Feeling lost trying to create your own makeup brush line? The process can be overwhelming. I’ll show you the clear, step-by-step path from concept to a market-ready product.

To create custom brushes1, first define your specs like fiber, shape, and handle. Then, choose OEM for full control or ODM for speed. Approve samples, confirm certifications, lock in your price and timeline, and you’re ready for production and shipping.

The global makeup brush market is booming, and there’s never been a better time to launch your own line. But turning a great idea into a physical product that your customers will love requires making smart decisions from the very beginning. I’ve seen many brands struggle with the details, so I’ve broken down the four most critical areas you need to master. Let’s get started.

Natural hair is always better than synthetic for makeup brushes.False

Modern synthetics often outperform natural hair, especially for creams and liquids, and meet the growing demand for vegan and cruelty-free products.

The global makeup brush market is projected to grow to over $12 billion by 2034.True

Multiple market reports show a strong compound annual growth rate (CAGR) for the makeup tools industry, with some forecasts reaching USD 12.9B by 2034.

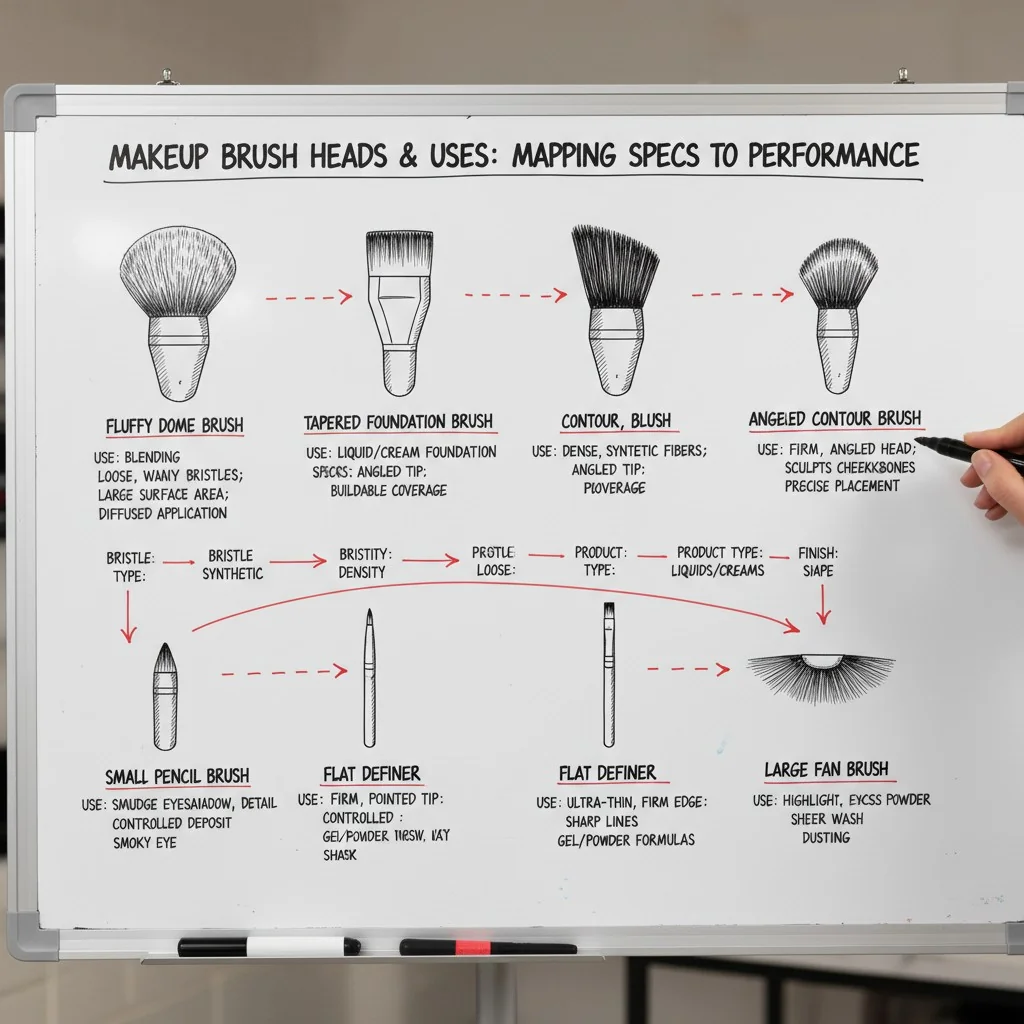

Design to Performance: How Do You Map Each Brush Spec to User Experience?

Worried your custom brushes won’t perform well? A beautiful design means nothing if it streaks or sheds. I’ll teach you how to link every spec to a perfect user experience.

Match hair type to formula (synthetics for creams), density2 to coverage (denser for more), and shape to precision (tapered for detail). Every choice, from the ferrule metal to the handle finish, directly impacts how the brush applies makeup and how long it lasts.

When I first started in this industry on the factory floor, I was amazed at how a tiny change in a brush’s design could completely alter its performance. It’s not just about looks; it’s about function. Let’s break down the key components so you can build a brush that truly performs for your customers.

Hair/Fiber: The Heart of the Brush

Modern synthetic fibers are my top recommendation. They’ve come so far and now rival natural hair, plus they meet the growing demand for vegan and cruelty-free products. For powders, you want fibers with some crimp to pick up product well. For creams and liquids, go for straight, tapered synthetics to avoid streaking and product absorption.

Shape and Density: The Application Engine

The shape and density control how the product is applied. A tapered head is perfect for precise highlighter application, while a dense, flat kabuki gives you maximum foundation coverage. Duo-fiber brushes, with their mix of long and short bristles, are great for sheer, buildable layers. Think about the formula’s viscosity—thicker formulas need denser brushes.

Ferrule and Handle: The Foundation of Quality

The ferrule3 holds it all together. Aluminum is a great, cost-effective choice, but for a premium line, brass is better because it resists corrosion and holds its shape longer. The handle is your customer’s first touchpoint. Using FSC-certified wood and waterborne paints shows a commitment to sustainability. Always ask your manufacturer for pull tests on the ferrule and hardness tests on the handle paint to prevent chipping.

| Brush Spec | User Experience Outcome | My Recommendation |

|---|---|---|

| fiber type4 | Pick-up, laydown, formula compatibility | Tapered synthetics for liquids; crimped synthetics for powders. |

| Density | Coverage level (sheer to full) | Higher density for viscous formulas and full coverage. |

| Shape | Precision vs. blending | Tapered for precision; rounded/flat for blending/coverage. |

| Ferrule | Durability, longevity | Brass for premium lines; aluminum for cost-performance. |

| Handle | Feel, sustainability, durability | FSC wood with waterborne paint and a hard topcoat. |

Modern synthetic fibers can be engineered to outperform natural hair for liquid foundation.True

Straight, non-porous synthetic fibers reduce product absorption and prevent streaking with liquid and cream formulas, leading to a smoother application.

The handle material of a makeup brush only affects its appearance.False

Handle material and finish also impact the brush's durability, weight, balance, and can support sustainability claims (e.g., using FSC-certified wood).

OEM vs. ODM: How Do You Choose the Right Path, MOQs, and Timeline?

Confused between OEM5 and ODM for your brushes? The wrong choice can cost you time, money, and brand identity. I’ll help you decide the best path for your specific goals.

Choose OEM (Original Equipment Manufacturer) for a fully custom brush where you own the design IP—ideal for brand differentiation but with higher MOQs. Pick ODM6 (Original Design Manufacturer) to customize existing factory designs for a faster launch with lower MOQs.

I work with brands of all sizes, from startups to established names, and the OEM vs. ODM question comes up every time. There’s no single right answer; it depends entirely on your budget, timeline, and brand strategy. Making the right choice upfront is one of the most important decisions for your brand.

OEM: Your Vision, Your IP

OEM is for the brand founder with a very specific, unique vision. You control every single detail, from the fiber geometry to the handle weight. This gives you a truly unique product and stronger intellectual property (IP) protection. I recommend this path for brands that want to build a strong, differentiated identity. However, this path requires more investment in time and money. Custom tooling often needs to be made, and development takes longer.

ODM: Speed to Market

ODM is perfect for brands that need to launch quickly and with a smaller initial investment. You start with a manufacturer’s existing, proven brush designs and customize the color, logo, and packaging. You can sometimes make small tweaks to the brush head, too. This significantly cuts down development time and lowers the Minimum Order Quantity (MOQ), making it a great option for new brands or limited edition collections.

Here’s a quick comparison based on what I see in my factory every day:

| Factor | OEM (Original Equipment Manufacturer) | ODM (Original Design Manufacturer) |

|---|---|---|

| Customization | 100% custom, full spec control | Based on existing designs; logo, color, packaging |

| IP Ownership | Brand owns the design | Manufacturer owns the base design |

| Timeline | Longer (6-10 weeks development) | Faster (2-4 weeks development) |

| MOQ | Higher (500–2,000 units/SKU) | Lower (200–500 sets) |

| Cost | Higher upfront tooling/development | Lower upfront costs |

OEM manufacturing typically requires a higher Minimum Order Quantity (MOQ) than ODM.True

OEM involves creating custom tooling and unique production runs, which makes it less cost-effective for factories at very low quantities, hence the higher MOQ.

With ODM, you can change any part of the brush you want.False

ODM customization is generally limited to surface-level aspects like color, logo, and packaging. Major changes to the brush shape or structure are not possible as it uses existing molds.

Certifications, Compliance, and Labeling: What Must Brands Prepare?

Worried about legal compliance for your brushes? Getting it wrong can lead to costly recalls and damage your brand’s trust. I’ll outline the key certifications7 and labeling you must have.

Ensure your manufacturer has ISO 9001 for quality. Your materials must comply with EU REACH and US Prop 65. Get documentation for vegan/cruelty-free claims, and make sure your labeling includes origin, materials, and any required recycling marks.

Navigating the world of international compliance can feel like a minefield, but it’s non-negotiable for building a reputable brand. I’ve helped hundreds of clients get their products ready for U.S. and EU markets, and it always comes down to these key areas. Don’t let this part intimidate you; a good partner will guide you through it.

Quality and Material Safety

First, ask if your factory is ISO 9001 certified. This shows they have a reliable quality management system in place. For materials, your products must meet standards like REACH in the EU (which checks for harmful chemicals) and Prop 65 in California. If you’re making vegan or cruelty-free claims, you need proof from the entire supply chain that no animal products or testing were involved. Ask for these documents early.

Logo Durability and Labeling

Your logo is your brand’s signature—it has to last. Don’t just accept a printed logo; demand durability tests. We use rub tests with alcohol and solvents to ensure the logo won’t wear off after a few cleanings. For labeling, be precise. Your packaging must clearly state the country of origin, material composition (e.g., "Synthetic Fiber, Aluminum, FSC Wood"), and any relevant recycling symbols. This transparency builds trust with both retailers and customers.

| Compliance Area | What to Prepare/Request | Why It Matters |

|---|---|---|

| Quality System | ISO 9001 Certificate | Ensures consistent manufacturing processes. |

| Material Safety | REACH / Prop 65 Test Reports | Required for legal sale in EU/US markets. |

| Ethical Claims | Vegan / Cruelty-Free Declarations | Substantiates marketing claims and builds brand trust. |

| Logo Durability | Abrasion & Solvent Rub Test Results | Prevents logo from fading, protecting brand image. |

| Packaging Label | Country of Origin, Materials, SKU | Fulfills import requirements and informs consumers. |

Making a 'vegan' claim requires documentation for the entire supply chain.True

To be truly vegan, the fibers, glues, and even handle coatings must be proven to be free of animal-derived ingredients, not just the final assembled product.

ISO 9001 certification guarantees that every single brush will be perfect.False

ISO 9001 certifies that a factory has a consistent quality management system to control processes and reduce defects, but it does not guarantee zero defects in every unit.

Price, Lead Time, and Sampling: What’s a Realistic Planning Checklist?

Trying to budget for your brush launch without real numbers? Unrealistic plans can derail your launch and drain your cash. Here’s a checklist with industry-standard costs and timelines.

Plan for single eye brushes around $0.50–$1.20 and face brushes at $1.20–$3.50 (ex-factory). Factor in 1-3 weeks per sample round and 30-45 days for mass production. Add another 1-4 weeks for shipping to be safe.

Let’s talk numbers. This is where your vision meets reality. As a factory owner, I believe in being transparent about costs and timelines so you can plan effectively. The global market for makeup tools is growing fast, showing a huge opportunity for new brands that plan well.

| Market Data Source | 2023/2024 Value | Forecast Value | CAGR |

|---|---|---|---|

| Source 1 | USD 7.0B (2024) | USD 12.9B (2034) | ~6.3% |

| Source 2 | USD 3.72B (2024) | USD 6.3B (2035) | ~4.91% |

| Source 3 | USD 1.5B (2023) | USD 2.6B (2032) | ~6.1% |

(Note: These figures vary based on the report’s scope, but all show strong growth.)

What Drives Your Price?

The biggest cost drivers are the fiber grade, the ferrule metal (brass costs more than aluminum), the handle material8 and finish, and your packaging. A complex 12-piece set in a premium box will have a much higher unit cost than a single brush in a polybag. Be clear about your quality level to get an accurate quote.

A Realistic Timeline

Here’s a typical timeline to build into your launch plan:

- Sampling: 7–21 days for each round. Most brands go through 1-3 rounds to get it perfect. Don’t rush this step.

- Mass Production: 30–45 days after you approve the final sample.

- Shipping: This is the wild card. Air freight is fast (about 1 week) but expensive. Sea freight is much cheaper but takes 3-4 weeks or more. Always build a buffer into your launch plan for potential shipping delays.

Finally, get everything in writing. Your contract should lock in prices, MOQs, and detailed quality standards, like maximum shedding counts and pull strength for the ferrule.

The choice between air and sea freight can impact your product launch timeline by several weeks.True

Sea freight typically takes 3-4 weeks longer than air freight. This time difference is critical for meeting seasonal launch dates or retail deadlines.

The ex-factory price of a brush is the final cost you will pay.False

The ex-factory price does not include shipping, import duties, taxes, or local logistics. You must add these costs to calculate the final 'landed cost' per unit.

Conclusion

Creating your own makeup brush line is achievable with the right knowledge and partner. By focusing on these four key areas, you can launch a high-quality, compliant, and successful brand.

References

-

Explore how custom brushes can enhance your makeup application and brand identity. ↩

-

Understanding brush density can help you select the right tools for various makeup techniques. ↩

-

Learn about the ferrule’s importance in brush construction and durability. ↩

-

Discover the impact of different fiber types on makeup application and user experience. ↩

-

Understanding OEM can help you make informed decisions about your product development. ↩

-

Learn the differences between ODM and OEM to choose the best manufacturing option for your brand. ↩

-

Ensure your products meet industry standards by understanding essential certifications. ↩

-

Explore how different handle materials can influence the feel and performance of brushes. ↩