You want to create brushes with that luxury feel, but the process seems like a secret. It’s frustrating. I’m here to show you exactly how it’s done.

Hermès gets brush samples using a dual model: French artisans1 for natural-hair brushes and certified Chinese OEMs for synthetic tools. Samples follow a strict tech pack, with timelines from 1-3 weeks for existing shapes and 3-6 weeks for fully custom designs, all verified by intense QC.

When I talk to brand founders, the name Hermès often comes up. It represents the peak of luxury, and their makeup brushes are no exception. The question I hear most is, "How do they do it?" It seems like a magic trick—getting perfect, consistent samples delivered fast. But it’s not magic. It’s a well-defined strategy. Many founders I work with, especially those just starting out, feel that this level of quality is out of reach. They believe you need a massive budget and connections to even start the conversation. I’m going to pull back the curtain and show you the exact sourcing, spec, and quality control2 systems that luxury houses use. More importantly, I’ll show you how you can apply these same principles to your own brand, no matter your size.

Hermès exclusively manufactures all its makeup brushes in France.False

This is false. Independent reviews and product markings show a dual-sourcing model. The natural-hair blush brush is made in France, while the synthetic travel brush is made in China.

Luxury brands like Hermès use a dual-sourcing strategy for their brush lines.True

This is true. They leverage French artisans for heritage and natural hair expertise, and certified Asian OEMs for the scalability and consistency of synthetic brushes.

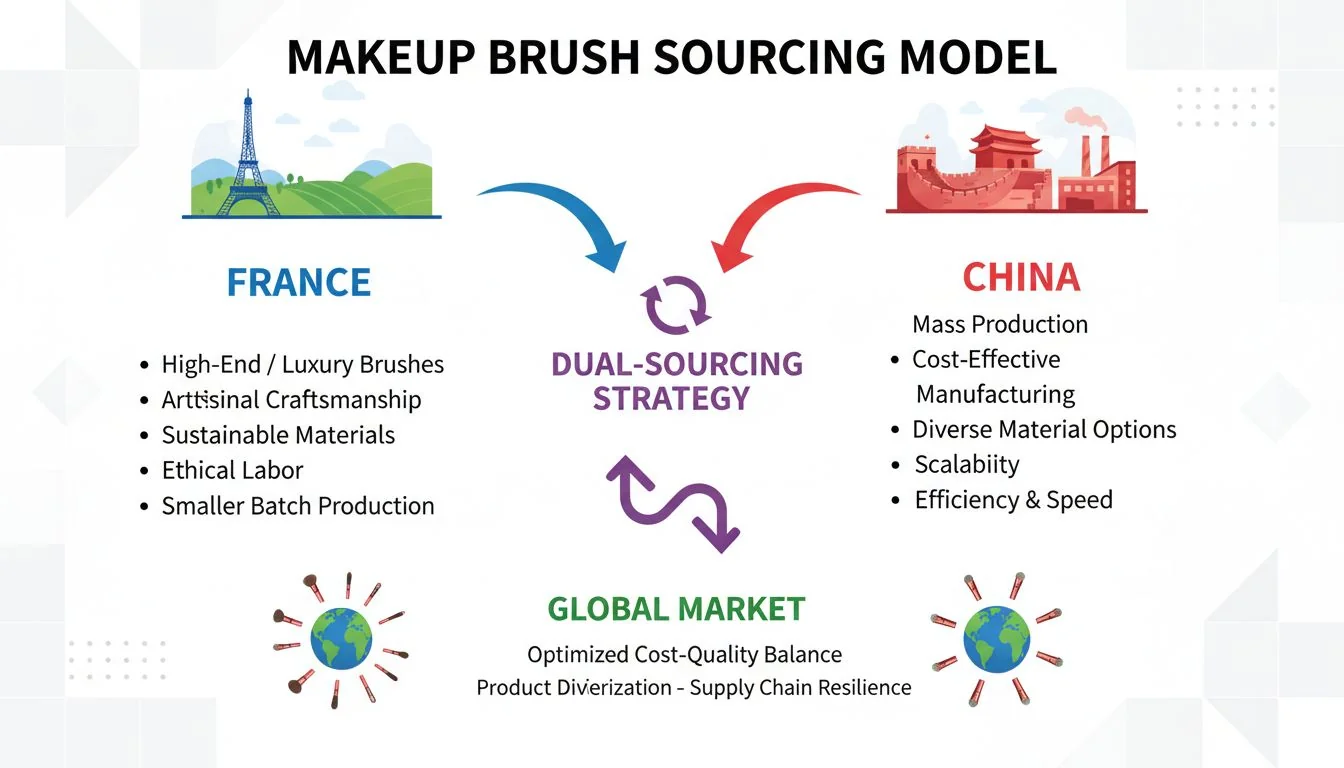

How Do Luxury Houses Source Brush Samples: France vs. Certified OEMs in Asia?

Wondering where to source brushes that feel truly high-end? France seems authentic but expensive, while Asia feels scalable but risky. The solution is understanding why luxury brands use both.

Luxury houses use a dual-sourcing model3. They partner with French artisans for prestige, natural-hair brushes and use certified Asian OEMs for synthetic brushes that require consistency, durability, and scale.

I remember a client, let’s call her Emily, who was determined to launch a brush that felt "uniquely European." She associated that feeling with French craftsmanship. The truth is, you can achieve that same luxury standard through a certified OEM partner if you know what to ask for. The Hermès model proves this. They don’t rely on a single source. Instead, they are strategic.

The Dual-Sourcing Strategy

For their most iconic pieces, like the $126 blush brush, they turn to French artisans. These workshops offer unparalleled skill with natural hair and a deep understanding of the brand’s aesthetic. It’s about heritage and a specific tactile experience.

However, for a tool like the synthetic travel brush, the priorities shift to durability, consistency, and precise engineering. This is where certified OEMs in Asia excel. They have the technology and scale to produce thousands of identical brushes that meet strict performance criteria. This split approach allows a brand like Hermès to get the best of both worlds: artisanal prestige and industrial precision.

| Sourcing Model | Best For | Key Advantages | Considerations |

|---|---|---|---|

| French Artisan | Natural Hair, Prestige SKUs | Heritage, unique feel, brand story | Higher cost, limited scale, longer lead times |

| Certified Asian OEM | Synthetic Fibers, Travel/Kit SKUs | Consistency, scalability, cost-efficiency, speed | Requires strict vetting and QC |

All high-end makeup brushes are made with natural animal hair.False

This is false. Many luxury brands, including Hermès, use high-performance synthetic fibers for certain brushes, especially for travel or specific application needs, due to their durability and consistency.

The origin of a Hermès brush can depend on its materials and intended use.True

This is true. Expert analysis confirms their goat hair blush brush is made in France, while the synthetic travel brush is made in China, demonstrating a strategy of sourcing based on the specific SKU's requirements.

What Specs Make the Cut: Hair Grade, Ferrule Metal, Handle Lacquer, and Softness Benchmarks?

Your samples arrive, but they just don’t have that "wow" factor. You’re not sure what specific details to ask for. The secret to a luxury brush is in the technical specifications.

Luxury brands approve samples based on a detailed tech pack4. This specifies everything from the goat hair grade and brass ferrule to the multi-layered lacquered wood handle and verified softness benchmarks.

A luxury brush isn’t just a tool; it’s an experience. That experience is built from a series of deliberate choices. When a brand like Hermès sends a brief to a manufacturer, it’s not a vague request. It’s a highly detailed technical document, or "tech pack," that leaves no room for error. We guide our clients to create these all the time, because clarity is what separates an okay sample from a perfect one. The manufacturer’s job is to replicate that vision perfectly. This is done by focusing on three core components and a final performance test.

Key Material Specifications

- Hair/Fibers: For their blush brush, Hermès uses high-grade goat hair5, known for its softness and powder pickup. For the travel brush, they use advanced synthetic fibers, chosen for durability and consistency.

- Ferrule: They use a brass ferrule6, not aluminum. Brass is heavier and gives the brush a balanced, substantial feel in the hand. It costs more, but it’s a non-negotiable part of the luxury experience.

- Handle: The handle is lacquered wood, often with multiple layers of color to achieve a specific depth and sheen. The shape is also ergonomically designed for comfort and control.

Finally, it’s all verified with performance benchmarks for softness, product pick-up, and application (splay).

| Component | Luxury Spec (e.g., Hermès) | Standard Spec | Why it Matters |

|---|---|---|---|

| Hair | High-Grade Goat Hair / Custom Synthetic | Standard Synthetic | Softness, performance, durability |

| Ferrule | Polished Brass | Aluminum | Weight, balance, premium feel |

| Handle | Multi-Layer Lacquered Wood | Painted Plastic / Basic Wood | Ergonomics, visual appeal, longevity |

The weight of a makeup brush has no impact on its perceived quality.False

This is false. Luxury brands often use heavier materials like brass for the ferrule specifically to give the brush a substantial, balanced, and premium feel in the hand.

The Hermès blush brush features a lacquered wood handle and a brass ferrule.True

This is true. Independent expert reviews have confirmed these material choices, which contribute to the brush's high-end positioning and price point.

From Brief to Counter: What Are Realistic Sample Timelines, QC Gates, and Compliance for Prestige Beauty?

Your samples are always late, and the quality is a gamble. These delays and inconsistencies are killing your launch schedule. You can avoid this by understanding the professional production timeline.

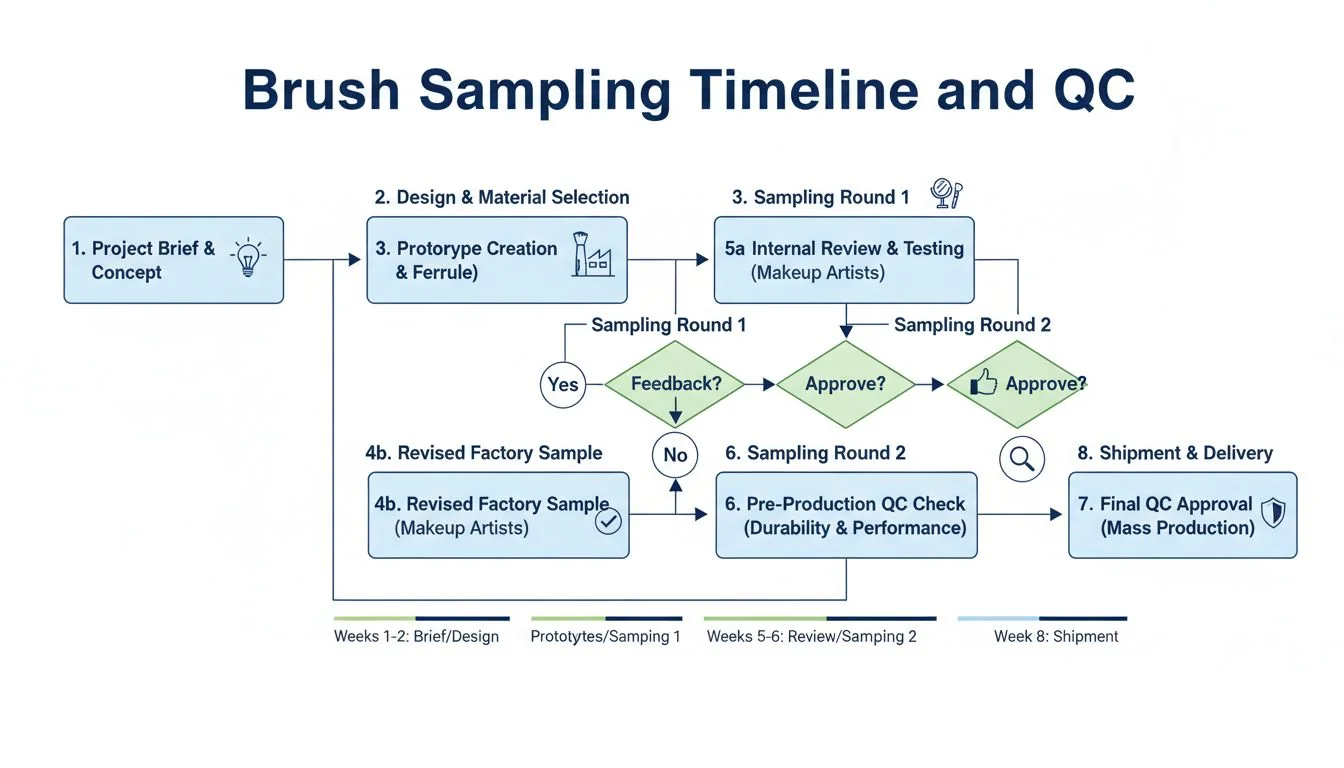

Samples based on a manufacturer’s existing designs (ODM) can take 1–3 weeks. Fully custom brushes (OEM) typically require 3–6 weeks. Quality is locked in with multi-stage QC and supplier certifications like ISO9001 and BSCI.

Speed and quality are not mutually exclusive, but they require a solid process. For luxury houses, getting a sample isn’t the end of a process; it’s a single step in a much larger quality assurance system. When we work with brands, we build this system from day one to prevent surprises. The timeline starts the moment a detailed brief is submitted.

The Path to an Approved Sample

- Timeline Expectations: The speed depends on the type of request. If you’re modifying an existing shape from a factory’s catalog (an ODM project), samples can be ready in 7-21 days. If you’re creating a completely new head and handle shape (a custom OEM project), expect a 3-6 week turnaround. Pre-booking raw materials can shorten these cycles.

- Quality Control (QC) Gates: Quality isn’t checked at the end; it’s monitored throughout. This includes raw material inspection (is the hair grade correct?), in-line audits during assembly (is the ferrule crimped properly?), and a final random sampling of finished goods. Top-tier OEMs report qualification rates of 99.5% or higher.

- Compliance and Certifications: Reputable suppliers for luxury brands hold key certifications like ISO9001 (quality management), BSCI/SMETA (ethical auditing), and FSC (sustainable wood). These aren’t just logos; they are proof of a reliable and ethical operation.

| Stage | Timeline | Key Action |

|---|---|---|

| Brief Submission | Day 1 | Brand provides detailed tech pack. |

| Prototyping | 1–6 Weeks | Factory creates sample based on specs. |

| Internal QC | During Production | Raw material, in-line, and final checks. |

| Persetujuan Sampel | Final Week | Brand signs off on the prototype. |

A fully custom makeup brush sample can be developed and delivered in under a week.False

This is highly unrealistic for a truly custom (OEM) design. While simple modifications (ODM) can be faster, custom tooling, material sourcing, and assembly for a new brush typically take 3-6 weeks.

Top-tier cosmetic brush OEMs often report QC qualification rates above 99%.True

This is a known industry benchmark. Factories that service prestige brands maintain extremely high pass rates through rigorous multi-stage quality control processes to minimize defects.

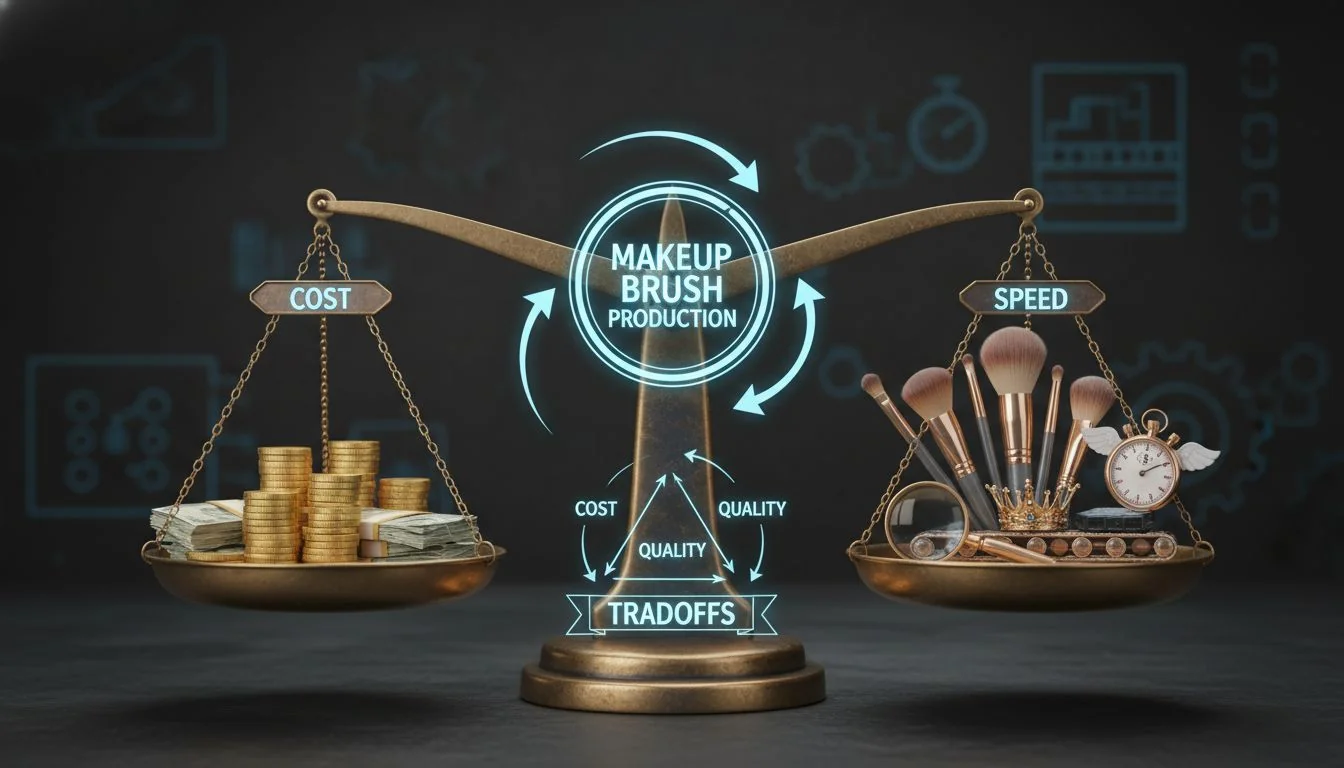

What Does This Mean for Your Brand: Cost, MOQ, and Speed Tradeoffs When Replicating Hermès-Level Sampling?

You want that Hermès-level quality, but the perceived costs and minimum order quantities (MOQs) feel impossible for an indie brand. You can achieve it by making smart, strategic tradeoffs.

Replicating luxury quality means balancing cost, MOQ, and speed. Artisan natural hair is slow and expensive. High-performance synthetics from a certified OEM offer a faster, more consistent, and cost-effective path to luxury.

You don’t need Hermès’ budget to create an exceptional brush. You just need their strategic mindset. For an independent brand founder like you, this means understanding the tradeoffs and choosing a manufacturing partner who can deliver on your specific needs. This is where we focus our energy at Brushino—making luxury-level customization accessible. Instead of chasing an exact replica of a $126 goat hair brush, you can create your own signature tool by making informed choices.

Making Smart Tradeoffs

- Cost & Materials: Natural hair is expensive and its quality can vary. A high-performance, cruelty-free synthetic fiber can deliver 95% of the softness and better durability at a fraction of the cost. Likewise, a weighted aluminum ferrule can feel just as premium as brass to most users.

- MOQ & Scalability: Artisan workshops in France have very high MOQs and limited capacity. A flexible OEM partner can offer low MOQs for your launch, allowing you to test the market without overstocking, and then scale with you as you grow.

- Speed & Simplicity: The fastest path to market is often a customized ODM brush. By choosing from a supplier’s existing handle shapes and customizing the fibers, color, and logo, you can get to market in weeks, not months.

| Factor | High-Cost Approach (Artisan) | Smart-Tradeoff Approach (OEM) | Benefit for Indie Brands |

|---|---|---|---|

| Hair | Natural Goat Hair | Premium Synthetic Fiber | Lower cost, cruelty-free, consistent |

| MOQ | 10,000+ units | 500-1,000 units | Less risk, better cash flow |

| Speed | 3-6 months | 4-8 weeks | Faster to market, capture trends |

Indie brands must order at least 10,000 brushes to get any level of customization.False

This is false. Modern, flexible OEMs like Brushino specialize in low MOQ solutions, often starting at 500 or 1,000 units, to help independent brands launch without massive upfront investment.

Choosing high-performance synthetic fibers can reduce production costs and lead times compared to natural hair.True

This is true. Synthetic fibers are engineered for consistency, are more readily available, and bypass the complex sourcing and processing steps required for natural animal hair, making them faster and more cost-effective.

Conclusion

Achieving luxury-level brush quality is not about a huge budget. It’s about a smart strategy, a detailed brief, and the right manufacturing partner who understands your brand’s vision.

References

-

Exploring the role of French artisans reveals the craftsmanship behind high-end beauty tools. ↩

-

Quality control is vital for luxury brands; knowing the best practices can help maintain high standards. ↩

-

Understanding the dual-sourcing model can help brands leverage both artisanal and industrial strengths for quality. ↩

-

A tech pack is crucial for ensuring that manufacturers meet luxury standards; understanding it can enhance product quality. ↩

-

Discover the benefits of high-grade goat hair in achieving softness and performance in brushes. ↩

-

Understanding the benefits of a brass ferrule can enhance the perceived quality and user experience. ↩