Ever had a customer complain about a shedding brush? It’s frustrating and hurts your brand. The secret to a durable brush often lies in one small, overlooked part.

Yes, the ferrule is key. It’s the metal part connecting bristles to the handle. A well-made ferrule prevents shedding, ensures balance, and defines the brush’s long-term quality and luxury feel.

When I started on the factory floor, I quickly learned that the ferrule is more than just a shiny connector. It’s the structural core of the brush. For brand founders like you, understanding this component is a game-changer. It separates a good brush from a great one. Let’s break down exactly what you need to know to make the right choices for your brand.

The ferrule's only job is to hold the bristles.False

The ferrule also provides balance, protects the glue bond from moisture, and contributes significantly to the brush's overall durability and feel.

A well-crimped ferrule is crucial for preventing brush shedding.True

Proper crimping, along with a strong adhesive, physically locks the bristles in place, preventing them from falling out during use.

What Is a Makeup Brush Ferrule and How Does It Affect Shedding?

Shedding brushes can destroy a customer’s trust in your brand. It feels cheap. The solution starts with understanding the part responsible for holding everything together: the ferrule.

The ferrule is the metal sleeve that clamps the bristles to the handle. It works with adhesive to stop shedding. If the crimp is weak or the size is wrong, bristles will loosen and fall out.

From my years in manufacturing, I can tell you the ferrule has three main jobs. It’s not just a pretty piece of metal.

The Ferrule’s Core Functions

First, it provides the structural clamp for the bristles. We bundle the bristles, dip them in a strong adhesive, and then insert them into the ferrule. The ferrule is then crimped—squeezed with immense pressure—to lock the bristle base (the knot) in place. Second, it creates a secure connection to the handle. The handle has a small, carved-out section called a tenon that fits inside the ferrule. More adhesive is used here to create a solid, wobble-free bond. Finally, it adds balance and weight, which affects how the brush feels in the user’s hand.

How a Bad Ferrule Causes Shedding

Shedding almost always comes down to a failure in the ferrule system. If the ferrule crimp1 is too loose, the bristles can wiggle free. If the ferrule adhesive is low-quality or not applied correctly, it will break down. And if the inner diameter doesn’t perfectly match the bristle knot, there will be micro-gaps that lead to movement and eventual shedding. This is why fit trumps everything else.

All makeup brush shedding is caused by a loose ferrule.False

While a poor ferrule crimp is a primary cause, shedding can also result from low-quality adhesive, broken bristles, or improper brush care by the user.

The inner diameter of the ferrule must match the bristle knot and handle tenon.True

A precise fit prevents micro-gaps, which cause the brush head to wiggle and eventually break down the adhesive, leading to shedding and a loose handle.

Brass/Copper vs Aluminum Makeup Brush Ferrules: Which Should B2B Buyers Choose?

Choosing between brass and aluminum for your ferrules can be confusing. A wrong move can misalign the product’s feel with its price point. Here’s a clear guide to help you decide.

Choose brass or copper for premium, durable brushes where a heavier, luxurious feel is important. Choose aluminum for cost-effective, lightweight brushes, like for eye sets or high-volume kits, where a wide range of colors is a plus.

As a brand founder, your choice between brass (or its cousin, copper) and aluminum comes down to your target market, desired user experience, and budget. There is no single "best" material; there’s only the best material for your specific brush line. I’ve seen brands succeed with both. To make it simple, I’ve created this decision table based on what I see working for hundreds of clients.

Ferrule Material Comparison for B2B Buyers

| Material | Typical Finish Options | Relative Durability | Weight/Balance | Cost Tier | Best For |

|---|---|---|---|---|---|

| Brass/Copper | Nickel, Chrome, Gold, Black Plating | High (resists dents) | Heavier, premium feel | Higher | Premium face brushes, professional lines, luxury sets. |

| Aluminum | Anodized or Painted Colors | Moderate (can dent) | Lightweight, easy to handle | Cost-Efficient | Eye brush sets, travel kits, high-volume promotional items. |

For my clients launching a premium, single powder brush, we almost always go with a thick-walled brass ferrule. The weight instantly signals quality. But for a 12-piece eye brush set sold online, lightweight, colorful aluminum ferrules are the smarter choice to manage costs and create visual appeal.

Brass ferrules are always better than aluminum ferrules.False

Brass is more durable and heavier, making it ideal for luxury brushes. However, aluminum is more cost-effective, lighter, and offers more color options, making it better for high-volume or travel-sized kits.

Anodized finishes are only available for aluminum ferrules.True

Anodizing is an electrochemical process that forms a durable, decorative oxide layer on the surface of aluminum. Brass and copper are typically finished with electroplating.

How Makeup Brush Ferrule Specs (Thickness, ID, Plating) Impact Cost and Lead Time?

Surprised by a high quote or a long lead time for your custom brushes? These unexpected changes can derail your budget and launch schedule. Let’s uncover the hidden cost drivers.

Thicker materials, tighter tolerances, and complex finishes like gold plating increase costs and production time. Custom decorative lines or non-standard shapes require new molds, which adds significant cost, MOQ, and lead time for mold fabrication and trials.

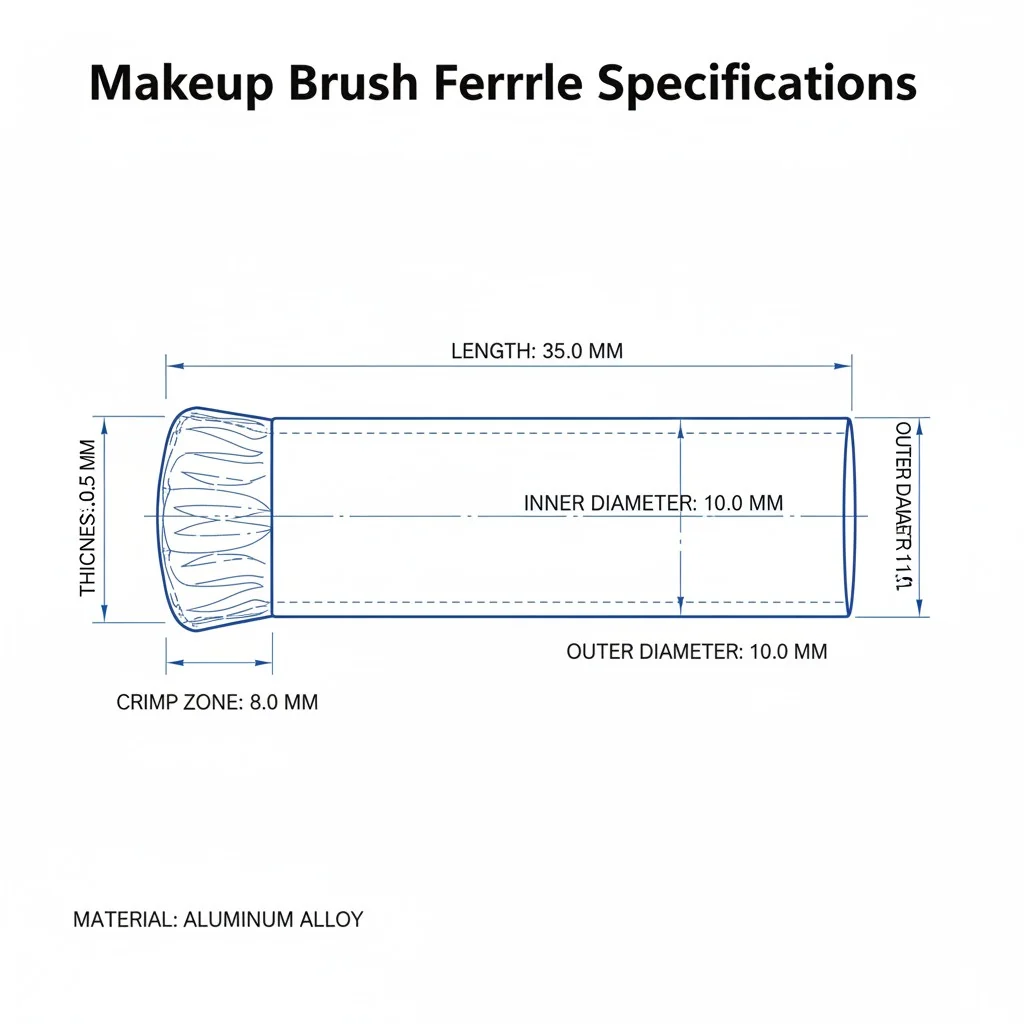

The final price and delivery date of your brushes are not just about the material. Tiny details in the ferrule’s design can have a huge impact. When you’re sourcing, you need to be aware of these levers. I always tell my clients to get a detailed spec sheet approved before paying a deposit. Here are the key specs to watch.

How Ferrule Specs Affect Your Order

| Spec | Why It Matters | Impact on Cost/MOQ/Lead Time |

|---|---|---|

| Thickness (Gauge) | Durability and perceived weight. | Higher cost for thicker material. |

| inner diameter2 (ID) Tolerance | Ensures a tight fit with bristles/handle. | Tighter tolerances require more QC, slightly raising cost. |

| Plating/Finish Type | Aesthetics and corrosion resistance. | Standard chrome is baseline; gold/black plating is more expensive. |

| Decorative Lines/Rings | Adds unique branding detail. | Adds a manufacturing step, increasing cost and lead time slightly. |

| Custom Molds | For unique shapes not in the supplier’s library. | High initial cost, higher MOQ, and adds 4-6 weeks to lead time. |

The biggest jump in cost and time comes from needing a custom mold. If your design can use an existing mold, you’ll save thousands of dollars and weeks of time. Always ask your supplier for their catalog of existing ferrule shapes and sizes first.

Adding decorative rings to a ferrule does not affect the cost.False

Adding decorative rings or lines requires an additional manufacturing step, which increases labor and machine time, thus adding to the unit cost.

Using a supplier's existing ferrule mold is faster and cheaper than creating a custom one.True

Creating a custom mold involves design, fabrication, and trial runs, which can cost thousands of dollars and add over a month to the lead time. Using an existing mold avoids these costs and delays.

Makeup Brush Ferrule Manufacturing Steps and QC Tests You Should Require?

Your sample was perfect, but the bulk order is full of duds. This inconsistency is a brand killer. You can prevent this by knowing what to look for during production.

Manufacturing involves cutting, polishing, tapering, plating, and crimping. You should require QC tests for finish quality (no scratches), crimp integrity, and pull strength to ensure the ferrule won’t loosen or bristles won’t shed.

A ferrule looks simple, but it goes through many steps before it’s ready. As a buyer, you don’t need to be an expert in every step, but you should know the key stages and where things can go wrong. This allows you to ask your supplier the right questions. Here is the typical process and the QC checks I insist on for my clients.

Ferrule Manufacturing & QC Checklist

| Step | Purpose | Typical Defects to Watch | QC Notes |

|---|---|---|---|

| Cutting & Tapering | Shape the metal tube. | Incorrect length, inconsistent taper. | Verify dimensions against the approved drawing. |

| Polishing | Create a smooth surface for plating. | Scratches, uneven surface. | Visual inspection under good lighting. |

| Plating/Coating | Apply the final color and finish. | Color variation, peeling, bubbles. | Check against Pantone/RAL code; perform abrasion/sweat tests. |

| Crimping | Secure the ferrule to the handle/bristles. | Loose fit, wobbly head, damaged handle. | Perform pull and torque tests to check strength. |

The most critical QC tests are the pull test and torque test. We use a machine to pull and twist the brush head to ensure the crimp and adhesive can withstand a specific force (e.g., 5kg). This simulates real-world use and guarantees the brush won’t fall apart. Don’t be afraid to ask your supplier for their QC test reports.

A visual inspection is enough to guarantee a ferrule's quality.False

Visual inspection only checks for surface defects. Mechanical tests like pull strength and torque tests are required to verify the structural integrity of the crimp and adhesive bond.

De-oiling is a necessary step before plating a ferrule.True

Oils and residues from the polishing and shaping stages must be completely removed. If not, the plating will not adhere properly and can lead to bubbling, peeling, or flaking.

Conclusion

The ferrule is the heart of a quality makeup brush. Pay attention to its material, specs, and QC, and you will build a product that lasts and delights your customers.