Sourcing brushes without knowing their parts can lead to quality issues and wasted money. I’ll show you how to specify a brush like a pro, ensuring quality from day one.

A makeup brush has three parts: the Bristles1 (head), the ferrule, and the handle. Bristles apply product, the ferrule is the metal sleeve securing them, and the handle provides balance. Understanding these components is key to sourcing high-performance, durable brushes for your brand.

When I first started on the factory floor, I was amazed at how these three simple parts could create such a huge difference in quality. A brush isn’t just a brush; it’s an engineered tool. Getting the specifications right for each part is the difference between a customer favorite and a product that sheds, breaks, or just doesn’t perform. For brand founders like you, knowing this anatomy is your first step toward controlling quality and building a product line you can be proud of. Let’s break down each part so you can talk to any factory with confidence.

All makeup brush handles are made from wood for a premium feel.Faux

Handles are also commonly made from plastic, resin, and bamboo, each offering different benefits in durability, cost, and sustainability.

The ferrule is the metal part that connects the bristles to the handle.Vrai

The ferrule's job is to hold the bristle knot securely and attach it to the handle, preventing shedding and wobbling.

What are the three main parts of a makeup brush, and what do they do?

Confused by industry terms like "belly," "toe," and "crimp"? This confusion can lead to costly miscommunications with suppliers. I’m here to make the language of brush making simple.

A makeup brush has bristles (the head), a Ferrule2 (the metal connector), and a handle (the grip). The bristles apply product, the ferrule holds them tight to prevent shedding, and the handle provides balance and control. This is the core vocabulary for sourcing.

Understanding the function of each part is crucial for creating a high-quality tool. When you send a tech pack to a manufacturer, using the right terms ensures your sample comes back exactly as you envisioned. Let’s look at each part and its "sub-parts" in more detail.

Bristles / Head

This is the working end of the brush. It’s not just a bundle of fibers; its shape is engineered for a specific task.

- Toe/Point: The very tip of the bristles, which determines the precision of the application.

- Belly: The fullest, widest part of the head. It holds the most product and is used for blending and pressing.

- Heel: The base of the bristles where they are bundled and glued together inside the ferrule. The integrity of the heel is critical for preventing shedding.

Ferrule

This is the metal sleeve that is the unsung hero of a quality brush. Its main job is to connect the head to the Handle3. It’s crimped, or indented, to physically grip the handle and the bristle knot, creating a secure, wobble-free connection.

Handle

The handle provides the grip, balance, and leverage for the user. Its material, weight, and finish contribute significantly to the brush’s overall feel and your brand’s identity. A well-balanced handle makes application effortless for the end-user.

The 'heel' of a brush refers to the tip of the bristles.Faux

The heel is the base of the bristles where they are glued together inside the ferrule. The tip is called the 'toe' or 'point'.

The 'crimp' is the indentation on the ferrule that secures it to the handle.Vrai

Crimping is a manufacturing step that physically presses the metal ferrule onto the handle, creating a strong mechanical bond.

Which bristle materials are best for powders vs liquids, and why do B2B buyers choose synthetic today?

Choosing the wrong bristle can make a great formula perform poorly, leading to bad reviews. This choice directly impacts customer satisfaction. I’ll help you match the right fiber to your product.

Natural Hair4 is great for powders, while synthetic fibers are best for liquids and creams. Today, most B2B buyers choose premium synthetics because they are vegan, cruelty-free, easier to clean, and offer consistent quality and stable costs for global retail compliance.

The debate between natural and synthetic bristles has changed a lot over the years. When I started, natural hair was seen as the only option for luxury. Now, technology has advanced so much that high-performance synthetics can mimic the best qualities of natural hair, without the ethical and logistical downsides. For a brand founder, this is great news. It means you can deliver performance and align with modern consumer values.

Natural vs. Synthetic: The Classic Choice

Here’s a quick breakdown of the traditional view:

| Bristle Type | Best For | Why? |

|---|---|---|

| Natural Hair | Powders (blush, eyeshadow) | Has a cuticle structure that grabs and diffuses powder pigments beautifully. |

| Synthetic Fibers5 | Liquids & Creams | Non-porous, so they don’t absorb product. This means less waste and a smoother application. |

Why "Spec the Knot" is a Game-Changer

Simply asking for "synthetic bristles" isn’t enough. The top brands I work with specify the details of the bristle knot to control performance. This is how you guarantee softness and pickup. Ask your supplier for:

- Fiber Family: PBT is a common high-performance choice.

- Tip Finish: Tapered tips feel softer and mimic natural hair.

- Filament Diameter (Dtex/μm): Thinner filaments create a softer, denser brush head.

- Knot Weight6 (grams): This determines the overall density of the brush.

Specifying these four variables explains 70-80% of the perceived quality difference between brushes.

Synthetic bristles are always cheaper than natural hair.Faux

While basic synthetics are cost-effective, high-performance, custom-engineered synthetic fibers can be as expensive as or more expensive than some common natural hairs.

PBT is a type of high-performance synthetic fiber used in makeup brushes.Vrai

Polybutylene terephthalate (PBT) is a popular choice for premium synthetic bristles due to its softness, durability, and ability to be finely tapered.

What ferrule materials and constructions reduce shedding and corrosion in real-world use?

Is your brush shedding after a few washes? The ferrule is likely the problem. A weak ferrule cheapens your product and ruins your brand’s reputation for quality. Let’s fix that.

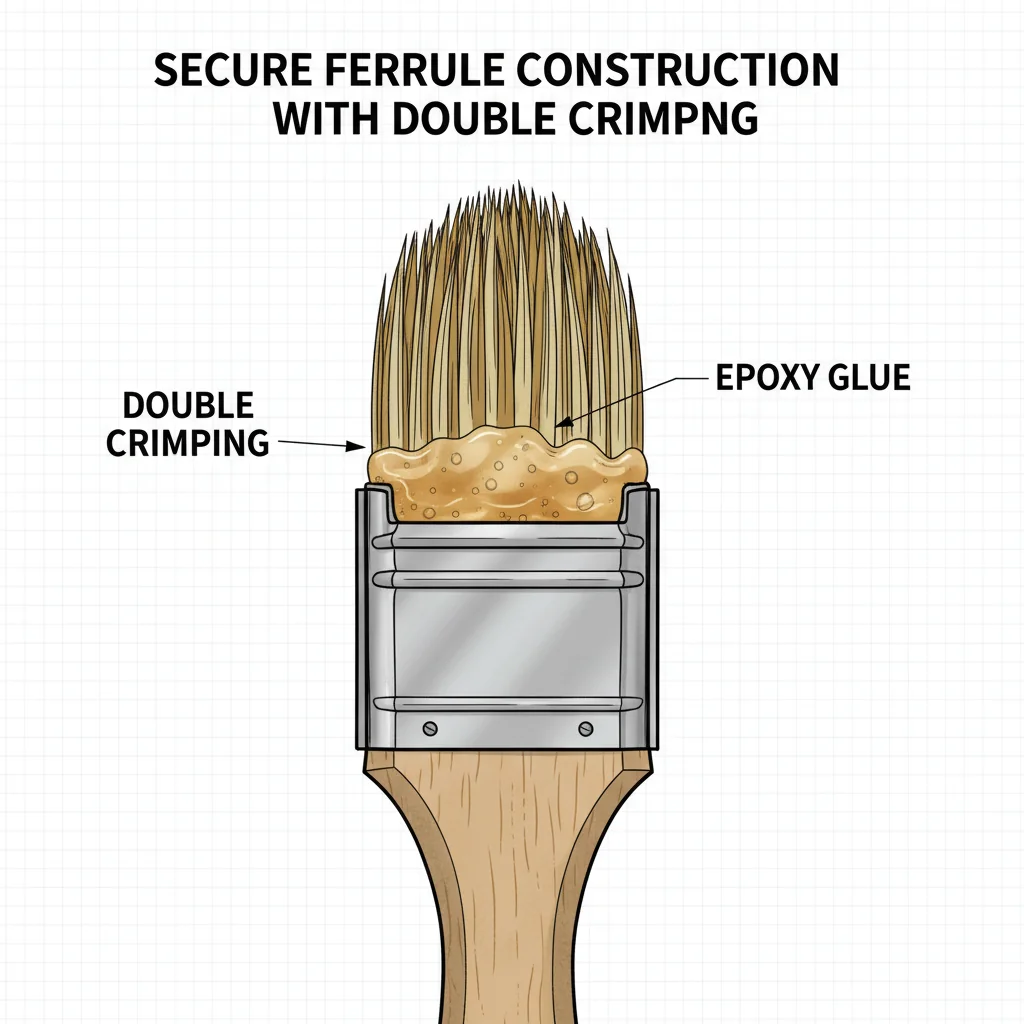

For minimal shedding and corrosion, choose a nickel-plated brass or stainless steel ferrule. Ensure it is constructed with a thick wall, double crimping, and a High-Solids Epoxy7 to securely lock the bristle knot. Aluminum is a budget option but less durable.

The ferrule is the structural core of the brush. I’ve seen so many brands try to cut costs here, only to face customer complaints about shedding and wobbly handles later. A few cents saved on the ferrule can cost you dollars in returns and brand damage. Investing in a better ferrule is one of the smartest cost-performance decisions you can make. For many mid-tier retail brands, upgrading from standard aluminum to a nickel-plated brass ferrule delivers a huge boost in perceived quality for a very small increase in cost.

Ferrule Materials: A Cost vs. Performance Breakdown

| Material | Pros | Cons | Best For |

|---|---|---|---|

| Aluminum | Lightweight, low cost | Soft, easily dented, can corrode | Entry-level or disposable brushes |

| Nickel-Plated Brass | Rigid, corrosion-resistant, premium feel | Heavier, higher cost than aluminum | Mid-tier to luxury retail brushes |

| Stainless Steel | Highest durability, waterproof | Highest cost, heaviest | Professional artist kits, wet-use brushes |

The Secrets to a Shed-Proof Brush

To stop shedding at the source, you need to specify the construction, not just the material. Here’s what to ask for:

- Two-Stage Bonding: The bristle knot should be deep-set in a high-solids epoxy, with a top seal to prevent any fibers from pulling loose.

- Double Crimp8: The ferrule should be crimped in two places to create a super-secure mechanical lock onto the handle.

- Quality Control Tests9: Ask your factory to perform a 100-stroke dry brush test and a three-cycle wash test. The standard for a quality brush is less than one hair lost per 100 strokes.

A double-crimped ferrule is more likely to shed than a single-crimped one.Faux

Double crimping provides a much stronger mechanical bond between the ferrule and the handle, significantly reducing wobble and the risk of the head detaching.

Brass is more corrosion-resistant than aluminum, making it a better choice for brushes that are washed frequently.Vrai

Brass, especially when plated with nickel, offers superior resistance to rust and corrosion compared to raw aluminum, increasing the brush's longevity.

How do handle materials and coatings impact durability, weight, and brand feel?

A handle that cracks, chips, or feels unbalanced makes your whole product feel cheap. This undermines your brand’s premium positioning. I’ll show you how to create a handle that lasts.

Wood offers a premium feel but needs proper sealing to prevent cracking. Resin and plastic are moisture-stable and great for custom colors. The handle’s coating (like PU or UV) determines its chip resistance, while its weight distribution affects user control.

The handle is your customer’s first physical touchpoint with your brand. It has to feel good in their hand. But it also has to be durable, especially for customers in humid climates. I’ve had clients who sourced beautiful wooden-handled brushes that started cracking and peeling within months because the factory didn’t control for moisture. Getting the material and the finish right is non-negotiable for building a lasting brand.

Handle Materials: More Than Just a Grip

- Wood (e.g., Birch, Ash): Provides a classic, weighty, and premium feel. It’s essential to use FSC-certified wood for sustainability claims and to demand proper sealing.

- Resin/Plastic (e.g., ABS, AS): Excellent for moisture stability, precise color matching, and creating unique shapes. Lighter than wood.

- Bamboo: A great choice for signaling sustainability. It’s lightweight and strong but requires proper finishing to maintain its stability over time.

The Importance of Finishing and Balance

The finish protects the handle and defines its feel.

- Coatings: A multi-layer PU or UV coating provides hardness and chip resistance. For a quality handle, you should specify a coating hardness of ≥2H (using the pencil hardness test).

- Humidity Testing: If you choose wood handles, especially for humid markets, require your supplier to perform a humidity test (e.g., 48 hours at 40°C/95% RH) to ensure the finish doesn’t crack or peel.

- Balance: A well-made brush should have its center of gravity near where the ferrule meets the handle. This provides better control for the artist or user.

Your Sourcing Checklist: From Anatomy to Action

Knowing the parts is the first step. Now, use this checklist to specify your next brush order like an expert. This turns your knowledge into a clear request for any manufacturer.

| Component | Specification to Request | Why It Matters |

|---|---|---|

| Bristles/Head | Fiber Type (e.g., PBT Synthetic), Tip Finish (Tapered), Filament Diameter (μm), Knot Weight (g) | Controls softness, density, product pickup, and application performance. |

| Ferrule | Material (e.g., Nickel-Plated Brass), Wall Thickness (mm), Construction (Double Crimp) | Determines durability, corrosion resistance, and prevents shedding/wobble. |

| Adhesive | Glue Type (e.g., High-Solids Epoxy), Bonding Process (Two-Stage) | Creates a powerful bond that locks bristles into the ferrule, eliminating shedding. |

| Handle | Material (e.g., FSC Wood, Resin), Finish (e.g., 5-Layer PU), Coating Hardness (≥2H) | Ensures durability, brand feel, and resistance to chipping and moisture damage. |

| QC Tests | Moisture/Humidity Test (for wood), Crosshatch Adhesion Test (for finish), 100-Stroke Shed Test | Verifies the final product will withstand real-world use and environmental conditions. |

Frequently Asked Questions

What is a ferrule on a makeup brush?

The ferrule is the metal tube that joins the bristles to the handle. It’s crimped and glued to compress the bristle knot and prevent shedding and wobble. It’s commonly made of aluminum or brass.

Are synthetic bristles better than natural?

Neither is universally "better." Natural hair is often preferred for powders, while synthetic is superior for liquids, easier to sanitize, and vegan. High-grade synthetics now rival natural hair in performance.

What are the minor parts called on the brush head?

The "belly" is the fullest section that presses product, the "toe" is the tip that affects precision, and the "heel" is where fibers enter the ferrule. These terms help define a brush’s shape and function.

What materials are common for handles?

Wood, resin/plastic, and bamboo are most common. Wood offers a premium feel but needs sealing. Resin is stable and great for colors. Bamboo is used for its sustainable positioning. The finish is key to durability.

Conclusion

Understanding the bristles, ferrule, and handle helps you source better brushes. Specify the right materials, construction, and finishes to create high-performance tools that build your brand’s reputation for quality.

Références

-

Explore the various bristle types to understand their impact on makeup application and product performance. ↩

-

Learn about the ferrule’s role in brush construction and how it affects durability and performance. ↩

-

Discover the best materials for brush handles to enhance user experience and brand identity. ↩

-

Understand why natural hair is favored for certain applications and its unique properties. ↩

-

Find out the advantages of synthetic fibers, including ethical considerations and performance. ↩

-

Discover how knot weight influences the density and application of makeup brushes. ↩

-

Explore the importance of high-solids epoxy in ensuring a strong bond in brush construction. ↩

-

Learn how double crimping enhances the durability and performance of makeup brushes. ↩

-

Learn about essential quality control tests to ensure the performance and durability of makeup brushes. ↩