You have a brilliant idea for a makeup brush, but the path from concept to reality feels blocked. Consumer DIY guides are too simple, and professional suppliers seem intimidating.

To create a custom makeup brush, you must define its use, select a head shape and PBT fiber1, and choose a ferrule. Then, assemble with strong adhesive, trim the tuft, and cure. Finally, test for shedding, bond strength, and application performance before mass production.

I remember my early days on the factory floor, watching brands struggle to communicate their vision. They knew what they wanted, but they didn’t know the language of manufacturing. They would get samples that were "close but not quite right," and the process would drag on, costing them time and money. It’s a pain point I see with so many founders like Emily, who are full of passion but need a clear, reliable process.

That’s why I want to pull back the curtain. Creating a professional-quality brush isn’t magic; it’s a series of specific, measurable steps. Whether you’re making a single prototype or launching a full line, this is the blueprint you need. Let’s build your brush, together.

All professional makeup brushes use natural animal hair for the best performance.False

This is outdated. Modern synthetic fibers, especially tapered PBT (Taklon), now match or even exceed the performance of natural hair in pickup and application, plus they are more durable, hygienic, and cruelty-free.

The diameter of a synthetic bristle directly impacts the brush's softness and pickup ability.True

Correct. Smaller diameter fibers (e.g., 0.05mm) create a softer, silkier feel ideal for powders, while slightly larger diameters can provide more structure for cream or liquid products.

From Idea to Prototype: What Are the Exact Steps to Design and Test a Custom Brush?

Turning your brush concept into a physical prototype feels like a huge leap. You worry that one wrong choice will lead to a brush that sheds, feels scratchy, or just doesn’t work.

Here is the professional workflow. Define the brush’s function, choose the right components, assemble it correctly, and test it against clear, professional standards. This process removes the guesswork and ensures your final product is something you can be proud of.

I’ve helped hundreds of brands like yours navigate this exact process. The key is to be systematic. Don’t just tell a factory "I want a powder brush." Give them the specifications. This not only ensures you get what you want but also shows the supplier that you are a serious, knowledgeable partner. It all starts with a clear plan.

1. Design and Specification

First, define the brush’s job. Is it for loose powder, liquid foundation, or cream blush? This determines everything else. For powders, you’ll likely want a rounded, fluffy head for blending. For precise application like eyeliner or concealer, a flat or angled shape is better. Next, choose your bristle fiber. Tapered PBT is the industry standard. The key is specifying the diameter—smaller diameters feel much softer.

2. Assembly and Finishing

Once you have your components (bristle tuft, ferrule2, handle), assembly begins. The ferrule must have a tight tolerance to grip the handle and bristles properly. We use a high-grade epoxy adhesive to secure the bristle tuft inside the ferrule. After the adhesive is applied, the brush head is trimmed and shaped. We use special combs, razors, and sometimes a light flame-finishing technique to create the perfect taper and softness. The brush then needs to cure for the time specified by the adhesive manufacturer to ensure maximum bond strength.

3. Validation and Testing

This is the step that separates amateur DIY from professional OEM quality. Before you approve a sample for production, it must pass a series of tests.

| Test Metric | Pass/Fail Standard | Why It Matters |

|---|---|---|

| Shed Rate | ≤1–2 hairs per 100 strokes | Ensures the brush won’t leave bristles on the user’s face. |

| Ferrule Pull Strength | ≥10–15 Newtons (N) | Guarantees the head won’t detach from the handle during use. |

| Cleaning Durability | No loosening after 50-100 wash cycles | Confirms the brush can withstand regular cleaning without falling apart. |

| Application Test | Uniform application, no streaking | The ultimate test: Does the brush perform its function flawlessly? |

Documenting these results is critical. It creates a quality standard for your bulk order.

A good makeup brush should never shed a single hair.False

Even high-quality brushes may shed 1-2 hairs during the first few uses or after 100 strokes in a lab test. The standard is a minimal shed rate, not zero shedding, which is nearly impossible to guarantee.

The adhesive used to bind the bristles is as important as the bristles themselves.True

Absolutely. A weak or improperly cured adhesive is the number one cause of shedding and ferrule failure. A strong, durable epoxy is essential for a long-lasting, professional-grade brush.

Materials That Matter: How Do You Choose Between PBT vs. Nylon, Ferrule Metals, and Sustainable Handles?

Looking at a supplier’s material list can be overwhelming. PBT, nylon, aluminum, copper, FSC wood… what do these terms even mean for your brush? Making the wrong choice can compromise your brush’s performance, its feel, and even your brand’s story.

Let’s break down the core components. Tapered PBT is the modern go-to for soft, effective bristles. For the ferrule, aluminum is the versatile workhorse, while copper adds a touch of luxury. For handles, sustainable options like FSC wood are in high demand.

I always tell my clients that materials tell a story. A heavy, cool-to-the-touch brass ferrule tells a story of luxury. A handle made from FSC-certified wood tells a story of sustainability3. Your material choices are a direct reflection of your brand’s values. Let’s make sure you’re choosing materials that tell the right story for you.

Bristle Fibers: Performance is in the Details

The debate between natural and synthetic hair is over. Modern synthetics won. The best choice today is PBT (Polybutylene Terephthalate), often marketed as Taklon. Its advantage comes from the ability to create finely tapered tips, which mimic the softness and pickup of natural hair. Older nylon bristles are stiffer and less effective. Within PBT, you can specify fiber diameter to control performance. For extra brand value, you can even request antimicrobial-treated fibers for clients focused on hygiene.

Ferrules: The Unsung Hero

The ferrule is the metal band that connects the bristles to the handle. It’s crucial for the brush’s durability and balance.

| Ferrule Material | Pros | Cons | Best For |

|---|---|---|---|

| Aluminum | Lightweight, lower cost, easily colored via anodizing. | Softer, can be dented more easily. | Volume-driven lines, colorful designs, value-focused brands. |

| Copper/Brass | Heavier, premium feel, very durable, beautiful plated finishes. | Higher cost, adds weight to the brush. | Luxury brands, durable professional kits, high-end aesthetics. |

Handles: Your Brand’s Touchpoint

The handle is where your customer connects with the product. FSC-certified wood is a fantastic choice for eco-conscious brands. It shows a commitment to responsible forestry. Recycled aluminum offers a sleek, modern, and durable option with a great sustainability story. Newer materials like bioresins (derived from corn or sugarcane) are also emerging for brands that want to lead with innovation.

Copper ferrules are always better than aluminum ferrules.False

'Better' depends on the goal. Copper is more durable and feels more luxurious, but it's also heavier and more expensive. Aluminum is lightweight, cost-effective, and offers more color flexibility, making it a better choice for many brands.

PBT and Taklon are two different types of synthetic bristles.False

This is a common point of confusion. Taklon is a brand name for a high-quality PBT synthetic fiber. They are essentially the same material, known for its soft, tapered tips.

Quality Control Checklist: What Are the 12 Tests for OEM-Grade Performance?

You approved a perfect sample. But how can you be sure the 10,000 brushes in your bulk order will have the same quality? This is a major fear for brand founders. Without a strict quality control4 (QC) process, you risk receiving a batch of products that could ruin your launch and your reputation.

Here is the 12-point checklist we use at Brushino to guarantee OEM-grade performance. A reliable manufacturing partner should be able to perform these tests and provide you with a formal QA report for every batch.

When I started my own factory, implementing a rigorous QC system was my top priority. I had seen too many brands get burned by suppliers who cut corners on the bulk order after sending a perfect "golden sample." This checklist isn’t just about finding defects; it’s about creating a partnership built on trust and transparency. Ask your supplier about their QC process. If they can’t answer, that’s a major red flag.

The 12-Point OEM QC Checklist

- Application Uniformity: Field test with actual makeup to ensure smooth, streak-free results.

- Shed Count: A controlled test (e.g., 100 strokes on a textured surface) to count shed hairs.

- Ferrule Bond Strength (Pull Test): A machine pulls the head and handle apart to measure the force required to break the bond.

- Ferrule Bond Strength (Torque Test): A machine twists the ferrule and handle to test the adhesive5‘s resistance to rotational force.

- Corrosion Resistance: The ferrule is subjected to a salt-spray test to simulate aging and ensure it won’t tarnish.

- Bristle Alignment Tolerance: Microscopic inspection to ensure bristles are uniform and free of strays.

- Cleaning Cycles Durability: The brush is repeatedly washed with soap and/or oil-based cleaners to check for bristle damage or loosening.

- Allergen/Hygiene Screening: Material testing to ensure components are free from common irritants and contaminants.

- Coating Colorfastness: The handle and ferrule coatings are rubbed with solvents to ensure the color won’t fade or transfer.

- Logo Abrasion Resistance: The printed logo is tested for durability against rubbing and scratching.

- Packaging Drop Tests: The final packaged product is dropped from various heights and angles to ensure it protects the brush during shipping.

- Thermal/Humidity Aging: Brushes are placed in environmental chambers to simulate different climates and check for warping or material degradation.

A simple 'pull test' by hand is enough to check brush quality.False

A hand pull is subjective. A professional pull test uses a calibrated force gauge to apply a specific amount of force (e.g., 10-15 Newtons) for a quantifiable and repeatable result, which is essential for consistent quality control.

Salt-spray testing is a standard procedure for checking the quality of metal ferrules.True

Yes, this is a common accelerated corrosion test. It ensures that the ferrule's plating or anodizing is sufficient to prevent tarnishing and rust during the brush's lifetime, especially in humid environments.

Market and Sustainability Signals: What Should You Prioritize for 2025?

The beauty market is always changing. Launching a brush line based on last year’s trends is a recipe for failure. You need to know where the market is heading to build a brand that lasts. Investing in the wrong trend can be a costly mistake.

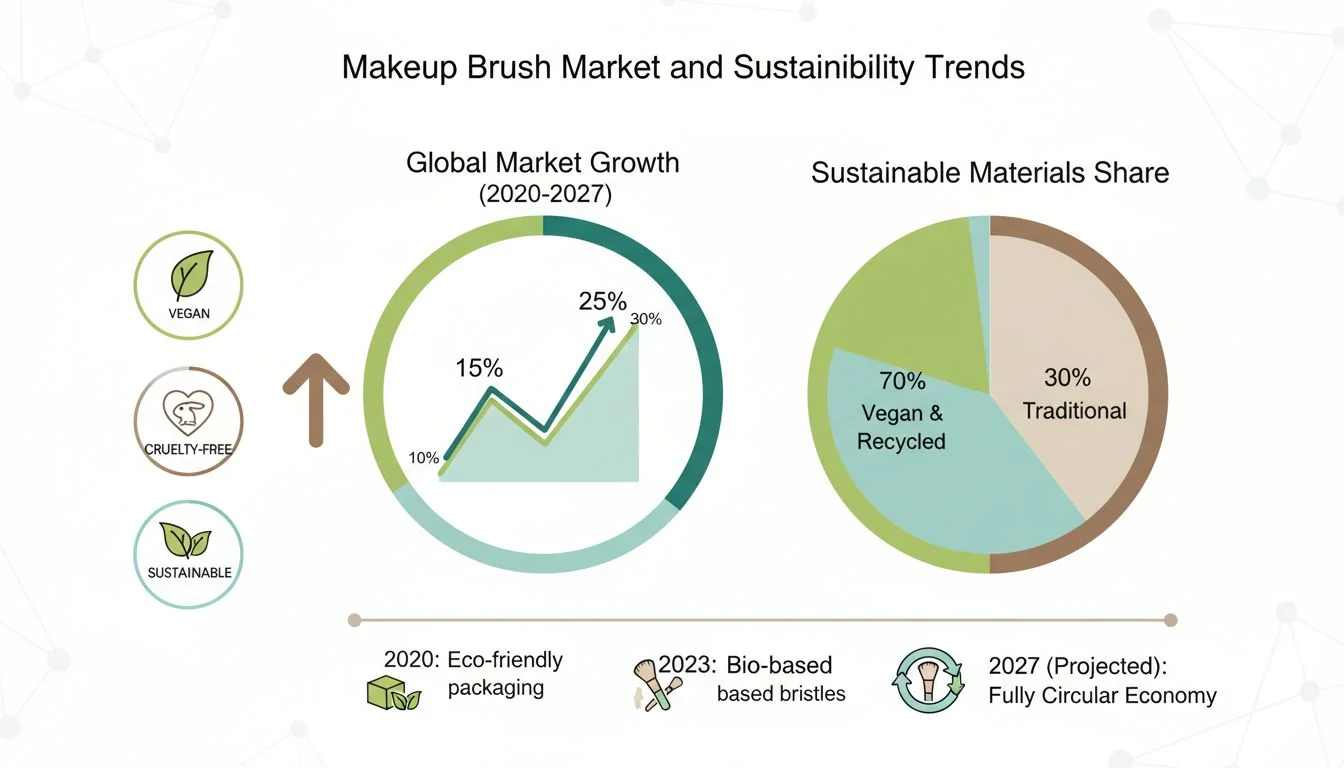

Let’s look at the data. The market is growing, and the demand for vegan and sustainable products is not just a trend—it’s the new standard. I’ll show you the key signals to focus on for a successful launch in 2025 and beyond.

When I talk to brand founders, their biggest question is often "Is it worth it?" They want to know if there’s still room in the market. The answer is a resounding yes, but you have to be smart. You can’t just launch another generic brush set. You have to tap into what today’s consumers truly care about.

Understanding the Market Size

When you research the makeup brush market, you’ll see conflicting numbers. Here’s why. A broad report from a source like GM Insights might value the "Makeup Brush & Tools" market at USD 7.0 billion in 2024. This number is large because it includes sponges, applicators, and other tools. A more focused report might cite the "Makeup Brushes Only" market at USD 1.47 billion in 2024. Both numbers are useful. Use the larger one to show the overall category health and the smaller one to show the specific niche you’re targeting. The good news is both are growing at a healthy rate (5-7% CAGR).

The Shift to Conscious Beauty

This is the most important trend.

- Vegan Dominance: synthetic fibers6 (PBT) have almost completely replaced animal hair due to performance, ethics, and hygiene.

- Sustainability is Key: Brands are winning by using FSC-certified wood, recycled aluminum ferrules, and eco-friendly packaging. Innovative concepts like ferrule-less brushes (where the bristles are set directly into a wooden handle) are gaining traction as they reduce metal usage.

- Offline Still Matters: Even with the rise of social commerce, about 65% of tool sales still happen offline. Customers want to touch and feel the quality of a brush before buying. This means your in-store presentation and packaging are critical.

What to Focus on for 2025

For your launch, prioritize a clear sustainability message. Lead with "100% Vegan & Cruelty-Free." Highlight your use of recycled or responsibly sourced materials. If you can, explore innovative designs like ferrule-less brushes to stand out. And if your brushes have unique properties, like antimicrobial fibers, make that a central part of your story.

The makeup brush market is shrinking due to the popularity of beauty sponges.False

The market is not shrinking. While sponges are popular, the overall market for brushes and tools is growing, with a projected CAGR of around 6.3%. Brushes offer a level of precision that sponges cannot, ensuring their continued demand.

Most makeup brush sales now happen online through social media.False

While online and social commerce are growing fast, offline retail still accounts for the majority of sales (~65% in 2024). Consumers value the ability to physically test the brush's softness and density before purchasing.

Conclusion

Creating your perfect custom brush is entirely within your reach. By focusing on smart material choices, following a rigorous testing process, and aligning with modern sustainability trends, you can succeed.

References

-

Learn about PBT fiber’s advantages in makeup brushes, including performance and durability. ↩

-

Understand the importance of the ferrule in ensuring the durability and balance of makeup brushes. ↩

-

Investigate how sustainable practices are shaping the future of the makeup brush market. ↩

-

Find out about essential quality control measures to ensure high standards in makeup brush production. ↩

-

Discover the best adhesives for assembling makeup brushes to prevent shedding and ensure quality. ↩

-

Explore the advantages of using synthetic fibers over natural hair in makeup brushes. ↩