Sourcing makeup brushes1 feels complex. You see endless options for materials and shapes. This guide connects history to your sourcing decisions, giving you the confidence to choose the right supplier.

Makeup brushes have no single inventor. They emerged in ancient cultures like Egypt and China, using animal hair2 tied to wood or bamboo. Craftsmanship from Europe and Asia refined their shapes, while 20th-century synthetics made them accessible, cruelty-free, and high-performing for modern formulas.

Understanding where brushes came from is more than a fun fact. As a brand founder or sourcing manager, this history gives you a framework for making smarter decisions. It helps you understand why certain materials perform better, why quality standards3 exist, and why the global supply chain looks the way it does today. When I started my career on a brush factory floor, I saw how these historical threads come together in every single brush we made. This knowledge helps my clients specify better products and avoid common sourcing mistakes. Let’s walk through this history, and I’ll show you how it connects directly to your business.

Makeup brushes were invented by Cleopatra in Ancient Egypt.Faux

While Egyptians used kohl applicators, brushes evolved independently across multiple cultures, including ancient China. There is no single credited inventor.

The basic structure of a makeup brush—handle, ferrule, and bristles—was standardized during the 20th century's mass production era.Vrai

Industrialization allowed for the consistent manufacturing of metal ferrules and shaped handles, creating the modern brush form we recognize today.

When and Where Did the First Makeup Brushes Appear?

You’re looking for the origin story of your product. But the history is scattered and unclear. I’ll give you the clear, concise answer you need for your brand’s storytelling.

The earliest "makeup brushes" weren’t one invention but a gradual evolution. Tools appeared independently in Ancient Egypt for applying kohl and in early Chinese dynasties, where artisans bundled animal hair to bamboo sticks for calligraphy and, eventually, cosmetics. There is no single "first" brush.

The Two Cradles of Brush Craft

The story of the makeup brush begins in two different parts of the world, for two different reasons. Understanding this helps explain the variety we see today.

-

Ancient Egypt (c. 3100 BCE): The focus here was function. Egyptians used small, stick-like applicators made of wood, ivory, or bone to apply kohl eyeliner and galena-based eyeshadows. These were more like styluses than the fluffy brushes we know, but they represent the first dedicated tools for applying cosmetics to the face. Their purpose was purely practical: getting product from pot to eye.

-

Ancient China (c. 200 BCE): In contrast, early Chinese brushes evolved from the art of calligraphy. Artisans mastered bundling animal hairs (like goat and rabbit) into bamboo handles. This craft focused on precision, control, and the tool’s ability to hold and release pigment smoothly. This tradition of expert hair bundling is the direct ancestor of the high-quality, hand-shaped brushes we source from Asia today.

This dual history is why we have such a diverse market. Some brushes are simple, functional applicators, while others are complex, artisanal tools.

The first makeup brushes were made exclusively from squirrel hair.Faux

Early brushes used a variety of available animal hairs, including goat, badger, and horse, depending on the region and intended use.

Ancient Egyptian kohl applicators are considered precursors to modern eyeliner brushes.Vrai

These early tools were designed for the specific task of lining the eyes, establishing the concept of function-specific cosmetic applicators.

How Did Brush Materials Evolve From Animal Hair to Synthetic Fibers?

Your customers demand vegan and cruelty-free4 products. But you also need high performance. Understanding material history helps you choose fibers that meet both ethical and quality standards for your brand.

Natural animal hair was the only option for centuries, prized for its softness and powder pickup. But the 1970s introduced synthetic fibers5 like Taklon and PBT, offering a durable, hygienic, and cruelty-free alternative that excelled with modern cream and liquid formulas.

The journey from animal hair to advanced synthetics is central to modern brush sourcing. Each step was a response to new cosmetic formulas, changing ethics, and manufacturing technology. When I work with brands, we often discuss this evolution to decide on the perfect fiber for their products.

From Natural Textures to Engineered Performance

The materials define how a brush performs. Here’s a quick breakdown of the key shifts.

| Era | Primary Materials | Key Characteristics & Use Case |

|---|---|---|

| Ancient-Renaissance | Goat, Squirrel, Weasel, Horse Hair | Natural cuticles picked up powders well. Prized for softness and blending. Used for loose powders and pigments. |

| 20th Century | Mass-produced Animal Hairs | Consistency improved, but quality varied. Still the standard for powder-based cosmetics like blush and eyeshadow. |

| 1970s-1990s | Early Synthetics (e.g., Taklon) | Less absorbent, making them ideal for new liquid/cream foundations. Offered a cruelty-free and more hygienic option. |

| 2000s-Today | Advanced Synthetics (PBT, Custom Filaments) | Engineered with tapered tips, textured surfaces, and antimicrobial coatings to mimic natural hair performance while being vegan and more durable. |

Today, you don’t have to choose between performance and ethics. Modern synthetic fibers are engineered to provide the best of both worlds. For example, we can source fibers with "flagged" tips that mimic a goat hair’s ability to pick up powder, or smooth, non-absorbent filaments perfect for a creamy concealer. This history directly informs the technical specifications you can request from a manufacturer like us.

Synthetic brushes became popular because they were cheaper to make than animal hair brushes.Faux

While cost was a factor, the primary drivers were the rise of cruelty-free consumer demand and the superior performance of synthetics with new liquid and cream makeup formulas.

Modern synthetic PBT fibers can be engineered to mimic the texture and performance of natural animal hair.Vrai

Innovations like tapered filaments and surface texturing allow synthetic fibers to pick up and blend powders effectively, rivaling the performance of traditional goat or squirrel hair.

Why Are China and Japan the Top Hubs for Makeup Brush Manufacturing?

You need a reliable supplier who can deliver quality, customization, and good value. Understanding why manufacturing is centered in East Asia6 helps you find the right OEM/ODM partner.

China and Japan became manufacturing hubs because they combine a deep history of artisanal brush-making with modern, efficient supply chains. This legacy of craftsmanship, plus access to materials and skilled labor, created the perfect environment for today’s advanced OEM/ODM ecosystem.

When I decided to build my own brush factory, I chose China for a reason. It’s not just about cost. It’s about a centuries-old tradition of craftsmanship that is literally in the DNA of the workforce here. This expertise, which started with calligraphy brushes, evolved and was refined in Japan, particularly in regions like Kumano, which set the global benchmark for luxury brush quality.

The Pillars of East Asian Dominance

This leadership in the brush industry didn’t happen overnight. It rests on three key pillars that are critical for B2B buyers today.

-

Legacy of Craftsmanship: The art of selecting, bundling, and hand-shaping bristles is a skill passed down through generations. This expertise ensures a level of quality in tuft density, shape retention, and softness that machines cannot replicate. When you specify a hand-finished brush, you are tapping into this historical tradition.

-

Integrated Supply Chains: Decades of manufacturing have built a powerful ecosystem. Raw material suppliers for fibers, ferrules (the metal part), and handles (wood, bamboo, plastic) are all located within close proximity to factories. This integration speeds up sampling, production, and allows for incredible customization.

-

Mature OEM/ODM Systems: Factories in China are built for partnership. We understand the needs of global brands, from low MOQs for startups to large-scale production runs. We have systems for custom tooling, logo printing, and packaging, making us a one-stop shop. This is why founders like Emily can bring a unique vision to life without building their own factory.

Japan is known for the world's most luxurious, handcrafted makeup brushes.Vrai

Regions like Kumano, Japan, are globally renowned for their artisanal 'fude' brush-making tradition, which sets the standard for high-end, hand-finished cosmetic tools.

All makeup brushes made in China are mass-produced and low-quality.Faux

China is a global hub for both mass-market and premium, handcrafted brushes, leveraging its deep history of craftsmanship to serve all segments of the beauty market.

What Modern Innovations Should You Look For When Sourcing Brushes?

You want your brand to stand out with products that are modern, responsible, and high-performing. Knowing the latest trends helps you write better product specs and meet market demands.

Today’s key innovations are in sustainable materials, advanced synthetic fibers7, and functional enhancements. For B2B buyers, this means specifying cruelty-free, vegan fibers with antimicrobial properties, and using recycled or FSC-certified materials for handles and packaging to meet EU and US compliance.

The history of the makeup brush is all about evolution. Today, that evolution is moving faster than ever. As a brand owner, you need to be aware of the innovations that matter most to consumers and regulators. These are the features that can give your product a real competitive edge.

Key Specs for a Modern Brush Line

When I consult with clients, we focus on innovations that deliver real value. Here are the top three areas to focus on in your sourcing brief:

-

Sustainability and Compliance: This is non-negotiable for US and EU markets. Your customers want to see it, and regulations demand it.

- Handles: Specify Forest Stewardship Council (FSC) certified wood or bamboo. You can also use recycled plastics (PCR) or aluminum.

- Ferrules: Ask for recycled aluminum.

- Compliance: Ensure your supplier can provide documentation for regulations like EU REACH and California Prop 65, which restrict certain chemicals in paints, glues, and materials.

-

Advanced Synthetic Fibers: The conversation is no longer just "synthetic vs. natural."

- Vegan & Cruelty-Free: This must be a baseline requirement.

- Performance: Specify fibers engineered for your formulas. For example, request tapered PBT filaments for powders or smooth, treated fibers for better slip with foundations.

- Hygiene: Ask about antimicrobial treatments for bristles, which is a strong selling point for consumers.

-

Ergonomics and Design: A brush must feel as good as it looks.

- Handle Design: Consider unique shapes, weights, and finishes that improve grip and control. This is a great area for brand differentiation.

- Ferrule Crimp: A double-crimped ferrule provides better stability and reduces shedding, a key indicator of quality.

FSC-certified wood is a key indicator of a sustainably sourced makeup brush.Vrai

The Forest Stewardship Council (FSC) certification ensures that the wood used for brush handles comes from responsibly managed forests, a crucial claim for eco-conscious brands.

Ergonomic' is just a marketing buzzword with no real meaning for makeup brushes.Faux

Ergonomic design refers to specific handle shapes, weights, and materials engineered to improve user comfort, control, and application precision, reducing hand fatigue.

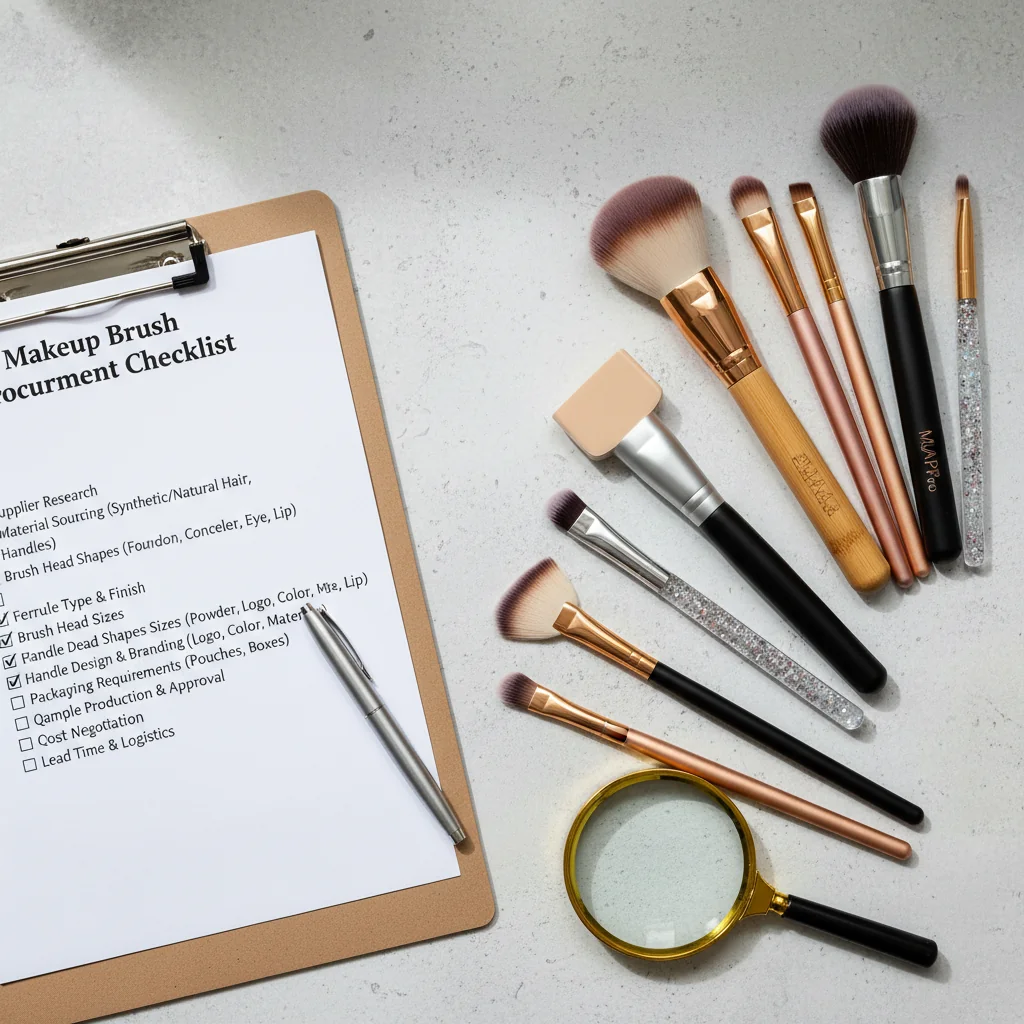

How Can This History Improve Your Procurement Checklist?

You have the historical context. Now, how do you turn it into action? You need a practical checklist that ensures you source high-quality brushes that align with your brand.

Use this history to build a smarter sourcing brief. Map your cosmetic formula to the right fiber type, specify ferrule material and crimping for durability, and demand QC checkpoints based on historical craftsmanship standards. This turns history into a competitive advantage.

This is where everything comes together. All the history, materials science, and craftsmanship we’ve discussed can be translated into a powerful procurement checklist. From my years in manufacturing, I know that a detailed specification sheet is the single most important tool for getting the product you want. It eliminates ambiguity and protects your brand.

Your Sourcing Checklist: From Spec to Production

Use this table as a starting point for your next conversation with a potential supplier.

| Component | Key Specification | Why It Matters (Historical Context) |

|---|---|---|

| Fibers/Bristles | Formula-Specific Fiber: Tapered/flagged synthetics for powders; smooth PBT for liquids/creams. Vegan & Cruelty-Free. | Builds on the 1970s synthetic revolution, now engineered for specific performance needs. Meets modern ethical demands. |

| Ferrule | Material: Aluminum (cost-effective) or Copper/Brass (premium weight). Double Crimp. | The industrial-era innovation that holds the brush together. A double crimp is a modern quality standard to prevent shedding. |

| Handle | Material: FSC-certified wood8/bamboo, or recycled plastic/aluminum. Finish: Specify paint layers and request wear testing. | Reflects modern sustainability demands. Quality finishing prevents chipping and ensures longevity, a mark of good craftsmanship. |

| Assembly | Glue & Curing: Specify epoxy resin type and curing time standards. Hand-Finishing: Require checks for tuft shape and bristle alignment. | The invisible details that define quality. Proper gluing prevents shedding. Hand-finishing is a direct legacy of East Asian artisanal craft. |

| Compliance | Certifications: Request documentation for Vegan, Cruelty-Free, FSC, ISO. Chemical Safety: Confirm compliance with EU REACH / CA Prop 65. | Essential for market access in the West and for building trust with your customers. Protects your brand from liability. |

By being this specific, you show suppliers that you are a serious, knowledgeable partner. It ensures you get accurate samples, transparent pricing, and a final product that makes your brand proud.

A 'double crimp' on the ferrule is a premium feature that helps prevent bristle shedding.Vrai

The crimp is the part of the ferrule that physically secures the bristles. A double crimp provides a stronger, more durable hold, which is a key quality indicator.

The type of glue used to secure bristles is not important for brush quality.Faux

The adhesive (typically an epoxy resin) and the curing process are critical for preventing shedding and ensuring the long-term durability of the brush head.

Conclusion

From ancient tools to modern innovations, the history of makeup brushes provides a clear roadmap for sourcing. Use this knowledge to specify better materials, demand higher quality, and build your brand.

Références

-

Explore the various types of makeup brushes to understand their specific functions and how they can enhance your beauty routine. ↩

-

Discover the advantages of animal hair in makeup brushes and why they have been favored for centuries. ↩

-

Understand the quality standards that ensure high-performance makeup brushes and how to identify them. ↩

-

Explore the meaning of cruelty-free in beauty products and why it matters to consumers today. ↩

-

Understand the advantages of synthetic fibers in makeup brushes, including performance and ethical considerations. ↩

-

Find out why East Asia, particularly China and Japan, is known for its high-quality makeup brush manufacturing. ↩

-

Stay updated on the latest innovations in synthetic fibers that enhance the performance of makeup brushes. ↩

-

Learn about FSC certification and its significance in ensuring sustainable sourcing for beauty products. ↩