs, and Production?

You need to plan your launch, but factory timelines and costs are often vague. Unexpected delays can make you miss a seasonal sales window, and hidden costs can wreck your budget. Let’s get you some real-world numbers.

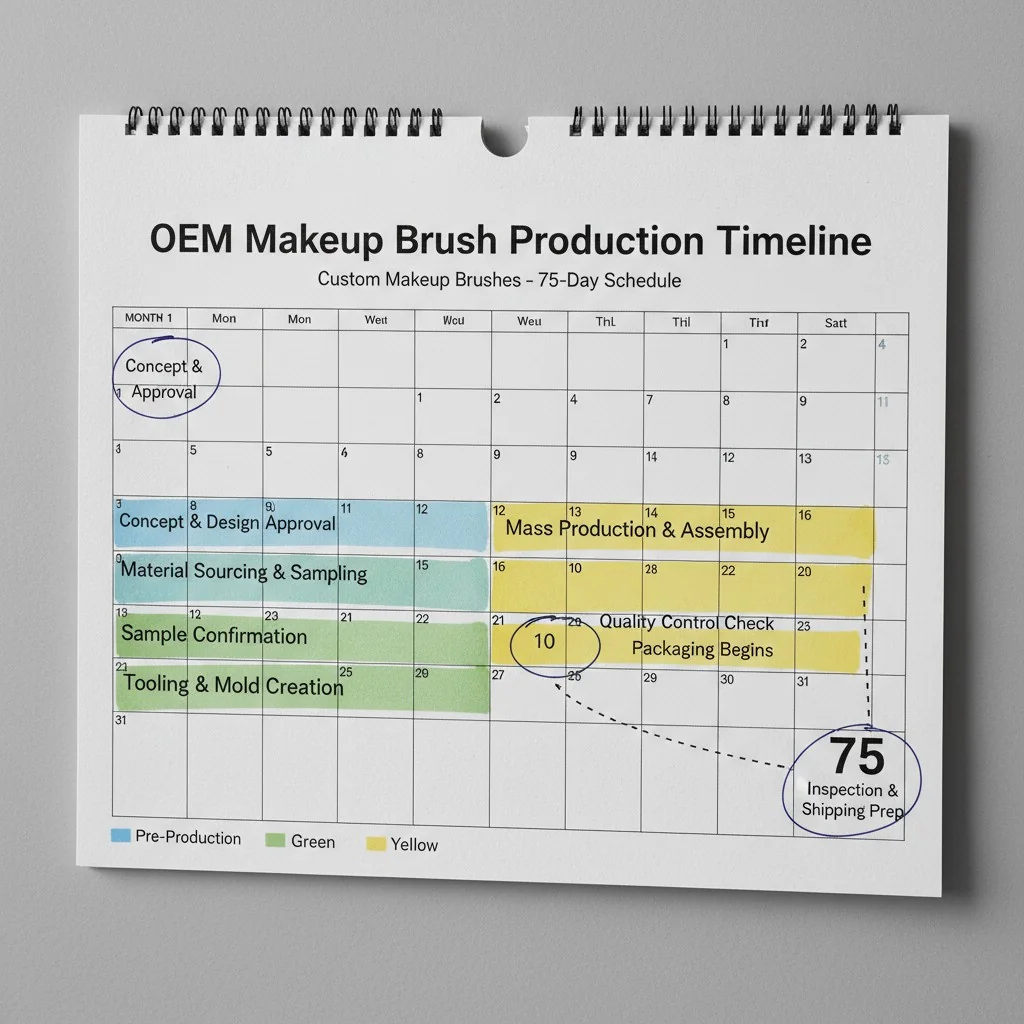

For custom brushes (OEM), expect samples in about 2 weeks and mass production in 60–75 days after you approve the sample. ODM, where you modify a factory’s existing design, is faster and often allows for lower MOQs.

I know how critical launch dates are for my clients. A delay of a few weeks can mean missing Black Friday or a key holiday season. That’s why I believe in being completely transparent about timelines from the very beginning. Here’s a realistic breakdown of what to expect when you’re sourcing brushes.

Sampling and Production Lead Times

In a well-run factory, creating a custom sample based on your design should take about 2 weeks. This can vary if you need a completely new mold for a handle or a custom fiber color. Once you approve the final sample and make a deposit, mass production typically takes 60–75 days. This timeline accounts for sourcing all the raw materials, the ~80 manufacturing steps, and final QC. Complex projects with special finishes, like plated brass ferrules or unique handle shapes, might take longer.

OEM vs. ODM

Understanding the difference between OEM and ODM is key to managing your timeline and budget.

- OEM (Original Equipment Manufacturer): This is where we build a brush entirely to your unique specifications—your shape, your materials, your finishes. It offers complete brand control but usually involves higher development costs, longer timelines (if new molds are needed), and higher MOQs.

- ODM (Original Design Manufacturer): This is where you choose from our existing catalog of brush designs and customize them with your logo, colors, and packaging. It’s much faster, has lower MOQs, and is a great way for new brands to get to market quickly without sacrificing quality.

I always tell new founders that there’s no right or wrong choice. It depends on your brand strategy, budget, and timeline. My job is to provide the options and the expertise to help you make the best decision for your business.

ODM is always cheaper than OEM.False

While ODM often has lower initial costs and MOQs, a high-volume OEM order can sometimes achieve a lower per-unit cost. The best choice depends on volume, customization needs, and speed-to-market.

A typical mass production run for custom makeup brushes takes about one month.False

A standard lead time for mass production is 60–75 days after sample approval, as it involves sourcing materials, numerous manufacturing steps, and thorough quality control.

Conclusion

From fiber to ferrule, making a great brush involves many steps. Understanding this process helps you source smarter, protect your brand, and launch new products with total confidence.

References

-

Learn about the factors that contribute to shedding in makeup brushes and how to prevent it. ↩

-

Explore the benefits of synthetic PBT fibers in makeup brushes, including their durability and cruelty-free status. ↩

-

Discover how the ferrule affects the performance and durability of makeup brushes. ↩

-

Understand the importance of cruelty-free claims and how they impact consumer trust in makeup products. ↩

-

Learn about the final quality control checks that ensure each makeup brush meets high standards before packaging. ↩