Creating a compact, travel-friendly brush sounds great, but the process feels complex. Mistakes in design or compliance can delay your launch and hurt your brand. Here is a clear path.

A 4-in-1 brush1 goes through four phases: design brief (choose four heads, retractable mechanism, materials), sampling (≈2 weeks), compliance and QC (ISO 9001, REACH, ferrule/glue tests), and mass production (≈60–75 days OEM; ≈6–10 weeks ODM). Align tolerances, cycle-test retractables to ≥5,000 uses, and finalize packaging before SOP.

I’ve seen so many brand founders like you, Emily, get excited about a multifunctional tool. It’s a fantastic idea for today’s on-the-go customer. But I’ve also seen the frustration when the final product feels wobbly, sheds, or fails to meet retail standards in the US or EU. The secret isn’t just a good idea; it’s a solid manufacturing plan.

From my days on the factory floor to running Brushino, I’ve learned that every successful product starts with a clear, detailed plan. This is especially true for a complex item like a 4-in-1 brush. Let’s walk through the exact steps we use to take this concept from a simple drawing to a shelf-ready product, so you can avoid the common pitfalls.

A typical OEM makeup brush sample can be produced and shipped in 3 days.Faux

While simple modifications might be quick, a new custom OEM sample requires tooling adjustments, material sourcing, and assembly, which realistically takes about 2 weeks.

The choice of the four brush heads directly impacts the engineering of the handle and retractable mechanism.Vrai

The size, shape, and weight of each head dictate the ferrule geometry, retention mechanism, and internal tolerances needed to ensure a secure fit and smooth function.

How do you lock the 4 heads, ergonomics, and tolerances in just 2 weeks?

Your great idea for a 4-in-1 brush is just a starting point. Without a detailed technical brief, factories often produce inaccurate samples, wasting your time and money. A professional Design for Manufacturing (DFM) process solves this.

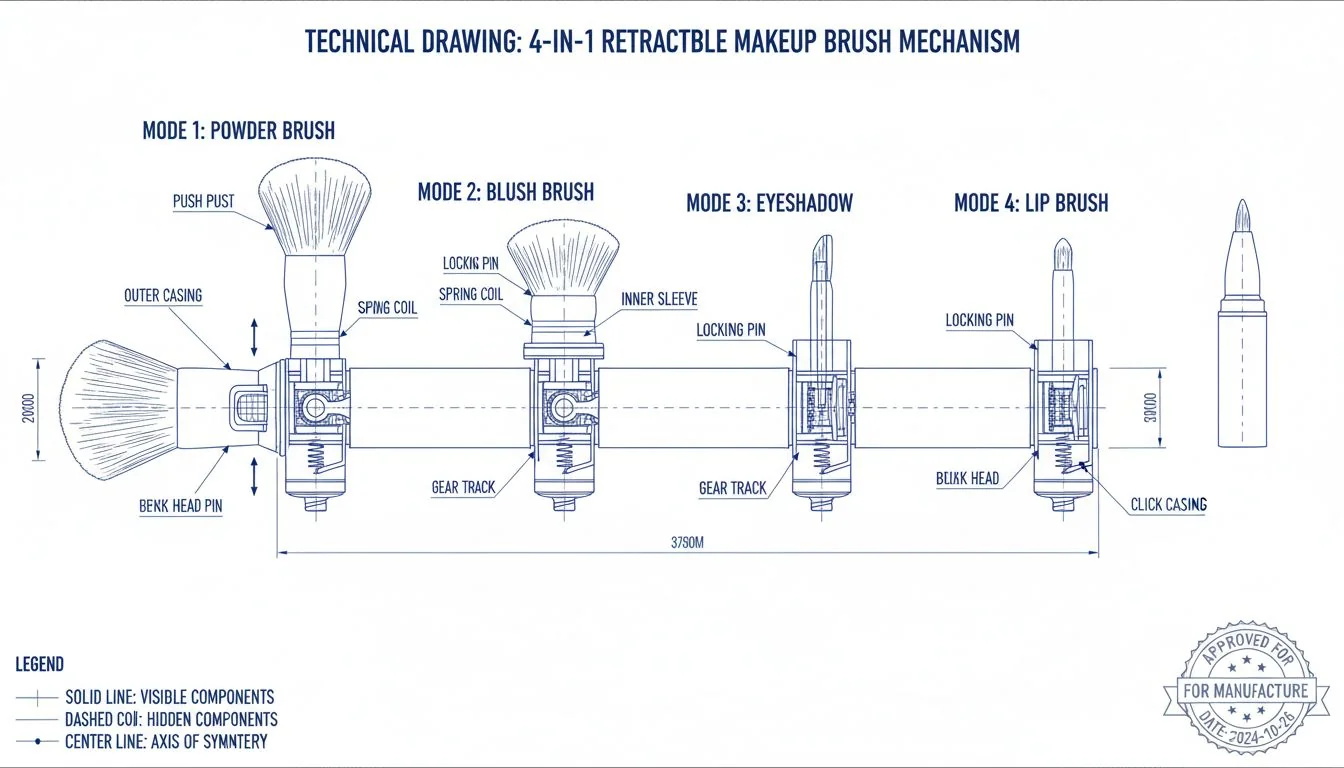

To get an accurate sample in about two weeks, you must first define the four heads and the core mechanism. Then, provide your OEM partner with detailed drawings covering ferrule geometry, material specs, and tolerances.

The first conversation I have with a client about a new brush always starts with function. Before we talk about colors or logos, we have to decide what the brush will do. This decision drives all the engineering that follows. A vague brief like "a 4-in-1 travel brush" isn’t enough. We need to get specific.

Defining the Four Functions First

The user journey determines the design. Are you creating a kit for a full face? Then you might need a powder head, a smaller highlighter head, an eyeshadow shader, and a lip brush. This combination dictates the size of each ferrule, the density of the bristles, and the overall balance of the handle. The mechanism—whether it’s retractable or telescopic—must be designed to accommodate the largest and smallest heads without wobbling. I always tell my clients to think about the end-user first. What four tools do they need most when traveling?

Creating a DFM-Ready Tech Pack

Once the functions are set, we translate them into a technical package. This isn’t just a sketch; it’s a blueprint for the factory. It includes:

- Component Drawings: Detailed diagrams of the handle, ferrules, and internal core, with precise tolerances (e.g., +/- 0.05mm) to ensure a snug fit.

- Hair Specification: The type of fiber (like PBT or Taklon), length, density, and cut.

- Material Callouts: Specifying ABS for the handle, aluminum for the ferrules, and the exact type of adhesive.

With this level of detail, we can move to sampling with confidence.

| Development Path | Sampling Time | mass production lead time2 | Best For |

|---|---|---|---|

| OEM | ≈ 2 weeks | ≈ 60–75 days | Unique designs, custom mechanisms |

| ODM | ≈ 1–3 weeks | ≈ 6–10 weeks | Speed, budget, adapting existing tools |

All synthetic brush fibers are the same.Faux

Fibers like PBT and Taklon come in many grades, affecting softness, pickup, and durability. The quality of the fiber is a key cost and performance driver.

A detailed tech pack can reduce sampling errors by over 50%.Vrai

Clear specifications for dimensions, materials, and tolerances eliminate guesswork for the factory, leading to more accurate first-time samples and faster development.

How do you ensure REACH-safe fibers, FSC handles, and low-VOC adhesives?

You want to sell your brush in major markets like the US and EU. But using non-compliant materials can lead to your products being pulled from shelves, resulting in huge losses. The solution is to build compliance into your material selection from day one.

Map every single component of your brush to the required standards, such as ISO 90013 for quality management, REACH for chemicals, and FSC for wood. You must request and verify all compliance documents before you approve any pre-production samples.

I remember a client who was ready to launch a beautiful brush set. But during final checks, we found the adhesive used by their previous supplier had high levels of Volatile Organic Compounds (VOCs). They had to rework the entire order, which delayed their launch by two months. This is a costly mistake that is easy to avoid if you anchor your decisions in compliance early. We create a "Compliance Map" for every project.

Mapping Your Bill of Materials (BOM) to Standards

This process is straightforward. We list every part of the brush and assign the necessary standard or test to it. This becomes part of our quality control plan and ensures nothing is missed. It’s a simple checklist that provides total peace of mind.

| Component | Material Example | Standard/Test Required for US/EU Market |

|---|---|---|

| Bristles | PBT/Taklon | REACH (chemical safety), Microbiology |

| Handle | Wood / Bamboo | FSC (Forest Stewardship Council) |

| Ferrule | Aluminum/Brass | RoHS (heavy metals), Nickel-release |

| Adhesive/Glue | Epoxy Resin | VOC Test, Heavy Metals Test |

| Printing/Paint | Ink/Coating | REACH, Heavy Metals (Pb, Cd) |

This map acts as our guide. Before we even start mass production, we gather all the certificates from our material suppliers. This documentation is not just for our records; it’s for you and your retailers. It proves your product is safe, high-quality, and ready for the global market.

FSC certification only applies to the wood itself, not the final product.Faux

FSC certification requires a 'chain of custody' to be maintained. The factory assembling the brush must also be FSC-certified to apply the FSC label to the final product.

REACH is a European Union regulation concerning the Registration, Evaluation, Authorisation and restriction of Chemicals.Vrai

It is a critical compliance framework for any product sold in the EU, ensuring that substances used are safe for human health and the environment.

How do you create retractable mechanisms that survive 5,000 cycles?

A 4-in-1 brush has moving parts, and moving parts can fail. A customer might forgive a lot, but a wobbly, shedding, or broken brush will destroy their trust in your brand. You can prevent this by specifying and verifying reliability with tough, real-world tests.

In your tech pack, you must define clear reliability targets. This includes wear-cycle tests for any retractable or telescopic parts (we test for at least 5,000 actuations), retention torque tests for the heads, and a hair fallout rate4 of less than 1%.

This is where my experience on the factory floor becomes so important. I’ve seen firsthand what separates a premium brush from a cheap one, and it often comes down to the things you can’t see, like the internal mechanism and the way the hairs are secured. A wobbly ferrule is an instant sign of poor quality.

Specifying Mechanical Tests

We don’t just hope for the best; we test for failure. For a 4-in-1 brush, our standard testing protocol includes:

- Cycle Test: We use a machine to open and close the retractable mechanism5 5,000 times. It must function smoothly from the first cycle to the last.

- Torque Test: We measure the force required to twist a brush head off. It has to be secure enough for vigorous use but still allow for easy swapping.

- Fallout Test: We use a machine to comb the brush head a set number of times and count how many bristles fall out. Our target is always under 1% fallout for incoming materials.

- Drop Test: We drop the assembled brush from a height of 1 meter onto a hard surface from multiple angles to simulate real-world accidents.

The Importance of Craftsmanship

Testing is critical, but so is the initial craft. We follow the practice of using uncut hair tips, a technique perfected by Japanese brands like Hakuhodo. Even with synthetic PBT fibers, keeping the natural tapered tip makes the brush feel softer and perform better. It prevents that scratchy feeling you get from cheap brushes where the fibers are bundled and bluntly cut. This attention to detail is what creates a tool your customers will love and use for years.

A 1-meter drop test is the industry standard for all cosmetic components.Faux

While a 1-meter drop test is common for durable items like brushes, more fragile components like glass bottles or pressed powders are often tested at lower heights (e.g., 76 cm).

Using uncut, tapered bristle tips improves makeup application by providing a softer feel and better product pickup.Vrai

Blunt-cut bristles can feel scratchy and don't pick up or blend product as smoothly as fibers with their original tapered ends intact.

How do you get from EVT samples to a 75-day mass production?

You’ve finally approved the perfect sample. That’s great, but what happens next? The journey to mass production is filled with potential delays if not managed correctly. The key is to use a staged-gate process to control quality and keep to your timeline.

Follow a clear sampling and production path: EVT for fit and feel, DVT for reliability, and PVT for packaging and final assembly. This structured approach ensures a smooth transition into mass production, aligning with a typical 60–75 day OEM lead time.

The biggest fear for any brand founder is a delay that causes them to miss a seasonal launch or a big marketing campaign. A structured production timeline isn’t just about being organized; it’s about protecting your business. We break the process down into clear stages, with approval required at each gate before moving to the next. This prevents surprises and keeps everyone accountable.

Understanding the Sampling Gates (EVT, DVT, PVT)

This process, borrowed from the electronics industry, is perfect for complex products like a 4-in-1 brush.

- EVT (Engineering Validation Test): This is your first sample. The goal is to check the basic design, fit, and feel. Does it match the drawings? Does the handle feel good in your hand?

- DVT (Design Validation Test): Now we test for durability. This is where we perform the cycle tests, drop tests, and hair fallout tests. We are confirming that the design is robust enough for real-world use.

- PVT (Production Validation Test): This is the final pre-production run. We use the actual tooling and processes for mass production to make a small batch. We check everything, including the final packaging, logo printing durability, and assembly efficiency.

Once PVT is approved, we hold a final meeting and officially begin the Start of Production (SOP).

| Metric | OEM (Custom) | ODM (Catalog) |

|---|---|---|

| Production Time | 60–75 days | 6–10 weeks |

| Typical MOQ | 1,000–3,000 units | 100–500 units |

| Unit Cost Example | >$2 (depends on complexity) | <$2 (for simple builds) |

PVT samples are handmade in a lab.Faux

PVT (Production Validation Test) samples are made on the actual production line using the final tooling and processes to ensure the product can be manufactured consistently at scale.

ODM is always cheaper than OEM.Vrai

ODM (Original Design Manufacturing) uses existing molds and designs, eliminating the significant upfront tooling and R&D costs associated with a fully custom OEM (Original Equipment Manufacturer) project.

Your Top Questions Answered

What’s the realistic timeline from design to delivery?

For a custom OEM brush, expect about 2 weeks for samples. Once you approve the final sample, mass production and shipping typically take 60–75 days. If you adapt an existing ODM design, the entire process can be faster, around 6–10 weeks.

Which materials suit a 4-in-1 travel brush?

I recommend vegan PBT/Taklon fibers6 because they are versatile and easy to clean. For the ferrules, aluminum or brass provide good durability and a secure grip. Handles can be ABS/PP plastic for a lightweight feel or FSC-certified wood for a more premium touch. Always use adhesives with low VOCs for safety.

How do I ensure zero wobble and minimal hair fallout?

This comes down to three things: tight engineering tolerances for the ferrules, specifying the right glue viscosity, and rigorous testing. We cycle-test retractable parts for at least 5,000 uses and use the uncut hair tip assembly method to lock bristles in place and preserve performance.

What compliance do I need for US/EU retail?

To sell confidently, ensure your manufacturer operates under an ISO 9001 quality system. You’ll need documentation for REACH (chemicals), heavy metals (like Nickel, Lead, Cadmium), and VOCs. If you use wood, get FSC certification7. This protects your brand and your customers.

What MOQs and costs should I expect?

For simple, catalog ODM 4-in-1 brushes, you can find suppliers with MOQs as low as 100–500 units and unit prices under $2. For a fully custom OEM brush with a unique mechanism, expect higher MOQs (often starting at 1,000 units) and tooling costs, which will increase the unit price.

Conclusion

Define your brush functions first, anchor all materials in compliance early, and choose your manufacturing path wisely. This ensures your 4-in-1 brush is a success from concept to customer.

Références

-

Explore the versatility and convenience of a 4-in-1 brush for makeup enthusiasts. ↩

-

Get insights into production timelines and how to manage them effectively. ↩

-

Understand how ISO 9001 ensures quality management in manufacturing. ↩

-

Explore standards for hair fallout rates to ensure product quality. ↩

-

Learn about the engineering behind retractable mechanisms for durability. ↩

-

Understand the benefits of using PBT and Taklon fibers for brush performance. ↩

-

Learn about the significance of FSC certification for sustainable materials. ↩