Launching a brush line feels overwhelming. You worry about quality, high minimums, and confusing compliance1. We provide a clear, fast path to launch your brand with confidence.

Private label makeup brushes2 are custom-branded tools made by an OEM factory. To launch fast, you specify the fiber, shapes, logo, and packaging. Expect samples in 7–14 days and production in 30–45 days, with MOQs of 100–500 sets or 300–1,000 singles.

I know the feeling of having a great brand vision but hitting a wall with suppliers. When I first started, I saw so many passionate founders get discouraged by factories that wouldn’t give them the time of day. They were stuck with slow responses, inaccurate samples, and a total lack of transparency. It’s why I built Brushino to be different. We’re not just a factory; we are your partner. We give you a practical, step-by-step guide to creating brushes that your customers will love, and we do it with the speed and quality your brand deserves. Let’s walk through exactly how it works.

The global makeup brush market is projected to reach $12.9 billion by 2034.True

According to a 2025 report by Global Market Insights, the market is growing at a 6.3% CAGR, driven by social media trends and the demand for pro-grade tools.

All makeup brush factories require a minimum order of 5,000 pieces.False

Many modern factories, including Brushino, offer low MOQs starting from 100-500 sets to support independent and emerging beauty brands.

How do private label makeup brushes work with customization, MOQs, sampling, and timelines?

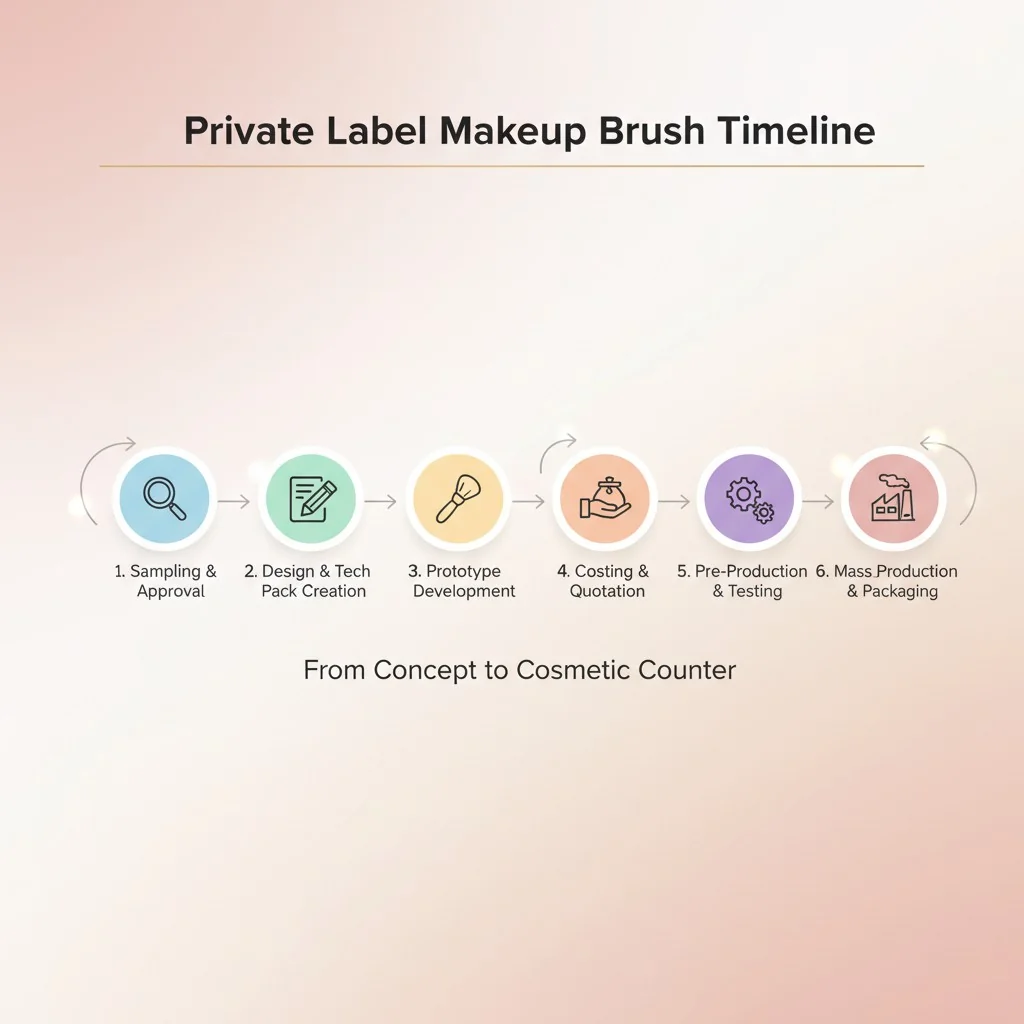

Struggling to get a clear process from a factory? You need a simple roadmap for customization3, costs, and timelines. We make it transparent so you can plan your launch effectively.

Private label OEM means you choose the fiber, ferrule, handle, logo, and packaging. We then engineer it to meet your performance goals. Expect MOQs4 from 100–500 for sets, samples in 7–14 days, and production in 30–45 days.

When you decide to create your own brush line, you’re in the driver’s seat. The goal is to move from idea to a market-ready product without friction. I’ve seen too many projects get delayed because the initial brief was incomplete. To get an accurate quote and fast samples, you need to be specific. This is what a strong brief, or Request for Quotation (RFQ), looks like.

Key Customization Modules

- Hair/Fibers: Choose from vegan synthetics or natural hair based on performance and brand values.

- Ferrule: The metal part. Aluminum is standard and cost-effective; copper offers a more premium weight and feel. Finishes can be matte, glossy, or metallic.

- Handle: Wood is the most common, but we also offer sustainable options like bamboo (FSC-certified) or recycled materials. Shape, length, and color are fully customizable.

- Logo: We can do silk-screen printing, pad printing, hot stamping, or laser engraving.

- packaging5: From simple poly bags to custom-printed boxes or travel pouches, the packaging is a key part of your brand story.

Typical MOQs and Timelines

| Category | Typical MOQ | Sample Lead Time | Production Lead Time |

|---|---|---|---|

| Single Face Brush | 300–1,000 pcs | 7–14 days | 30–45 days |

| Single Eye Brush | 500–2,000 pcs | 7–14 days | 30–45 days |

| 7–15pc Brush Set | 100–500 sets | 10–20 days | 35–60 days |

| Opakowanie niestandardowe | 500–2,000 units | 10–20 days | 25–40 days |

Sampling always takes over a month for custom brushes.False

If standard materials are in stock, a good factory can produce custom samples in 7-14 days. Delays usually happen when new tooling or non-stock materials are required.

Offline retail still accounts for about 65% of makeup tool sales.True

A Global Market Insights report noted that consumers still prefer to physically evaluate the feel and quality of brushes in-store, making tactile quality crucial for private label brands.

Are vegan fibers as good as natural hair for performance, compliance, and cost?

You want cruelty-free brushes but worry they won’t perform like natural hair. This creates a conflict between your brand ethics and product quality. We’ll show you how modern synthetics outperform natural hair.

Today’s advanced synthetic fibers, like dual-denier and micro-crimped PBT, match or exceed natural hair for most uses. They offer pro-level pickup and blending, support cruelty-free claims, and provide more consistent quality control, making them the preferred choice for EU and US markets.

The debate between vegan and natural fibers is one I have with clients all the time. Years ago, natural hair was the undisputed king for performance, especially with powder products. But technology has changed everything. The shift toward synthetic fibers isn’t just about ethics; it’s driven by huge gains in performance. From my experience on the factory floor, I can tell you that the engineering behind a synthetic fiber bundle is incredibly precise.

Fiber Performance Deep Dive

- For Foundation: We use dual-denier PBT blends. These have fibers of two different thicknesses with heat-set tips. This combination lays down liquid and cream foundation much more smoothly than a standard synthetic brush.

- For Eyeshadow: For packing on shimmer or glitter, micro-crimped PBT fibers are a game-changer. The tiny crimps create more surface area, which dramatically improves pigment pickup compared to smooth fibers.

This level of specialization means we can create a vegan brush that is specifically engineered for a certain task, often outperforming a generic goat hair brush.

Fiber Options and Use-Cases

| Fiber Type | Use-Case | Performance | Cost Tier | Compliance |

|---|---|---|---|---|

| PBT Synthetic (single‑denier) | General face/eye | Good | $ | Vegan/cruelty‑free |

| PBT Synthetic (dual‑denier, heat‑set) | Foundation/contour | Excellent smoothing | $$ | Vegan/cruelty‑free |

| Micro‑crimped PBT | Eye detail, shimmer | High pickup/precision | $$ | Vegan/cruelty‑free |

| Natural goat/sable blends | Powder diffusion | Soft feel | $$$ | Not vegan; animal welfare concerns |

Synthetic brushes are always cheaper than natural hair brushes.False

While basic synthetics are cost-effective, high-performance engineered synthetics (like dual-denier or micro-crimped PBT) can be priced similarly to or higher than mid-grade natural hair due to the advanced technology involved.

The beauty industry is shifting toward vegan and cruelty-free products.True

Market trend reports, like one from GMI in 2025, confirm that consumer preference and performance gains are driving the adoption of synthetic fibers over natural animal hair.

What packaging and certifications must buyers prepare for the EU and US?

You’re ready to sell in the EU or US but are terrified of your shipment being rejected by customs. The rules seem complex and impossible to navigate. We help you prepare all necessary documentation from the start.

For EU/US retail, you need factory audits (ISO, BSCI), material safety reports (REACH for EU, Prop 65 docs for US), and clear sustainability claims (FSC for wood, recycling logos). We build these compliance checks into the sampling6 phase to prevent delays.

Compliance is not something you can afford to think about at the last minute. I’ve seen brands have their entire inventory held up at port because of a missing report on the ink used for their logo. It’s a costly and stressful mistake. That’s why we treat documentation as part of the product itself. For my clients, especially those like Emily who are targeting discerning markets in the US and EU, we prepare a full compliance package.

Essential Audits and Reports

- Factory Audits: We maintain ISO 9001 (for quality management) and BSCI/SMETA (for social compliance). These show retailers you partner with a responsible and reliable manufacturer.

- EU Compliance (REACH): Sourcing experts will tell you to screen for Substances of Very High Concern (SVHCs) during sampling. This applies to everything—the handle coating, the glue in the ferrule, and the ink on the packaging. We get lab reports early to avoid surprises.

- US Compliance (Prop 65): For California and increasingly for national retailers like Amazon, you need to prove your products are free of certain chemicals. We keep a traceability folder with lab reports for heavy metals in ferrules and pigments.

- Sustainability Claims: If you want to use an FSC logo on your wooden handles or a recycling symbol on your box, you need a documented chain of custody. We provide this so your green claims are 100% verifiable.

A BSCI audit proves a product is high-quality.False

BSCI (Business Social Compliance Initiative) is an audit focused on social and ethical standards, like working conditions and fair wages. ISO 9001 is the certification that relates to a factory's quality management system.

Documenting materials for REACH and Prop 65 during sampling saves time and money.True

Sourcing and compliance experts advise getting lab reports for coatings, adhesives, and inks early. Finding a compliance issue after mass production has started can lead to costly rework and major shipping delays.

How is pricing logic explained, and what drives brush costs?

You get quotes from factories that vary wildly, with no explanation. This makes it impossible to budget or understand what you’re paying for. We break down the costs so you can make smart choices.

Brush costs are driven by fiber type/density, ferrule metal (aluminum vs. copper), handle material/finish, and logo method. You can optimize costs with standard shapes, synthetic fibers, aluminum ferrules, and by ordering sets to consolidate packaging and QC.

Pricing shouldn’t be a mystery. When I work with brand founders, I walk them through exactly where their money is going. A brush that costs $1 to make can easily become $3 with a few small changes. Understanding these drivers helps you design a product that meets both your quality standards and your budget. It’s all about making intentional trade-offs.

Primary Cost Drivers

- Fibers: This is often the biggest cost factor. High-performance, dense, dual-denier synthetic fibers cost more than basic single-denier fibers. Natural hair is typically the most expensive.

- Ferrule: Lightweight aluminum is the standard. Heavier copper or brass feels more luxurious but costs significantly more.

- Handle: A standard painted wood handle is cost-effective. Complex shapes that require new molds, multi-layer lacquer finishes (like a 2K PU coating for scratch resistance), or sustainable materials7 like FSC-certified wood will increase the price.

- Logo: A simple one-color pad or silk-screen print is cheapest. Multi-color logos, hot-foil stamping, or laser engraving add cost.

- Order Quantity: As with any manufacturing, larger orders reduce the per-unit cost. Our low MOQs are designed for accessibility, but there are price breaks at higher volumes.

By understanding this, you can "design to cost." For example, you might invest in a high-performance fiber for your foundation brush but choose a more standard fiber and aluminum ferrule for a powder brush in the same set to balance the overall cost.

The handle is the most expensive part of a makeup brush.False

Generally, the fiber bundle (hair) is the most significant cost driver, especially for dense brushes or those using high-performance synthetic or premium natural hair.

Using a water-borne PU coating on a handle improves scratch resistance.True

Factory data shows that water-borne polyurethane (PU) coatings with a 2K hardness rating are significantly more durable in retail environments than standard nitrocellulose lacquer, preventing scratches and improving perceived quality.

Conclusion

Building your dream brush line is achievable with the right partner. We provide the transparency, quality, and speed you need to launch and scale your brand successfully.

References

-

Learn about the essential compliance documentation needed for selling in international markets. ↩

-

Explore how private label makeup brushes can enhance brand identity and customer loyalty. ↩

-

Learn about the various customization options available for creating unique makeup brushes. ↩

-

Understand the minimum order quantities required for launching your own makeup brush line. ↩

-

Explore how packaging can enhance your brand story and attract customers. ↩

-

Discover the importance of sampling in ensuring product quality before mass production. ↩

-

Explore eco-friendly options for creating sustainable and ethical makeup brushes. ↩