Worried about hidden toxins in your brushes? Cheap materials can cause irritation and shedding. I’ll show you how to source safe, high-quality tools that protect your customers and brand.

Non‑toxic makeup brushes use safe, compliant materials: synthetic bristles (nylon/PBT), nickel‑plated brass ferrules1, REACH‑compliant epoxy, and low‑VOC finished handles (FSC wood/bamboo). They reduce skin irritation, avoid restricted chemicals, and ensure durable, hygienic application.

The term "non-toxic" gets thrown around a lot in the beauty industry. But for a brand founder like you, it’s not just a marketing buzzword. It’s a promise of safety and quality to your customers. When I first started working on the factory floor, I saw firsthand how a small choice in materials could make a huge difference in the final product. A brush that looks good but causes skin reactions or falls apart is a liability for your brand.

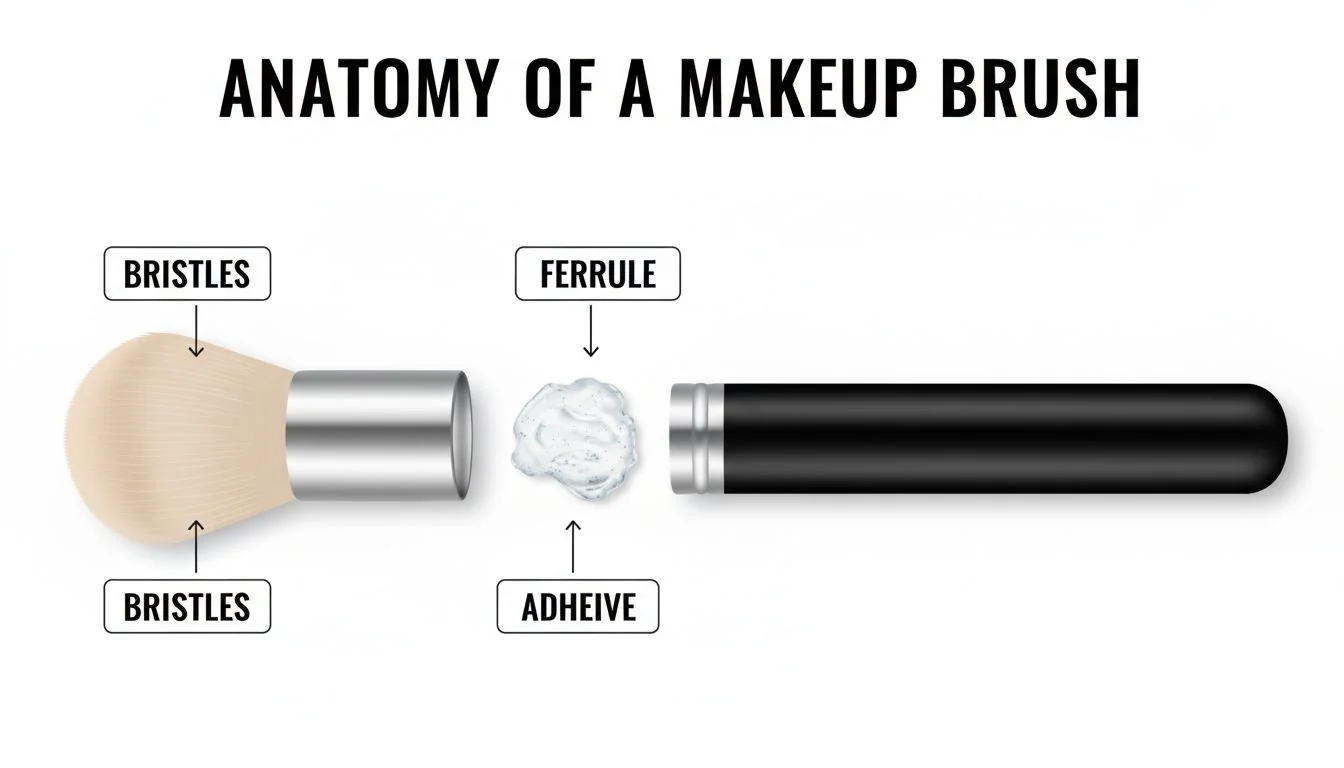

Understanding what goes into a truly non-toxic brush is your best defense. It allows you to ask suppliers the right questions and demand proof, not just promises. Let’s break down exactly what "non-toxic" means for each part of the brush, so you can source with the confidence that you’re delivering a safe, reliable, and beautiful tool.

All synthetic bristles are hypoallergenic.False

While high-quality synthetic fibers like PBT are less likely to cause allergies than natural hair, some individuals can still have sensitivities to the dyes or materials themselves.

REACH is a European Union regulation concerning the Registration, Evaluation, Authorisation and Restriction of Chemicals.True

It aims to protect human health and the environment from chemical risks. Compliance is crucial for brands selling in the EU.

What does “non-toxic” really mean for makeup brushes?

The term "non-toxic" can be confusing. Without clear standards, you risk sourcing low-quality brushes. Let’s define what it means: safe materials, proven compliance, and tested construction.

A non-toxic brush uses inert, compliant materials in its bristles (PBT/nylon), ferrule (nickel-plated brass), adhesive (REACH-compliant epoxy), and handle (FSC wood/bamboo2). The goal is avoiding restricted substances, reducing irritation, and ensuring durability without shedding.

When I started my own factory, I learned that a brush is only as strong as its weakest part. For brand owners, "non-toxic" isn’t a single feature; it’s a system of choices. It means every component is deliberately selected to be inert, safe, and durable. This protects your customers from potential allergens and irritants found in cheaper alternatives. It also protects your brand’s reputation by ensuring the brushes perform well and last long. Think of it as a commitment to quality from the inside out. Here’s a simple breakdown of the four key areas.

The Four Pillars of a Non-Toxic Brush

| Component | Non-Toxic Standard | Why It Matters for Your Brand |

|---|---|---|

| Bristles | Synthetic PBT/PET/Nylon | Inert, low-porosity fibers reduce skin irritation3 and product waste. |

| Ferrule | Nickel-plated Brass/Copper | Resists corrosion and denting, preventing shedding and metal allergies. |

| Adhesive | REACH-compliant Epoxy | Creates a waterproof, solvent-resistant bond without harmful chemicals. |

| Handle/Finish | FSC Wood, Low-VOC Coating | Uses sustainable materials4 and avoids volatile organic compounds (VOCs). |

PFAS chemicals are commonly found in makeup brush bristles.False

PFAS scrutiny is focused on certain cosmetic formulas, not typically the tools. However, brands should ensure all components are free of restricted substances to maintain truthful 'non-toxic' claims.

Low-VOC coatings on brush handles reduce harmful air emissions during manufacturing and are safer for the end-user.True

Volatile Organic Compounds (VOCs) can cause respiratory irritation and other health issues. Specifying low-VOC finishes is a key part of creating a non-toxic product.

From fiber to finish, what materials are inside a non-toxic brush (and what risks should you avoid)?

You know the parts of a brush, but what are they really made of? Choosing the wrong materials leads to shedding, corrosion, and unhappy customers. Let’s look inside.

Prioritize low-porosity PBT/nylon bristles, durable nickel-plated brass ferrules, and two-part epoxy adhesives. For handles, choose FSC wood or recycled materials with low-VOC coatings. Avoid thin aluminum ferrules, poorly dyed fibers that bleed, and non-compliant adhesives.

Every decision in manufacturing has a consequence. I’ve seen brands save a few cents on aluminum ferrules only to face a wave of returns due to shedding. A non-toxic, high-performance brush is about making the right choices at every step. It’s not just about avoiding harmful substances; it’s about building a tool that works beautifully and lasts. Your customer feels the difference, even if they can’t name the specific material. Let’s break down the best-in-class materials versus the common shortcuts you must avoid.

Material Choices: Best Practice vs. Common Risks

| Component | Best Practice (What to Specify) | Risk to Avoid (What to Screen For) |

|---|---|---|

| Bristles | Low-porosity PBT/PET/Nylon; specified taper & polish. | Poorly dyed fibers that bleed color when washed. |

| Ferrule | Nickel-plated brass/copper; double crimping. | Thin, soft aluminum that dents, corrodes, and loosens. |

| Adhesive | Two-part epoxy; REACH/Prop 65 compliant. | Weak glues that fail after contact with cleaning solvents. |

| Handle/Coating | FSC-certified wood; low-VOC, sweat-resistant coating. | Coatings with restricted heavy metals or high VOCs. |

Aluminum ferrules are just as good as brass ferrules.False

Aluminum is softer, lighter, and more prone to denting and corrosion. This can cause the ferrule to loosen over time, leading to bristle shedding.

PBT and PET are types of polyester commonly used for synthetic brush bristles.True

These materials can be engineered with specific textures and tapers to mimic natural hair, and their low moisture absorption makes them ideal for liquid and cream products.

How can you make compliance and QC practical with a simple buyer’s checklist?

Verifying a supplier’s "non-toxic" claims is tough. Trusting their word can lead to disaster when the bulk order arrives. I use a simple checklist for documents and tests.

Ask your supplier for a full tech pack, including material specs and REACH/Prop 65 declarations. Then, run your own tests on samples: shedding, pull strength, water soak, and logo abrasion tests to verify quality and durability before production.

When I work with brand founders, their biggest fear is that the final product won’t match the sample. This is where a practical QC process becomes your best friend. It’s not about being difficult; it’s about being clear. A good supplier will welcome your diligence because it ensures everyone is aligned on the definition of "quality." You need to ask for the right papers and then test the product yourself. This two-step process—document review and physical testing—is the most reliable way to protect your investment and your brand.

Step 1: Collect the Right Documents

Before you even test a sample, ask for the paperwork. A reliable factory will have this ready. Request a full tech pack with material specifications for the fiber, ferrule, adhesive, and handle. Also, ask for a REACH declaration (confirming absence of SVHCs) and a California Prop 65 statement.

Step 2: Run Key Physical Tests

Once you have samples, put them to the test. This is how you confirm the quality for yourself.

| QC Test | Method | Acceptance Criteria |

|---|---|---|

| Shedding Test | 100 firm strokes on a rough card. | ≤ 2 loose fibers per 100 strokes (or your agreed spec). |

| Soak Test | Submerge in water for 24 hours. | No ferrule corrosion, handle swelling, or loosening. |

| Solvent Wash | Clean with makeup remover. | Adhesive remains solid; no dye bleed from bristles. |

| Logo Abrasion | 50-100 firm rubs with a cloth. | Logo remains intact with no visible wear. |

California's Proposition 65 only applies to food products.False

Prop 65 requires businesses to provide warnings about significant exposures to chemicals that cause cancer, birth defects or other reproductive harm. This applies to many consumer goods, including cosmetics and their tools.

A shedding test is a standard QC procedure for makeup brushes.True

It involves stroking the brush a set number of times on a surface to count how many fibers fall out, ensuring the brush meets an agreed-upon quality standard for shedding.

How can you achieve sustainability without greenwashing?

Want sustainable brushes but hate misleading "eco" claims? Vague buzzwords can damage your brand’s credibility. I’ll show you how to focus on verifiable materials and true durability.

Choose verifiable options like vegan PBT bristles, recycled aluminum ferrules, and FSC-certified wood or biodegradable PLA handles. Publish your certifications. Avoid vague "eco" claims or calling synthetic fibers "organic," and remember that a durable, long-lasting brush is inherently more sustainable.

In today’s market, sustainability is a powerful part of a brand’s story. But your customers are smart—they can spot greenwashing5 from a mile away. I’ve always believed that true sustainability in manufacturing comes from two things: responsible material choices and building products that last. A brush that sheds and needs to be replaced in six months is not sustainable, no matter what its handle is made of. The goal is to make choices that are both environmentally conscious and deliver the high performance your customers expect. This builds trust and a brand that people are proud to support.

Real Sustainability vs. Greenwashing

| Do This (Verifiable Sustainability) | Don’t Do This (Greenwashing) |

|---|---|

| Use recycled PBT fibers or recycled aluminum and state the percentage. | Make vague claims like "eco-friendly" or "earth-conscious." |

| Choose FSC-certified wood or bamboo handles. | Claim synthetic bristles are "organic." |

| Opt for biodegradable PLA handles (and explain proper disposal). | Ignore durability; a disposable product is never sustainable. |

| Publish your chain-of-custody documents and certifications. | Use "green" marketing without any test results or proof. |

PLA (Polylactic Acid) is a biodegradable plastic made from renewable resources like corn starch.True

It's a popular choice for more sustainable brush handles, but it requires industrial composting facilities to biodegrade effectively, a detail often omitted in marketing.

Any brush with a bamboo handle is automatically sustainable.False

While bamboo is a fast-growing resource, sustainability also depends on the coatings, adhesives, and ferrules used. A durable, long-lasting brush often has a lower lifecycle impact than a poorly made 'eco' brush that's quickly discarded.

Conclusion

Sourcing non-toxic brushes means choosing safe materials, demanding documentation, and testing for quality. This protects your customers, builds your brand, and ensures your tools are beautiful and built to last.

References

-

Learn how nickel-plated brass ferrules enhance durability and prevent shedding in makeup brushes. ↩

-

Find out how FSC certification ensures sustainable sourcing of wood and bamboo in cosmetics. ↩

-

Investigate the factors leading to skin irritation and how to choose brushes that minimize this risk. ↩

-

Discover sustainable material options that enhance product longevity and reduce environmental impact. ↩

-

Understand the pitfalls of greenwashing and how to communicate genuine sustainability to consumers. ↩