Choosing the right synthetic fiber1 feels complicated. The wrong choice can ruin your brush’s performance, hurt your brand’s image, and waste your budget. I’ll break it down for you.

Most modern synthetic makeup brushes are made from extruded polyester fibers, primarily PBT2 (polybutylene terephthalate), often marketed as Taklon. PET and nylon are also used, with recycled PBT/PET options emerging for sustainable lines. The fiber’s performance depends on its material, diameter, and engineering.

When I first started on the factory floor, I was amazed at how a simple-looking "plastic" fiber could be engineered into so many different forms. One brush could feel silky soft for powder, while another, made from a similar base material, was firm and perfect for eyeliner. It taught me that the real magic isn’t just the polymer name, but the science behind how the fiber is shaped and treated. Understanding these details is the key to moving from a generic product brief to creating a truly high-performance tool that your customers will love. Let’s dive into the specifics so you can write your next OEM brief with total confidence.

All synthetic brush fibers are a form of plastic.True

Synthetic bristles are made from polymers like PBT, PET, or nylon, which are all types of plastic.

The term 'vegan brush' specifies the exact material used.False

'Vegan' simply means the brush contains no animal-derived components. It does not specify the type of synthetic polymer, such as PBT or nylon.

What polymers are used in synthetic makeup brush bristles (PBT, PET, or nylon)?

You see the word "synthetic" on every brief, but what does it actually mean? This lack of detail makes it impossible to compare supplier quotes or guarantee your brush’s performance.

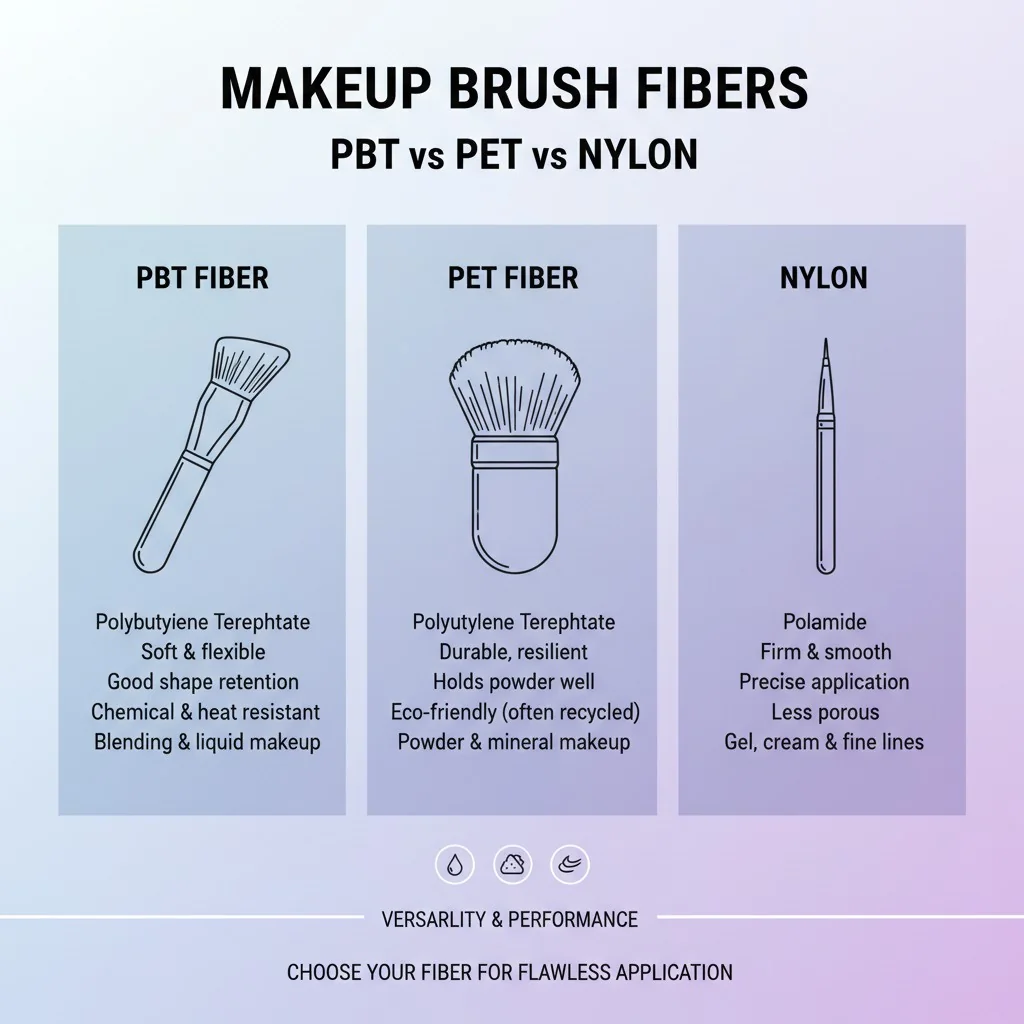

The three main polymers are PBT, PET3, and nylon. PBT (often called Taklon) is the modern standard for premium brushes due to its superior softness and durability. PET is a stiffer alternative, while nylon is an older material now less common in high-end face brushes.

In my factory, we work with these materials every day. The choice of polymer is the first and most critical decision in brush design. It sets the foundation for everything else—how the brush feels, how it picks up product, and how long it lasts. While they are all "plastics," they behave very differently. A brand owner needs to know these differences to spec a brush that truly matches their product formula and brand promise. For example, asking for just a "synthetic powder brush" is too vague. A PBT brush will give a soft, diffuse application, while a PET brush might be too stiff, leading to a poor user experience. Let’s break down the technical specs.

Fiber Material Comparison

Here is a simple table to help you compare the most common fiber options for your next brief.

| Fiber Type | Base Polymer | Best Use-Case | Key Properties | sustainability4 |

|---|---|---|---|---|

| PBT (Taklon5) | Polybutylene Terephthalate | Powder, Liquid, Cream | Excellent softness, good spring, great pickup/release | Virgin; recycled (rPBT) options are emerging. |

| PET | Polyethylene Terephthalate | Liquid, Cream; some applicators | Stiffer than PBT, good for structure | Virgin; recycled (rPET) is widely available. |

| nylon6 | Polyamide | Some applicators (e.g., mascara wands) | Good resilience, but can be less soft than PBT | Virgin; less common in recycled brush forms. |

| recycled fibers7 | rPBT / rPET | Powder, Liquid, Cream | Performance can match virgin if quality is high | Post-Consumer Recycled (PCR) content. |

| MCF | Engineered Polyester | Powder | Mimics natural hair cuticles for superior pickup | Virgin; premium price point. |

Nylon is the most popular material for premium powder brushes today.False

PBT (Taklon) has largely replaced nylon in premium face and eye brushes due to its superior softness and powder pickup performance.

PBT has a high melting point, making it resistant to damage from typical cleaning and drying.True

PBT's melting point is around 223°C, which provides a good safety margin for cleaning with solvents and gentle heat, preserving the fiber's shape.

What is Taklon, and why is it preferred?

You see the word "Taklon" everywhere, but what is it? Is it a specific material or just a marketing term? This confusion makes it hard to write a precise product brief.

In the brush industry, "Taklon" is a common name for high-quality synthetic filaments made from PBT polymer. It’s preferred because these fibers can be engineered with fine, tapered tips that mimic the softness and pickup of natural hair while being more durable and hygienic.

When a client asks me for a "Taklon" brush, I know they want a high-performance synthetic. But my job as a manufacturer is to dig deeper. The name itself doesn’t guarantee quality. The real performance comes from the engineering of the PBT fiber. Two "Taklon" brushes can feel completely different. One might be perfect for a sheer powder, and the other might be better for a cream foundation. It all depends on the specifications we define.

Beyond the Name: Fiber Engineering

Think of it this way: "Taklon" tells you the ingredient (PBT), but not the recipe. The recipe is in the engineering specs.

- fiber diameter8: This is measured in microns. Finer fibers (e.g., 0.05mm) create a much softer feel, ideal for finishing powders. Coarser fibers (e.g., 0.10mm) provide more spring and are better for blending dense creams. In my experience, blending different diameters in one brush head is a great way to achieve both softness and control.

- tapering9: This is the most important factor for powder pickup. A non-tapered fiber is like a straight stick. A tapered fiber is pointed, creating a much finer tip. This tapered geometry, along with micro-texturing on the fiber’s surface, creates more surface area to grab onto powder particles. When you write your brief, specifying a "finely tapered PBT" is much more precise than just asking for "Taklon."

Taklon is a type of natural animal hair.False

Taklon is a trade name for a synthetic fiber, typically made from PBT polyester. It is 100% vegan and cruelty-free.

The performance of a Taklon brush is determined by its fiber diameter and taper ratio.True

While the base material is PBT, the softness, spring, and powder pickup are controlled by engineering factors like how fine the fiber is (diameter) and how sharply it is pointed (taper).

Can recycled fibers (rPBT/rPET) match performance for brushes?

Your brand is committed to sustainability, but you’re worried about sacrificing quality. Using a recycled fiber that feels scratchy or doesn’t apply makeup well could disappoint customers and damage your brand.

Yes, high-quality recycled fibers can absolutely match the performance of virgin materials. Leading suppliers now produce 100% recycled PBT (rPBT) and PET (rPET) filaments that are engineered for softness and pickup. The key is to verify the source and test the samples.

I’ve seen the demand for sustainable materials grow incredibly fast. For brand founders like you, it’s a powerful story. But as a manufacturer, my focus is on ensuring the final product is perfect. One of the biggest pain points for brands is receiving a bulk order that doesn’t match the approved sample. This risk is even higher with new materials like recycled fibers if the factory doesn’t have strict quality control. That’s why my process is built on verification. We don’t just take a supplier’s word for it. We test everything.

Your Checklist for Sourcing Recycled Fibers

When you add recycled fibers to your brief, you need to be specific to protect your brand.

- Demand Traceability: Ask for certification of the recycled content. Is it Post-Consumer Recycled (PCR)? What percentage of the fiber is recycled? A reliable supplier should provide this documentation.

- Test for Performance Parity: Always get a sample made with the recycled fiber and compare it directly to a virgin fiber version. Check for softness, product pickup, and application. Don’t just feel it with your fingers; test it with your makeup formula.

- Check for Visual Consistency: Early recycled materials sometimes had issues with color uniformity or tiny impurities. Modern, high-quality rPBT/rPET has solved this, but it’s still something to check in your quality control process. Ensure the color is stable and won’t bleed after repeated cleanings.

Recycled brush fibers are always scratchier than virgin fibers.False

High-quality recycled PBT and PET fibers can be engineered with the same fine diameters and tapering as virgin fibers, achieving identical softness and performance.

You should request a Post-Consumer Recycled (PCR) content certificate when sourcing sustainable brushes.True

This documentation verifies the percentage of recycled material and its origin, ensuring your sustainability claims are accurate and traceable.

Are antimicrobial or infused fibers effective and safe?

You see brushes marketed as "antimicrobial" or "charcoal-infused" and wonder if it’s a real benefit or just a gimmick. Making a functional claim you can’t prove is a huge risk for your brand.

Infused fibers can be effective, but their performance and safety depend entirely on the additive and how it’s incorporated. You must get test reports from your manufacturer to substantiate any antimicrobial claims and ensure the materials comply with regulations in your market (like REACH or Prop 65).

This is an area where brand owners need to be extremely careful. One of the biggest pain points I hear from clients is dealing with factories that overpromise and under-deliver, especially when it comes to certifications and claims. A factory simply telling you a brush is "antimicrobial" is not enough. Without proof, that claim is a liability. As a partner in your brand’s success, I always insist on providing the right documentation.

How to Approach Infused Fibers Safely

If you want to explore this feature, here is what you need to do to protect your business.

- Understand the Mechanism: The most common additives are silver ions or activated charcoal. These are usually mixed into the polymer melt before the fiber is extruded. This helps ensure the agent is permanent and won’t wash out. Ask the supplier to explain the technology.

- Demand Substantiation: Do not launch the product without a third-party lab report. This report should identify the testing method (e.g., ISO 22196) and show a statistically significant reduction in microbial growth compared to a standard fiber. This is your proof.

- Verify Safety and Compliance: The additives themselves are chemicals. You must ensure they are safe for skin contact and comply with all regulations in the countries where you plan to sell. For example, materials sold in the EU must be REACH compliant, and those sold in California must be screened for Prop 65 chemicals. Your manufacturer should provide these material safety data sheets and compliance declarations.

Any brush with charcoal in it is automatically antimicrobial.False

While charcoal has absorptive properties, an 'antimicrobial' claim must be proven with specific lab testing that shows it inhibits or kills microorganisms. The presence of charcoal alone is not sufficient proof.

You need to verify that any additives in your brush fibers are compliant with regulations like REACH for the EU market.True

Chemical safety regulations like REACH and Prop 65 apply to all components of a product, including additives in brush fibers. It is the brand's responsibility to ensure compliance.

Conclusion

Choosing the right synthetic fiber means looking beyond marketing terms. Focus on the polymer (PBT, PET), the engineering (diameter, taper), and verifiable claims (recycled content, antimicrobial efficacy) for success.

References

-

Understanding synthetic fibers is crucial for selecting the right materials for high-performance makeup brushes. ↩

-

PBT is a popular choice for its softness and durability; learn why it’s preferred in premium brushes. ↩

-

Exploring PET’s properties can help you understand its role in brush design and performance. ↩

-

Sustainability is a growing concern; explore how to incorporate eco-friendly practices in your brand. ↩

-

Taklon is synonymous with quality in synthetic brushes; learn about its advantages and applications. ↩

-

Nylon has unique properties; knowing them can guide your choices in brush materials. ↩

-

Discover how recycled fibers can match performance and support sustainability in your products. ↩

-

Fiber diameter is key to brush feel and application; understanding it can enhance your product design. ↩

-

Tapering affects powder pickup; knowing its significance can improve your brush’s effectiveness. ↩