Your brand wants a concealer brush that customers love, but getting the feel and performance right is tough. You’re stuck trying to explain a "soft, blurring" effect to a factory.

To create a Real Techniques-style concealer brush, specify a soft, domed “kitten-paw” head1 with dense vegan taklon fibers (≈0.07–0.10 denier). Use a seamless aluminum or brass ferrule and mandate QC tests for streak-free coverage, low shedding, and durability through weekly cleanings.

Up to 50% of adult women experience acne at some point, making spot-concealing precision a key feature for makeup brushes.True

This data from dermatological studies highlights a significant consumer need that a well-designed concealer brush can address.

All synthetic brush fibers are made from the same type of plastic.False

Synthetic fibers can be made from various polymers, including Taklon (a type of polyester) and Nylon, each with different properties of softness, durability, and liquid absorption.

In my years of helping clients turn ideas into physical products, I’ve learned one key lesson: success is in the details. It’s not enough to show a factory a popular product and say, "make this." You have to provide a precise blueprint. Let’s break down how to do this using a high-performance concealer brush as our example. This process is the same whether you’re making electronics or cosmetics—it’s about translating user experience into engineering specifications.

How does shape engineering like a “kitten-paw” or dome lift under-eyes and blur edges?

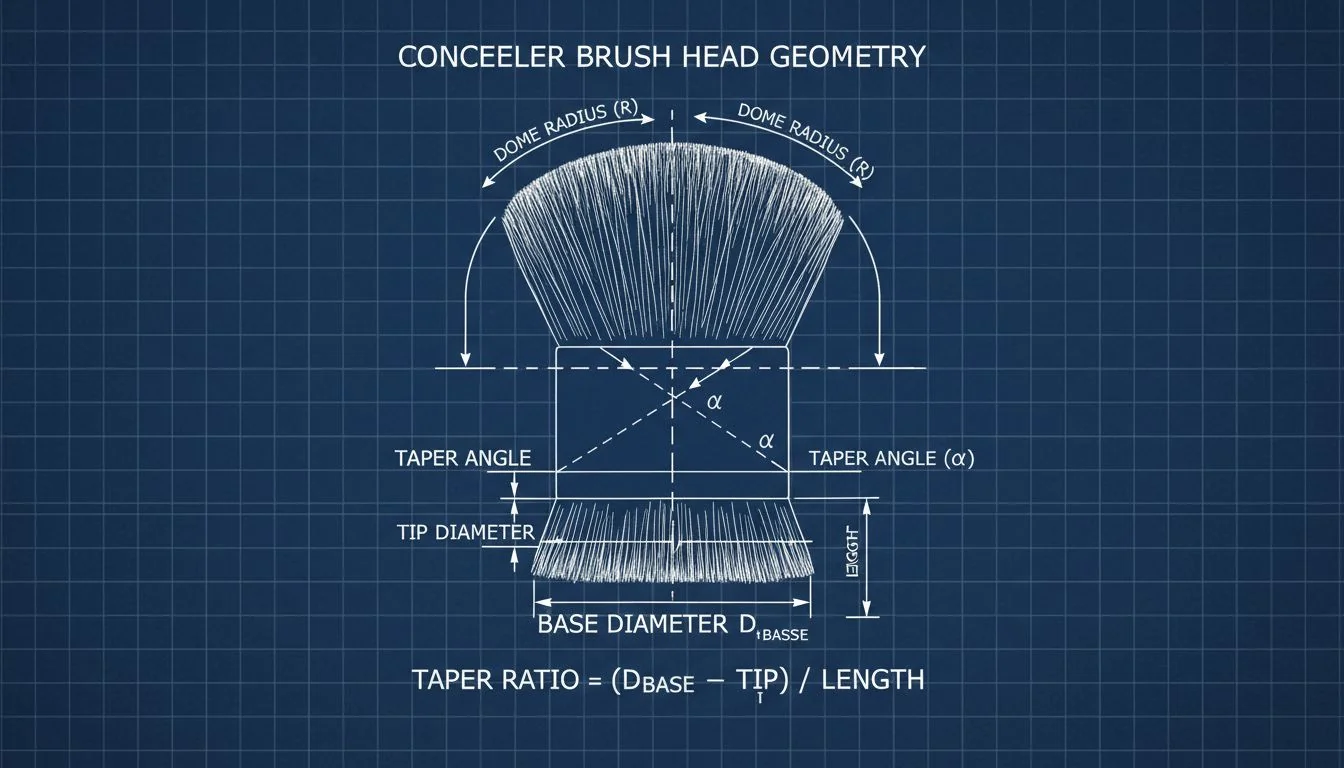

You see terms like "kitten-paw" and know they sell, but you can’t put that on a technical drawing. The real challenge is turning that marketing language into measurable geometry for your manufacturer.

A brush’s shape directly controls its function. Domed or "kitten-paw" geometries are popular because their curved surface hugs the contours under the eye. This design allows for both patting and sweeping motions without leaving harsh lines, effectively blurring concealer into the skin for a natural finish.

To get this right, you need to move beyond vague descriptions. I always tell my clients to specify the exact geometry. This is how you ensure consistency from the first sample to the 10,000th unit. For a concealer brush, you need to define the key parameters that create that "blurring" effect. Think about the Dome Radius2, the softness of the edges, and the overall density. An angled head, for example, offers a different kind of precision for spot concealing. Your spec sheet is your primary tool for quality control.

Key Geometric Specifications

| Parameter | Specification Range | Purpose |

|---|---|---|

| Dome Radius | 12–16 mm | Matches the natural curve of the under-eye area for ergonomic application. |

| Head Shape | Domed, Kitten-Paw, or Angled | Domed for blurring, Angled (e.g., 40°) for sharp precision on blemishes. |

| Edge Taper Ratio | High Taper | Creates softer, feathered edges to prevent streaks and lines during blending. |

| Head Thickness | 8–12 mm | Provides enough body for effective patting and stippling without being too stiff. |

A brush with an angled head, like some Pat McGrath designs, improves precision for spot concealing.True

The 40° slant on certain high-end brushes allows the user to place product precisely on small blemishes without disturbing the surrounding makeup.

The shape of a makeup brush head has no impact on its performance.False

The geometry of the brush head is critical; it determines how the brush picks up, deposits, and blends product, and how it fits the contours of the face.

What does fiber science for concealer brushes really involve?

Your customers want a brush that feels luxuriously soft but also provides perfect coverage. You know "vegan" is a great selling point, but the fiber’s technical specs are what actually deliver the performance.

fiber science for concealer brushes3 centers on using non-porous synthetic fibers like Taklon or Nylon. These materials don’t absorb liquid or cream products, ensuring more concealer gets onto the skin. The key is specifying the denier (fiber thickness), density, and tip finishing to control coverage and softness.

When I work on a new project, we get deep into the material science. For a concealer brush, you want ultra-fine fibers to ensure a soft feel on the delicate under-eye skin. A denier of 0.07 to 0.10 is a good target. But softness is only half the story. The density of the fiber bundle4 is what determines the level of coverage. A denser brush will pack on more product for full coverage, while a less dense brush gives a sheerer, more airbrushed finish. You also need to specify the tip treatment—are the fibers mechanically tapered, or are they polished? This small detail makes a huge difference in how the brush feels and performs. It’s this level of detail that separates an average product from a great one.

Fiber Specification Checklist

- Material: Specify 100% vegan synthetic fibers, such as PBT (Taklon) or Nylon. They are hygienic and ideal for cream/liquid formulas.

- Denier: Target a range of 0.07–0.10 for an optimal balance of softness and structure.

- Density (Bundle Count): Define the number of bristles. Higher counts lead to more coverage. This is a critical variable to test during sampling.

- Tip Finishing: Request polished or extruded-tapered tips for the softest feel and to prevent any scratchiness on the skin.

- Crimping: Specify whether fibers should be straight or crimped. Crimping adds texture and volume, which helps with powder pickup but can be useful for blending creams, too.

Synthetic brush fibers are better for liquid and cream concealers.True

Their non-porous surface prevents them from absorbing product, leading to less waste and a smoother application. They are also easier to clean and more hygienic than natural hair.

Denser brushes always provide a more natural, sheer finish.False

The opposite is true. Denser brushes pick up and deposit more product, which results in fuller, more opaque coverage. A less dense brush is better for a sheer finish.

What are the key decisions for the ferrule and handle?

A brush that looks good but feels unbalanced or breaks after a few washes will kill your brand’s reputation. The ferrule and handle are not just for looks; they are critical for durability and user experience.

The key decisions involve material choice, construction, and balance. For the ferrule, you can choose lightweight, color-anodized aluminum or stronger, more premium seamless brass. For the handle, the balance point is crucial for control and a professional feel during application.

I’ve seen too many brands focus only on the brush head and forget the rest. The handle and ferrule are what the user holds. They are the foundation of the tool. You need to specify the ferrule material—is it aluminum (like Al6063) for lightweight color-coding, or is it nickel-plated brass for superior strength and a premium weight? You must also demand a seamless ferrule to prevent it from splitting. The adhesive is just as important. I always specify a high-grade epoxy and a minimum pull-out strength test (at least 6 kgf) to ensure the head never separates from the handle. Finally, think about balance. The center of mass should be 35–45% of the way from the head, making the brush feel like a natural extension of the user’s hand. These are the details that create a high-quality tool.

Ferrule & Handle Specification Table

| Component | Material/Spec | Benefit |

|---|---|---|

| Ferrule Material | Anodized Aluminum (Al6063) | Lightweight, corrosion-resistant, easy to color-code. |

| Nickel-Plated Brass | Heavier, premium feel, maximum strength and durability. | |

| Ferrule Construction | Seamless | Prevents splitting and water damage to the adhesive. |

| Adhesive | two-part epoxy5 | Provides a strong, waterproof bond between the head and handle. |

| Handle Balance | Center of Mass at 35-45% from Head | Ergonomic design that provides control and reduces hand fatigue. |

| Handle Finish | Matte, Gloss, Soft-Touch | Brandable finishes that enhance grip and aesthetic appeal. |

Seamless brass ferrules are stronger and more durable than standard aluminum ferrules.True

Brass is a stronger alloy than aluminum, and the seamless construction prevents weak points, making it less likely to bend, split, or corrode over time.

The balance point of a makeup brush handle does not affect its usability.False

A well-balanced handle, with its center of mass closer to the ferrule, provides better control and precision, making application easier and more professional.

How can you establish QC tests that prove a streak-free, hygienic application?

You can design the perfect brush, but how do you prove its quality to B2B buyers and end-users? You need objective, repeatable tests that confirm the brush performs as promised, every time.

Establish a five-part QC protocol that quantifies performance. This includes testing for coverage uniformity, streaking, product pickup/laydown ratio, softness, and durability. These tests turn subjective qualities like "good blending" into hard data.

In manufacturing, if you can’t measure it, you can’t control it. That’s why I insist on a clear QC plan. For a concealer brush, we need to codify what "high-performance" means. First, test coverage uniformity on synthetic skin, aiming for a coefficient of variation (CV) under 10%. Second, measure streaking on a tinted gel, with a target index below 0.15. Third, calculate the pickup-to-laydown ratio to ensure the brush efficiently transfers product—a ratio of 0.6 to 0.8 is excellent for creams. Fourth, use a panel to get a perceived softness score6, aiming for 4.5 out of 5 or higher. Finally, test durability with 50 wash cycles (checking for shedding of less than 3%) and a ferrule pull test of at least 6 kgf. This data proves your brush is streak-free, hygienic (by being washable), and built to last. It’s your guarantee of quality.

The 5 Essential QC Tests

- Coverage Uniformity: Apply concealer to synthetic skin. Use a colorimeter to measure consistency. Target: CV ≤10%.

- Streak Index: Swipe the brush on a tinted gel surface. Analyze the image for streaks. Target: ≤0.15 normalized units.

- Pickup/Laydown Ratio: Weigh the brush before and after picking up product, and again after application. Target: 0.6–0.8 for cream concealer.

- Softness Score: Use a blind-test panel to rate the softness of the brush on the skin. Target: ≥4.5/5.

- Durability Test: Subject the brush to 50 automated wash-and-dry cycles and perform a ferrule pull test. Target: ≤3% bristle shed & ≥6 kgf pull strength.

The American Academy of Dermatology recommends cleaning makeup brushes every 7–10 days.True

This regular cleaning cadence helps to remove built-up product, oil, and bacteria, reducing the risk of skin irritation and infections.

Washing a makeup brush once a year is sufficient for hygiene.False

Infrequent washing allows harmful bacteria, oil, and dead skin cells to accumulate, which can lead to acne, skin irritation, and even serious infections.

Conclusion

By translating popular features into precise engineering specs and backing them with rigorous QC tests, you can create a concealer brush that delivers consistent, high-end performance for your brand.

References

-

Understanding this design can enhance your product’s effectiveness in blending and application. ↩

-

Explore how this specification influences application and blending techniques. ↩

-

Delve into the materials that enhance brush performance and user satisfaction. ↩

-

Understanding this can help you choose the right brush for coverage needs. ↩

-

Learn why adhesive quality is crucial for brush durability and performance. ↩

-

Understanding this metric can help you assess brush comfort and effectiveness. ↩