You admire the NARS #16 blush brush, but its public specs are vague. This makes it hard to create your own version. I will show you the hidden details.

The NARS #16 Blush Brush uses synthetic, hypoallergenic fibers in a domed shape for sheer-to-medium coverage with powder and cream. To replicate it, you must specify tapered PBT fibers1, a stable ferrule crimp, low-shed adhesive, and QC tests that verify performance.

You see a successful product on the shelf and want to create something similar for your own brand. But the real magic is in the details that brands don’t publish. I learned this firsthand on the factory floor, watching how tiny changes in materials or process could make or break a brush. It’s not just about copying a shape. It’s about understanding the engineering behind the performance. Let’s break down what really matters, so you can build a brush that’s not just inspired by the best, but is built for your brand’s specific needs.

The NARS #16 Blush Brush is made from natural goat hair.Faux

NARS officially states the current #16 brush uses durable synthetic fibers. While older or different NARS brushes may have used animal hair, this specific SKU is marketed as synthetic and hypoallergenic.

The NARS brand is not certified cruelty-free.Vrai

NARS sells its products in physical stores in mainland China, where animal testing can be required by law for imported cosmetics. Therefore, it does not meet the criteria for certifications like Leaping Bunny.

What Materials Make the NARS #16 Brush Work, and How Can You Improve Them?

NARS says its brush uses “durable synthetic fibers2.” This tells you almost nothing. Building your brand on vague terms is a risk. I will show you what to specify.

The brush likely uses Polybutylene Terephthalate (PBT) fibers. For your own brush, you should specify tapered, heat-treated tips and a mix of fiber thicknesses (deniers) to perfect pickup and blending for both powder and cream formulas.

Deconstructing "Synthetic": From PBT to Tapering

When a factory hears "synthetic," they could use several materials. You need to be specific. I always guide my clients to use PBT for high-end blush brushes. It is softer than other options like Nylon and performs much better with cream products because it doesn’t clump. The real secret is in the fiber design. We use a bimodal denier distribution. This means we mix very fine fibers with slightly thicker ones. The fine fibers pick up pigment beautifully. The thicker fibers provide structure, or what we call "backbone," so the brush doesn’t feel flimsy. We also specify heat-treated, tapered tips. This process makes the fiber ends extra soft and flexible, which is key for diffusing color without any harsh lines. This level of detail is how you create a truly premium brush and confidently make claims like "hypoallergenic" or "vegan."

| Fiber Type | Best For | Feel & Performance |

|---|---|---|

| PBT | Powder & Cream | Very soft, excellent pickup, resists clumping. |

| Nylon | Powder | Stiffer, durable, good for dense packing. |

| Taklon | Powder & Liquid | General-purpose, good baseline synthetic. |

| PET | Budget Brushes | Coarser, less soft, not ideal for face brushes. |

All synthetic brush fibers offer the same performance.Faux

Different synthetic polymers like PBT, Nylon, and PET have distinct properties affecting softness, durability, and how they interact with cream versus powder products. PBT is generally preferred for its softness and performance with creams.

Tapering the tips of synthetic fibers improves their blending ability.Vrai

Tapering creates a finer, more flexible point on each bristle. This allows the brush to diffuse makeup more smoothly across the skin, reducing the chance of streaks or harsh lines.

How Does the Domed Shape Affect Performance, and What Tests Prove It?

A domed brush is a classic for blush, but how it performs is not an accident. Guessing how it will work with your new cream blush is not a business strategy.

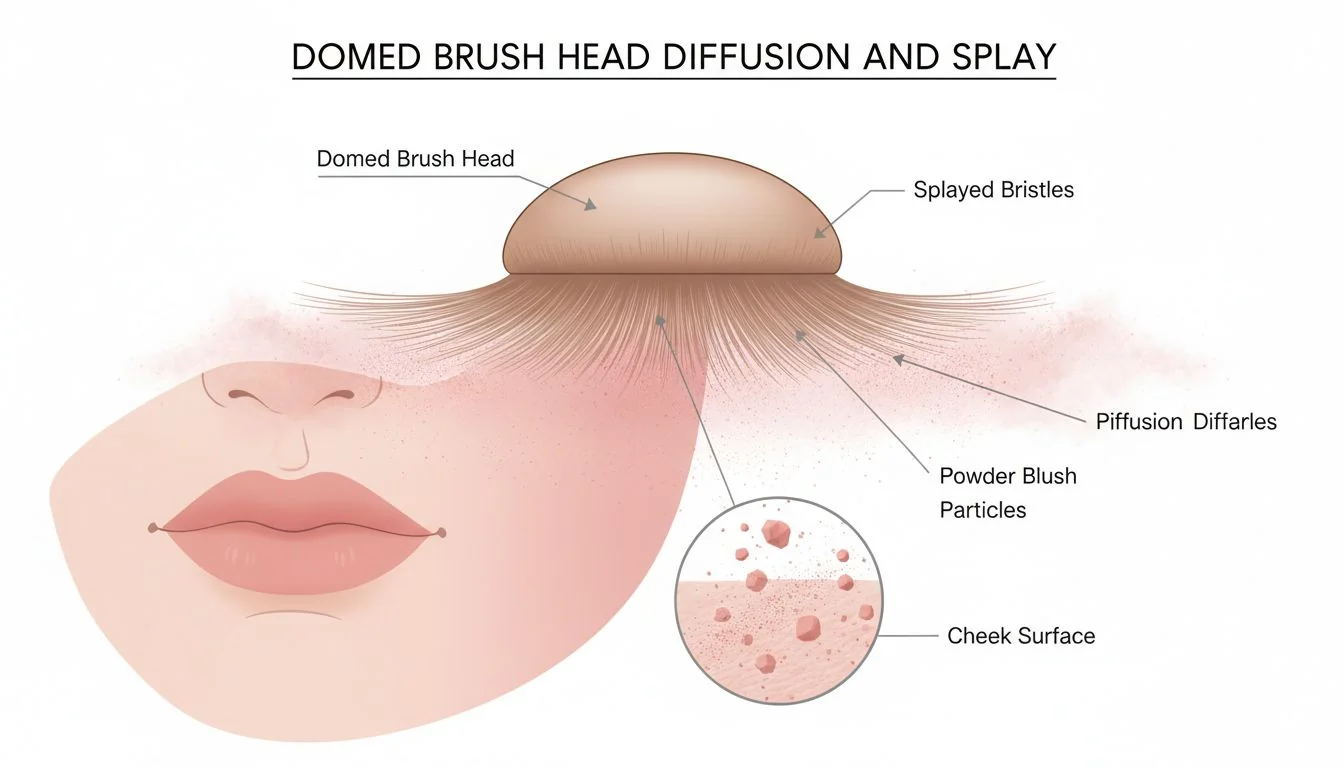

Le domed shape3 is designed to diffuse pigment for a soft-focus look. You can prove its performance by measuring powder pickup percentage, cream blending uniformity, and the splay radius under a defined force. These tests give you real data.

From Shape to Science: Key Performance Metrics

The domed head is popular because it has no sharp edges. This allows it to apply color and blend at the same time. But the quality of that blend depends on factors you can control and measure. When I work with brand founders like Emily, we move beyond just looks and into performance testing4. We establish key metrics to ensure every brush in the batch performs perfectly. For a blush brush, we measure the Powder Pickup Percentage to ensure it doesn’t waste product. We test Cream Blending Uniformity on a standard surface to see if it creates patches. We also measure the Splay Radius by applying a specific force (e.g., 50 grams) to see how the bristles fan out. This tells us how it will feel and perform on the cheek. These numbers become part of your quality control plan, protecting your brand from inconsistency.

| Test Metric | What It Measures | Why It Matters for a Blush Brush |

|---|---|---|

| Shed Rate | Bristles lost per 100 strokes | Ensures durability and prevents customer complaints. |

| Splay Radius | How bristles fan out under pressure | Predicts how softly the brush will diffuse color. |

| Recovery Test | Shape retention after washing | Guarantees the brush maintains its performance over time. |

| Pickup % | Amount of powder lifted | Balances product application with preventing waste. |

The density of a brush does not affect its performance.Faux

Brush density is critical. A less dense brush provides a sheer, diffused application, while a denser brush packs on more pigment for intense color payoff. The density must match the intended use.

A domed brush shape is designed to prevent harsh lines during blush application.Vrai

The rounded, graduated shape of a domed brush head naturally softens the edges of the application area, making it easier to blend and diffuse pigment for a seamless finish.

What Are the 15 OEM Steps to a Perfect Brush, and Where Do Failures Happen?

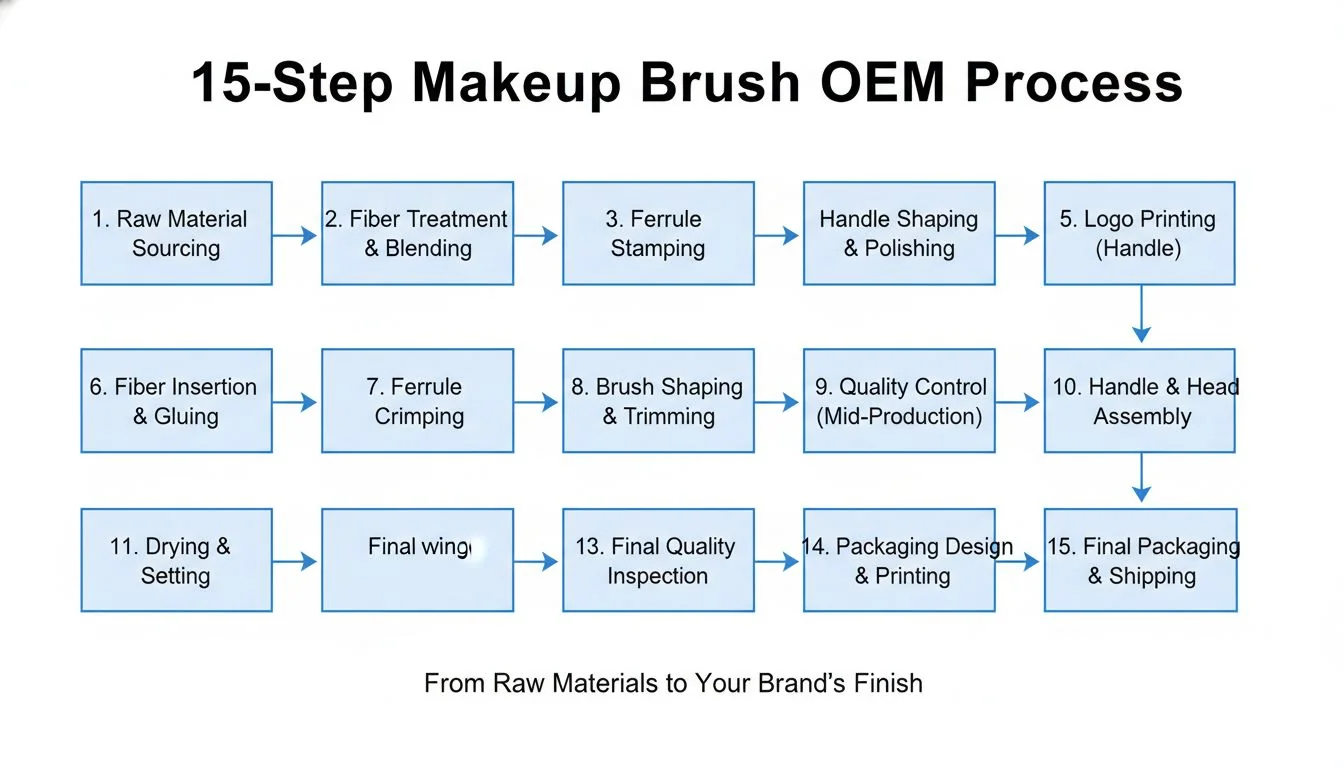

You approved a perfect sample, but the bulk order has shedding bristles and loose heads. The problem is hidden in the manufacturing process. I will show you exactly where to look.

A quality brush goes through about 15 steps, from weighing bristles to final cleaning. Shedding and loose heads are usually caused by failures in adhesive setting, ferrule crimping, or poor final QC. Strict tolerances at these stages are non-negotiable.

The Factory Floor: A Quality Checklist

I’ve seen it all. A beautiful brush can fail because of one rushed step. The most critical points are the ones you can’t see. First is the adhesive. We use a solvent-based epoxy resin because it creates the strongest bond, preventing shedding. We specify the exact curing time and temperature and then perform a "pull-off strength" test on random samples to verify the bond. Second is the ferrule. We use anodized aluminum (grade 6063) at 0.3–0.4 mm thickness. This provides the perfect balance of strength and weight. The crimping process, which secures the ferrule to the handle, must be precise. A bad crimp is the number one cause of a wobbly, loose head. Finally, QC is not just one step. We inspect raw materials, check bundles during assembly, and test finished brushes for shed rate and durability. This is how you stop problems before they start.

Key Manufacturing Checkpoints:

- Bristle Weighing & Bundling: Ensures consistent density.

- adhesive application5 & Curing: Critical for preventing shedding.

- Ferrule Crimping: Secures the head to the handle.

- Handle Finishing: Ensures a smooth, durable coating.

- Final Performance QC: Includes shed tests and pull tests.

Brass ferrules are always superior to aluminum ferrules.Faux

While brass is heavier and can provide a strong crimp, high-grade anodized aluminum offers excellent corrosion resistance and crimp stability at a lower weight. The choice depends on the desired brush balance and cost.

A 'pull-off strength' test is a standard QC measure to check for loose brush heads.Vrai

This test applies a measured force to the brush head to ensure the adhesive and ferrule crimp can withstand regular use without the head detaching from the handle.

How Do You Navigate Ethics, Compliance, and ‘Cruelty-Free’ Claims for Your Brand?

Your customers want safe, ethical products. But regulations are complex and a mistake can ruin your brand’s reputation. Let’s make it simple and safe for you.

NARS is not cruelty-free6 because it sells where animal testing is required by law. For your brand, use synthetic fibers and demand documentation for REACH (EU) and CPSIA (US) compliance. This allows you to make your claims with confidence.

Your Brand’s Integrity: Documentation and Claims

This is one of the biggest pain points I see with new brand founders. You can’t just say your product is "vegan" or "safe for Europe." You have to prove it. The NARS situation is a perfect example. They use synthetic fibers for the #16 brush, but the brand itself isn’t cruelty-free because of its sales policies in certain countries. For your brand, the path is clear. First, commit to 100% synthetic, vegan fibers. Second, your factory must provide the paperwork. For selling in the EU, you need REACH compliance reports for the chemicals in your adhesives and handle coatings. For the US, you need CPSIA reports to prove the coatings are free of lead and phthalates. I make sure every Brushino client gets a full documentation package. This protects your business, builds trust with your customers, and gives you the power to market your products ethically and honestly.

Essential Documentation Checklist:

- Material Safety Data Sheet (MSDS): For all raw materials, including fibers and adhesives.

- REACH compliance7 Certificate: For products sold in the European Union.

- CPSIA Test Report: For products sold in the United States, especially for children’s items.

- Vegan & Cruelty-Free Affidavits: A signed statement from the factory confirming no animal products or testing were used.

A 'vegan' brush can still be made by a brand that is not cruelty-free.Vrai

A 'vegan' product contains no animal-derived ingredients. However, the brand that sells it may still test other products or ingredients on animals, making the brand itself not cruelty-free.

REACH is a European Union regulation concerning the safety of chemical substances.Vrai

REACH stands for Registration, Evaluation, Authorisation and Restriction of Chemicals. It requires companies to identify and manage the risks linked to the substances they manufacture and market in the EU.

Conclusion

Replicating a great brush requires more than copying its shape. It demands precise specs, performance testing, and a transparent manufacturing process. With the right knowledge, your brand can create superior tools.

Références

-

Learn about PBT fibers to enhance the quality and performance of your makeup brushes. ↩

-

Understanding the advantages of synthetic fibers can help you choose the best materials for your brush. ↩

-

Discover how the design of a brush influences its effectiveness in applying makeup. ↩

-

Learn about performance testing to ensure your brushes deliver the best results. ↩

-

Choosing the right adhesive is crucial for the durability and performance of your brushes. ↩

-

Understanding cruelty-free standards can help you market your brand ethically. ↩

-

Learn about REACH compliance to ensure your products meet safety regulations in the EU. ↩