Sourcing custom brushes1 feels like a black box. You worry about inconsistent quality, surprise delays, and getting the right materials. I will show you exactly how it’s done.

Makeup brushes are made through a multi-step process. It starts with weighing and combing fibers, which are then shaped, tied, and glued into a metal ferrule. This assembly is then attached to a finished handle. Factories test for shedding, strength, and material safety to ensure quality.

When I first started on the factory floor, I was amazed by how many hands touch a single brush before it’s ready. It’s not just an automated process; it’s a craft. For brand founders like you, understanding this process is the key to avoiding costly mistakes and getting the exact product you envision. It’s the difference between feeling powerless and being in control of your production. Let’s walk through the journey from raw material to the finished tool in your customer’s hand.

The global market for makeup brushes and tools is expected to grow from USD 7.0 billion in 2024 to USD 12.9 billion by 2034.True

Market analysis reports from firms like Future Market Insights project a compound annual growth rate (CAGR) of around 6.3%, indicating sustained demand for quality beauty tools.

All makeup brushes are mass-produced entirely by machines.False

While some steps are automated, critical stages like fiber shaping, combing, and final assembly for high-quality brushes are still done by hand by skilled workers to ensure precision and softness.

How are makeup brushes made step by step?

You’ve approved the perfect sample, but how do you know the bulk order will be the same? This uncertainty is stressful. Let’s walk through the factory floor together, step-by-step.

A makeup brush is made in a sequence: fibers are weighed, combed, and aligned. Then, they are wired into a tuft, shaped, and glued into a ferrule. This head is assembled onto a handle, and the final brush is cleaned and inspected before packing.

I’ve seen every part of this process thousands of times. It’s a blend of precision and artistry. Knowing these steps helps you ask your supplier the right questions and specify the quality checkpoints that matter most. This is how you ensure your final product is something you’re proud to put your name on.

From Raw Fibers to a Perfect Tuft

The heart of the brush is the tuft, and its creation is incredibly detailed. It’s not just a bundle of hair.

- Bristle Weighing & Combing: It starts with weighing the fibers to the milligram. This controls the brush’s final density. Then, workers meticulously comb the fibers by hand to remove any tangles or misaligned strands and ensure they all face the same direction.

- Alignment & Wiring: The combed fibers are placed into a mold to get the basic shape. A wire is then tightly tied around the base to hold the tuft together. The tension of this wire is critical to prevent shedding later.

- Shaping & Trimming: For high-end brushes, the shape is created by tapping the fibers into a shaper, not by cutting. This keeps the natural, soft tips of the fibers intact. Any stray fibers are then carefully trimmed or shaved from the sides, a step often called "pulling" or "deflashing."

Assembly and Finishing Touches

Once the tuft is ready, it becomes a complete brush.

- adhesive dosing2: A precise amount of specialized adhesive is dispensed into the metal ferrule. Too little glue causes shedding; too much can make the brush stiff.

- Assembly: The tuft is inserted into the ferrule, which is then crimped onto the finished handle. The alignment here must be perfect for a professional look and feel.

- Cleaning & Final QC: The finished brush is cleaned to remove any loose fibers or dust from the manufacturing process. Finally, it goes through a last round of quality checks before being packaged for shipment.

Hand-shaping a brush head preserves the soft, tapered tips of the fibers, resulting in a much softer feel on the skin.True

Cutting fibers creates blunt, sharp ends, which can feel scratchy. Hand-shaping in a mold ensures the natural, delicate tips form the application surface, which is a hallmark of a high-quality brush.

The amount of glue used in a brush doesn't affect its performance.False

Incorrect adhesive dosing is a primary cause of brush failure. Insufficient glue leads to shedding, while excessive glue can wick up into the bristles, making the tuft stiff and reducing its ability to blend makeup properly.

What materials are used in professional makeup brushes?

Choosing materials feels overwhelming. The wrong fiber can ruin your brush’s performance, and a cheap handle can damage your brand’s premium image. I’ll break down what pros actually use.

Professional brushes typically use high-performance synthetic fibers3 like PBT, often called "taklon." Ferrules are made of lightweight aluminum or premium-feel brass. Handles are crafted from wood (including FSC-certified options), bamboo, or durable bio-resins.

The materials you choose define your brush’s performance, cost, and story. As a brand founder, you need to balance aesthetics, function, and your brand values, like being cruelty-free. I help clients navigate these choices every day to find the perfect combination for their audience and budget.

Synthetic vs. Natural Bristles: Performance and Compliance

The debate between synthetic and natural hair is over for most modern brands. Advanced synthetic fibers made from PBT or nylon now offer superior performance and consistency. They can be engineered with specific diameters, crimping, and tapered tips to mimic the texture of natural hair for powder pickup, but they excel with cream and liquid products. Most importantly, they are 100% cruelty-free, which is a non-negotiable for many consumers today.

Ferrule and Handle Choices That Affect Durability and Cost

The ferrule and handle are not just for looks; they determine the brush’s balance and longevity.

| Component | Material Options | Key Considerations |

|---|---|---|

| Ferrule | Aluminum | Lightweight, rust-proof, cost-effective. The most common choice. |

| Brass | Heavier, provides a premium weight and feel. More durable crimp. | |

| Handle | Wood (Birch, Ash) | Classic feel, can be painted in any color. Look for FSC-certified options. |

| Bamboo | Lightweight and a visible symbol of sustainability. | |

| Resins (ABS, PLA) | Durable, can be molded into unique shapes. Recycled or bio-based options are available. |

Sustainability Options: Vegan Fibers, FSC Wood, and More

Sustainability is no longer a niche request; it’s a core requirement. You can build a more responsible product by choosing:

- Vegan Fibers: All-synthetic tufts are the standard for ethical beauty.

- FSC-Certified Handles: Guarantees the wood comes from responsibly managed forests.

- Recycled Materials: Ferrules can be made from recycled aluminum, and handles from recycled resins.

- Ferrule-less Designs: Some brushes are now made with the tuft inserted directly into a wooden handle, reducing metal use.

Modern synthetic bristles are just as good as natural hair for applying powder makeup.True

Advanced PBT fibers with textured surfaces and tapered tips are engineered to pick up and diffuse powder just as effectively as natural hair, while also offering the benefits of being vegan, more durable, and easier to clean.

Brass ferrules are always better than aluminum ferrules.False

While brass is denser and feels more luxurious, a well-made, thick-gauge aluminum ferrule can be just as durable. The quality of the crimping and adhesive is often more important for longevity than the metal itself.

How do factories test brush quality (QC) before shipment?

You approved a beautiful sample, but you’re worried the 5,000-piece bulk order won’t live up to it. This is a common fear. Here are the tests a reliable factory performs to guarantee consistency.

Factories conduct a series of quality control (QC) tests. These include tuft pull tests for shedding, ferrule torque tests for looseness, and cross-hatch tests for paint adhesion on the handle. They also verify dimensions, color, and material compliance.

When I set up my own factory, I built our QC process around preventing the most common client complaints. A good supplier shouldn’t just inspect for defects at the end; they should have checkpoints at every single stage of production. You should insist on seeing the reports from these tests.

Quality Control Tests Buyers Should Require

Don’t just hope for the best. Add these tests to your quality specification sheet.

| Test | Purpose | Acceptance Criteria (Example) |

|---|---|---|

| tuft pull test4 | Measures how well the tuft is secured in the ferrule. | No more than 5-10 fibers lost on a 500g pull. |

| Shedding Test | Checks for loose fibers before and after washing. | No more than 3-5 fibers shed after 3 wash/dry cycles. |

| Ferrule Torque Test | Ensures the ferrule won’t twist or detach from the handle. | Ferrule must withstand a specific rotational force without moving. |

| Handle Coating Adhesion | Checks if the paint or lacquer will chip or peel. | No paint removal on a cross-hatch tape test. |

| Dimensional Checks | Verifies length, diameter, and tuft shape against the spec. | Must be within +/- 0.5mm of the approved sample. |

Controlling Common Failures

Most brush returns come from three problems: shedding, a loose ferrule, or chipping paint. Here’s how we control them:

- Shedding: We prevent this with precise adhesive dosing, proper curing time, and strong wire-tying. We also pre-wash brushes to catch any loose fibers before they are packed.

- Loose Ferrules: This is solved by validating the crimping pressure and using a high-quality adhesive between the handle and ferrule.

- Paint Chips: We use durable, multi-layer coatings and test adhesion rigorously.

Brush shedding is random and cannot be prevented.False

Shedding is almost always caused by a controllable manufacturing defect, such as insufficient adhesive, improper curing, or a weak wire tie at the base of the tuft. Strict process controls can nearly eliminate it.

A simple visual check is enough to guarantee brush quality.False

Visual checks can't detect underlying issues like poor adhesive bonding or weak paint adhesion. Physical tests like pull tests and torque tests are essential to ensure a brush's long-term durability.

What are typical OEM MOQs and lead time considerations?

You’re an ambitious indie brand, but high Minimum Order Quantities (MOQs) feel like a wall. You’re forced to either over-invest or abandon your custom design. Let’s talk about what’s realistic.

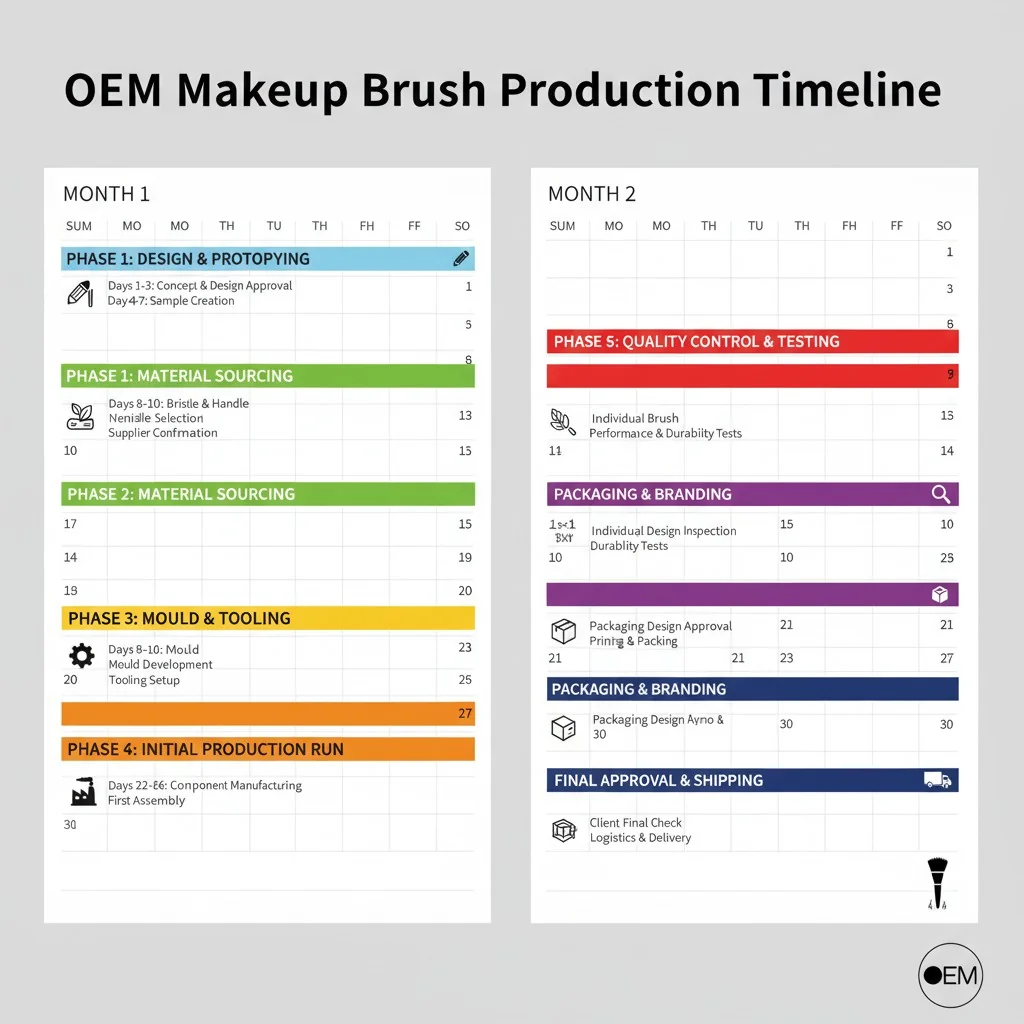

MOQs depend on customization. Standard catalog items may have flexible MOQs, but fully custom brushes often require 1,000 to 5,000 pieces per style. Lead times of 45-75 days are typical, driven by material sourcing and finishing processes.

I started Brushino specifically to help founders like you. Many factories don’t want to bother with smaller, custom projects. We see it as a partnership. We offer lower MOQs because I know that helping you launch successfully means you’ll grow with us. Understanding the factors that drive costs and timelines allows you to plan a smarter, more profitable launch.

Understanding MOQs: Standard vs. Custom

Not all MOQs are the same.

- Standard Items: If you choose a brush from a supplier’s existing catalog and only add your logo, MOQs can be much more flexible, sometimes as low as 500 pieces.

- Custom Projects (ODM): If you require a unique handle shape, ferrule color, or a custom-blended fiber, the MOQ will be higher. This is because factories have to order raw materials in bulk and set up new tooling. For these, 1,000 to 5,000 pieces is a common starting point.

What Drives Lead Times and Costs?

Knowing this helps you manage your launch calendar and budget.

- Lead Time Drivers:

- Fiber Sourcing: Speciality or custom-colored fibers can take weeks to procure.

- Tooling: Creating a new mold for a custom handle or ferrule adds time.

- Handle Finishing: Multi-layer paint, soft-touch coatings, or detailed logos require more steps and drying time.

- Cost Drivers:

- Fiber: The grade, density, and complexity of the fiber blend is the biggest cost factor.

- Handle: The material (e.g., FSC wood vs. plastic) and finish (e.g., high-gloss vs. matte) significantly impact price.

- Labor: Intricate, hand-shaped tufts require more skilled labor and are more expensive than simple, machine-cut shapes.

The only way to get custom brushes is to order 10,000 pieces or more.False

Many modern OEM/ODM suppliers, especially those focused on supporting indie brands, offer much lower MOQs for custom projects, often starting in the 1,000-3,000 piece range, depending on the complexity.

The brush handle has little impact on the total cost.False

The handle is a major cost driver. A complex shape, a premium material like FSC-certified wood, or a multi-layer, high-gloss finish can significantly increase the unit cost compared to a simple plastic handle.

Conclusion

Understanding how a makeup brush is made gives you control. You can now brief suppliers with confidence, specify the quality you need, and build the lasting brand you envision.

References

-

Understand the complexities and considerations involved in sourcing custom makeup brushes for your brand. ↩

-

Find out how the right amount of adhesive can prevent common issues like shedding and ensure brush longevity. ↩

-

Discover why synthetic fibers are preferred in modern makeup brushes and their advantages over natural hair. ↩

-

Learn about the tuft pull test and its significance in ensuring the durability of makeup brushes. ↩