Struggling to spec a winning kabuki brush? Wasting time and money on samples that don’t perform can be frustrating. This guide provides the OEM roadmap to nail your design.

A hexagon kabuki performs best when you match specs to your goal. Use dense, flat-top synthetic fibers1 for liquid coverage. Choose a rounded, medium-density dome for powder. Design the handle with 22–26 mm across-flats and a matte finish to improve grip and prevent rolling.

Getting a product like a kabuki brush right isn’t just about looks. It’s about translating what a customer wants—like a "flawless finish"—into technical specifications that a factory can actually produce. I’ve seen many projects get stuck in this translation phase. It’s where good ideas either become great products or costly failures. In my years of running a trading company, I learned that the secret is in the details of the spec sheet. This guide breaks down those details, from the fibers in the brush head to the box it ships in, so you can move from concept to production with confidence.

Hexagon handles are becoming more common for liquid foundation kabuki brushes.True

Their anti-roll and improved grip features have confirmed their market viability and appeal to consumers and pro makeup artists.

Natural hair is always better than synthetic for all types of makeup.False

While natural hair is great for powders, premium synthetic fibers (like PBT or PTT) are superior for liquids as they don't absorb product, are easier to clean, and provide a streak-free finish.

How do you engineer the brush head for the perfect powder or liquid finish?

Your brush design looks great, but it applies makeup poorly. This leads to bad reviews and lost sales. The key is engineering the head for a specific formula and desired finish.

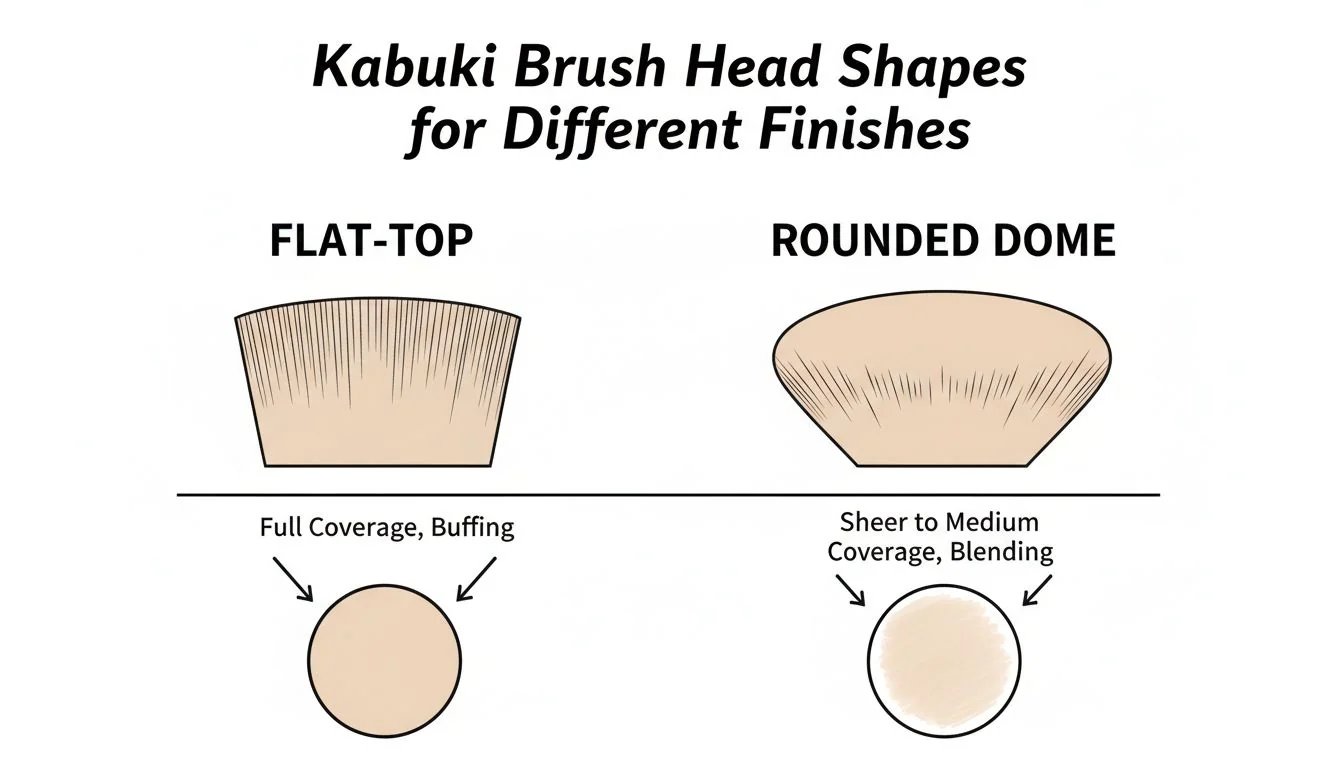

For liquids, use a dense, flat-top head with fine synthetic fibers (0.06–0.07 mm denier) for full coverage. For powders, a less dense, rounded dome with slightly thicker fibers (0.07–0.09 mm) provides a soft, diffused application. This finish-first approach ensures performance.

The performance of a kabuki brush starts and ends with the head. You can’t use the same design for a loose setting powder and a full-coverage liquid foundation and expect great results from both. I call this "finish-first engineering2." You decide on the makeup formula and desired look first, then you build the specs around that goal. This simple shift in thinking saves countless hours and reduces sampling rounds.

The Finish-First Matrix: Powder vs. Liquid

For liquid and cream formulas, the goal is to buff and blend without absorbing the product into the bristles. This requires a surface that can move product around, not soak it up. For powders, the goal is pickup and diffusion. The brush needs to grab the right amount of powder and distribute it evenly for a soft, airbrushed look. These two functions demand different engineering.

Translating Finish to Specs

This is where you, the designer, translate consumer language into a manufacturer’s spec sheet. "Streak-free" means a dense, flat-top bundle of fine fibers. "Airbrushed" means a fluffier, rounded dome with medium density.

| Parameter | Liquid/Cream Foundation (Full Coverage) | Powder/Bronzer (Sheer/Medium) |

|---|---|---|

| Head Shape | Flat-Top | Rounded Dome |

| Fiber Type | Premium Synthetic (PBT/PTT) | Premium Synthetic or Natural Hair |

| fiber denier3 | 0.06–0.07 mm | 0.07–0.09 mm |

| Bundle Density | High (45k–52k fibers) | Medium (38k–42k fibers) |

| Loft Height | 28–35 mm | 35–45 mm |

| Head Diameter | 25–30 mm | 28–35 mm |

A lower fiber denier (e.g., 0.06 mm) is generally better for applying liquid foundation.True

Finer fibers, when packed densely, create a smooth surface that buffs liquid makeup without absorbing it, preventing streaks and product waste.

A higher bundle density is always better for a kabuki brush.False

While high density is great for full-coverage liquids, a medium or lower density is better for powders, as it allows for better pickup and a more diffused, airbrushed application.

What makes a hexagon handle feel premium and prevent rolling?

A beautiful brush that rolls off the vanity is an instant frustration. This small detail can make a premium product feel cheap and impractical. A well-designed hexagon handle solves both problems.

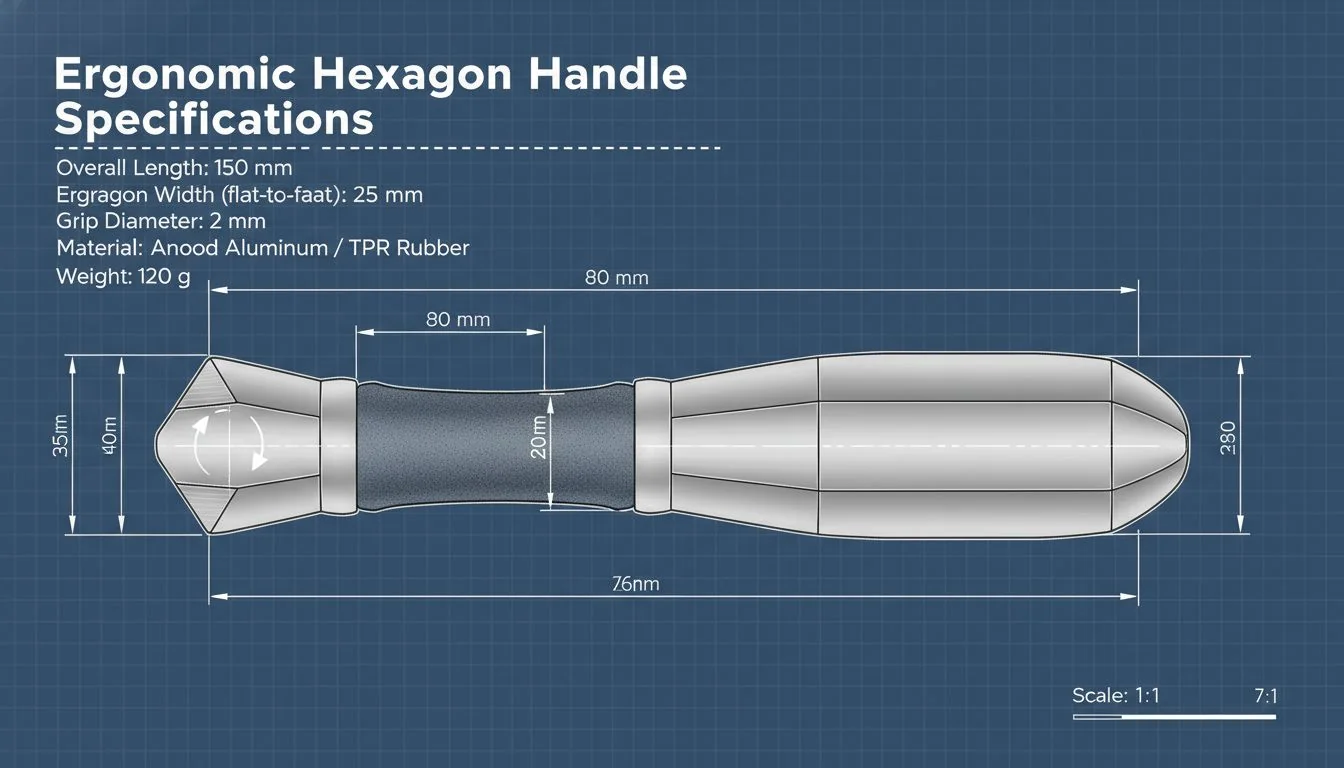

A hexagon handle with 22–26 mm across-flats, soft 1.0–1.5 mm edge radii, and a matte finish provides excellent grip and stops rolling. Placing the center-of-mass 35–45 mm from the base ensures it feels balanced in the hand during use, enhancing the premium feel.

The handle is the primary interface between the user and the tool. Its ergonomics define the user’s control and the product’s perceived quality. The hexagon shape is brilliant because it solves two common problems at once: stability and control. I’ve seen brands gain a real market edge by focusing on these ergonomic details.

The Anti-Roll Advantage

This is the most obvious benefit. A six-sided handle won’t roll off a desk, vanity, or makeup artist’s station. This is not a small detail; it’s a major functional improvement that customers notice immediately. It shows that the designer thought about how the product would be used in real life.

Key Ergonomic Specifications

Beyond just being a hexagon, the specific dimensions are what create a premium feel. A handle that’s too small or has sharp edges feels cheap and is uncomfortable to use. A poorly balanced handle causes fatigue. Getting these specs right is crucial for a high-quality product.

| Parameter | Recommended Spec | Rationale |

|---|---|---|

| Across-Flats | 22–26 mm | Provides a substantial, comfortable grip for buffing. |

| Facet Edge Radii | 1.0–1.5 mm | Softens edges to avoid pressure points during use. |

| Center of Mass | 35–45 mm from base | Creates a balanced feel, improving control and reducing fatigue. |

| Finish | Matte (Soft-touch, bead-blasted) | Increases friction for a secure grip without being sticky. |

A matte finish on a brush handle improves grip.True

Finishes like soft-touch PU paint or bead-blasted aluminum increase the coefficient of friction, providing a secure grip without feeling sticky, which is crucial for precise makeup application.

The weight of the handle doesn't affect the brush's performance.False

The handle's weight and center-of-mass are critical for balance. A well-balanced brush (center-of-mass 35-45mm above the base) reduces fatigue and allows for more controlled buffing motions.

How do you specify the ferrule and assembly to prevent shedding and wobble?

Nothing kills brand trust faster than a brush that sheds or wobbles. Customers see it as a sign of poor quality, leading to returns. Specifying tight assembly tolerances is non-negotiable.

To prevent shedding and ensure durability, specify a ferrule inner diameter4 (I.D.) tolerance of ±0.05 mm. Also, mandate a glue line depth greater than 10 mm. These two specs are critical for a secure bond between the handle, ferrule, and fiber bundle.

This is an area where I’ve seen many brands try to cut corners, and it almost always backfires. The ferrule and the glue that holds everything together are the structural core of the brush. If this assembly fails, the entire product fails. A wobbly head or shedding bristles are not just annoyances; they are signs of a fundamental manufacturing defect. As a designer, your spec sheet is your only defense against this.

Why Tolerances Matter

The ferrule is the metal collar that connects the handle to the brush head. The fit between the fiber bundle, the ferrule, and the handle must be precise. If the ferrule’s inner diameter is too large, the bundle will be loose. If it’s too small, assembly becomes difficult and can damage the fibers. A tolerance of ±0.05 mm is strict, but it’s what separates a professional-grade tool from a disposable one.

The Critical Role of Glue

The glue is the unsung hero. You need to specify not just the type of adhesive but also how it’s applied. A deep glue line (over 10 mm) ensures that a significant portion of the fiber bundle is encased in the adhesive, creating a strong mechanical bond that can withstand repeated use and washing. A shallow glue line is a common point of failure.

Specifying a glue line depth of over 10 mm helps prevent brush shedding.True

A deeper glue well ensures a larger surface area of the fiber bundle is securely bonded within the ferrule, making it highly resistant to pulling out during use and washing.

The material of the ferrule is purely for aesthetics.False

While aesthetics are important, ferrule material (e.g., aluminum vs. brass) also affects weight, durability, and corrosion resistance. The choice impacts the brush's overall balance and longevity.

Which packaging should you choose based on cost, retail channel, and sustainability?

Your brush is perfect, but the packaging is an afterthought. This can lead to damaged products, high costs, or missed retail opportunities. Your packaging must be designed for your specific sales channel.

For mass retail, use an FSC paper box with a window and EPE tray (5–15% of retail price). For luxury, a PU canister or bag (up to 30% cost share) enhances value. Always consider channel-specific compliance, like EU recyclability rules, and sustainability trends.

Packaging is your product’s first impression and its last line of defense. I’ve seen amazing products fail because the packaging didn’t align with the brand’s price point or the logistics of the sales channel. You have to balance cost, protection, perceived value, and compliance. It’s a complex decision, but breaking it down by channel makes it much easier.

Matching Packaging to Retail Channel

An e-commerce product needs more robust protection against shock than a product sitting on a retail shelf. A luxury product needs an unboxing experience that justifies its price.

Balancing Cost and Perceived Value

Packaging cost is a significant part of your Bill of Materials (BOM). For mainstream products, it typically ranges from 5-15% of the retail price. For luxury goods, it can easily exceed 30%. You must use this as a benchmark to back-calculate your target costs.

Navigating Sustainability and Compliance

Sustainability is no longer optional. Consumers demand it, and regulations like those in the EU enforce it. Materials like FSC-certified paper, recyclable PET, and EVA are good starting points. Always check the specific rules for your target markets.

| Channel | Cost Share (% of Retail) | Recommended Packaging | Key Considerations |

|---|---|---|---|

| Mass Retail | 5–15% | FSC paper box with PET window, EPE/paper tray | Visibility, protection, hang-tab compatibility. |

| E-commerce | 8–18% | Sturdy box with protective inserts (EPE, molded pulp) | Shock absorption, minimal size/weight for shipping. |

| Premium/Luxury | 20–30%+ | PU/metal canister, PU pouch with velvet lining | Unboxing experience, perceived value, reusability. |

Packaging can account for over 30% of the retail price for a luxury cosmetic brush.True

In the luxury market, the unboxing experience is part of the product. Premium materials like metal canisters, velvet linings, and intricate designs contribute significantly to the cost but also drive perceived value and brand image.

An FSC-certified paper box is the most sustainable option in all cases.False

While FSC paper is a great choice, sustainability is complex. A reusable PU pouch or a highly recyclable PET canister might have a better lifecycle assessment depending on consumer behavior and local recycling infrastructure.

Conclusion

Mastering your kabuki brush design means aligning every spec—from fiber denier to packaging choice—with your formula, brand, and channel. This detailed approach reduces risk and ensures a successful product.

References

-

Learn about the advantages of synthetic fibers over natural hair for liquid makeup applications. ↩

-

Discover how finish-first engineering can improve makeup application and product performance. ↩

-

Explore how fiber denier impacts the performance of kabuki brushes for different makeup types. ↩

-

Understand the importance of ferrule specifications in preventing shedding and ensuring durability. ↩