You want to launch a custom brush line, but finding a reliable factory feels impossible. You worry about poor quality, hidden costs, and missed deadlines that could ruin your launch.

Private label makeup brushes1 help B2B brands launch custom, certified brush lines fast. Choose an OEM/ODM factory with ISO/BSCI/SMETA/FSC, commit to AQL 2.5+ testing, and secure sampling SLAs (quotes in 1–3 days, prototypes in 7–10). Control cost via fiber grade, ferrule metal, handle finish, logo method, and packaging. Expect 25–45 days for production after approvals, then 7–20 days for shipping.

When I first started my journey on the floor of a brush factory, I saw the disconnect every day. Brand founders like you have an amazing vision for your products. But the path to bringing that vision to life is often filled with confusing quotes, broken promises, and a total lack of transparency. It’s frustrating, and it puts your business at risk. I built my own company to fix this. I wanted to create a process that was clear, fast, and supportive for brand owners. This guide is the roadmap I wish I had when I started, and it’s designed to help you stop searching and start building with confidence.

Synthetic bristles made up about 60% of the makeup tools market in 2023.True

This is supported by industry reports, driven by the demand for cruelty-free products and advancements in synthetic fiber performance.

All makeup brush factories provide a clear compensation policy for defective products.False

Many factories lack clear, written policies, leaving brands at risk if quality issues arise. It's crucial to demand this in your purchase order.

How Do You Choose a Private Label Makeup Brush Factory You Can Trust?

Vetting factories feels like a black box. You send emails into the void, hoping for a good partner but fearing you’ll get stuck with poor quality, bad communication, and delays.

To find a reliable partner, focus on three things: their quality control (QC) standards2, their certifications, and their service level agreements (SLAs) for sampling. A great factory will be transparent about all three before you even place an order.

Choosing the right factory is the single most important decision you’ll make. A great partner acts as an extension of your team, while a bad one creates constant problems. I’ve seen brands get burned by factories that overpromise and underdeliver. To avoid this, you need to look for concrete proof of their capabilities. Don’t just take their word for it; ask for documentation and clear commitments. A professional factory will welcome your questions and provide the evidence you need to feel secure.

Demand a Clear QC Dossier

AQL (Acceptable Quality Limit) is the industry standard, and you should look for AQL 2.5. But that’s just the start. For premium products, especially those with white bristles or light-colored handles, this isn’t enough. I learned that adding specific tests dramatically reduces returns. Ask your potential partner if they also perform a ferrule pull test (it should withstand at least 20 kgf), color-transfer tests, and a 100% re-check after any rework.

| Test Type | Standard | Why It Matters |

|---|---|---|

| AQL Standard | Level II, 2.5/4.0 | Sets the baseline for acceptable defects in a batch. |

| Ferrule Pull Test | ≥20 kgf | Ensures the brush head won’t detach from the handle during use. |

| Shedding Test | Minimal to no loss | Guarantees bristles won’t fall out on the customer’s face. |

| Logo Adhesion Test | 3M tape test | Confirms your branding won’t scratch or peel off easily. |

Verify Key Certifications

Certifications are not just logos on a website; they are proof of a factory’s commitment to quality, ethics, and sustainability. For brands selling in the US and EU, these are increasingly non-negotiable.

- ISO 9001: This means the factory has a documented quality management system. It shows they are serious about process and consistency.

- BSCI/SMETA: These are social compliance audits. They ensure workers are treated fairly and ethically, which is a core value for many brands and their customers.

- FSC: The Forest Stewardship Council certification guarantees that any wood used for handles comes from responsibly managed forests.

- ECOVADIS: This is a broad corporate social responsibility (CSR) rating that top retail partners look for.

Lock in Sampling Service Level Agreements (SLAs)

"We’ll get back to you soon" is not an acceptable timeline. Speed and accuracy during sampling are indicators of how the factory will perform during mass production. A professional factory should be able to commit to a clear SLA. We promise quotes in 24-72 hours and functional prototypes in 7-10 days because we know that speed is critical for your launch. If a factory can’t give you a firm timeline for a sample, how can you trust their production lead time?

ISO 9001 certification guarantees that every single brush produced will be 100% free of defects.False

ISO 9001 certifies that a factory has a quality management *system* in place. It ensures processes are followed to minimize defects, but it does not guarantee zero defects.

BSCI and SMETA audits help verify a factory's social and ethical labor practices.True

These audits are crucial for brands that prioritize ethical sourcing and want to ensure their partners meet international labor standards.

What Really Drives the Cost of Your Custom Makeup Brushes?

You get a quote, but the price feels arbitrary. You want to make changes to fit your budget, but you don’t know which features are driving up the cost, leaving you to guess.

The final unit price is a sum of its parts. The biggest drivers are the fiber, ferrule, handle, logo, and packaging. For small brands with low MOQs, the finishing processes and packaging complexity have a disproportionately large impact on cost.

When I work with brand founders, one of the first things we do is build a "price ladder." Instead of giving one price for one design, we quote three configurations: Value, Core, and Premium. This makes it easy for you to see exactly how your choices impact the final cost. For example, you might see that switching from a brass ferrule to an aluminum one saves you $0.15 per unit, or that a multi-layer lacquer finish adds $0.25. This transparency empowers you to make strategic, budget-conscious decisions without starting the sourcing process all over again.

The Big Three: Fibers, Ferrules, and Handles

These components form the core of the brush and its cost.

| Component | Value Option | Core Option | Premium Option |

|---|---|---|---|

| Fiber | Standard Synthetic | Engineered Synthetic | Custom Mixed Fibers |

| Ferrule | Aluminum | Anodized Aluminum | Brass |

| Handle | Plastic (ABS) | FSC-Certified Wood | Lacquered Wood / Resin |

For most brands, I recommend starting with high-performance engineered synthetic fibers. They offer amazing consistency, are cruelty-free, and sample much faster than natural hair.

The Finish and The Brand: Logos and Packaging

Finishes and packaging can be silent margin killers, especially at low quantities. A simple silk-screened logo is very cost-effective, while a hot foil stamp adds a premium touch but also more cost. The same goes for packaging. A simple polybag is cheap, but a custom-printed paper tube with a matte finish and foil logo can add 12-18% to your total unit cost on a small run. It’s beautiful, but you need to be aware of the trade-off early in the design process to avoid surprises.

Brass ferrules are always cheaper than aluminum ferrules.False

Aluminum is generally the more cost-effective metal for ferrules. Brass is heavier and considered more premium, so it typically costs more.

At low MOQs, complex packaging can add more than 15% to the total unit cost of a brush.True

Setup fees and material costs for custom packaging are spread over fewer units, making it a significant cost driver for small orders.

From Prototype to Your Door, What Are Realistic Project Lead Times?

You’re told your order will be ready in 30 days, but 60 days later, you’re still waiting. These unexpected delays destroy your launch schedule and waste your marketing budget.

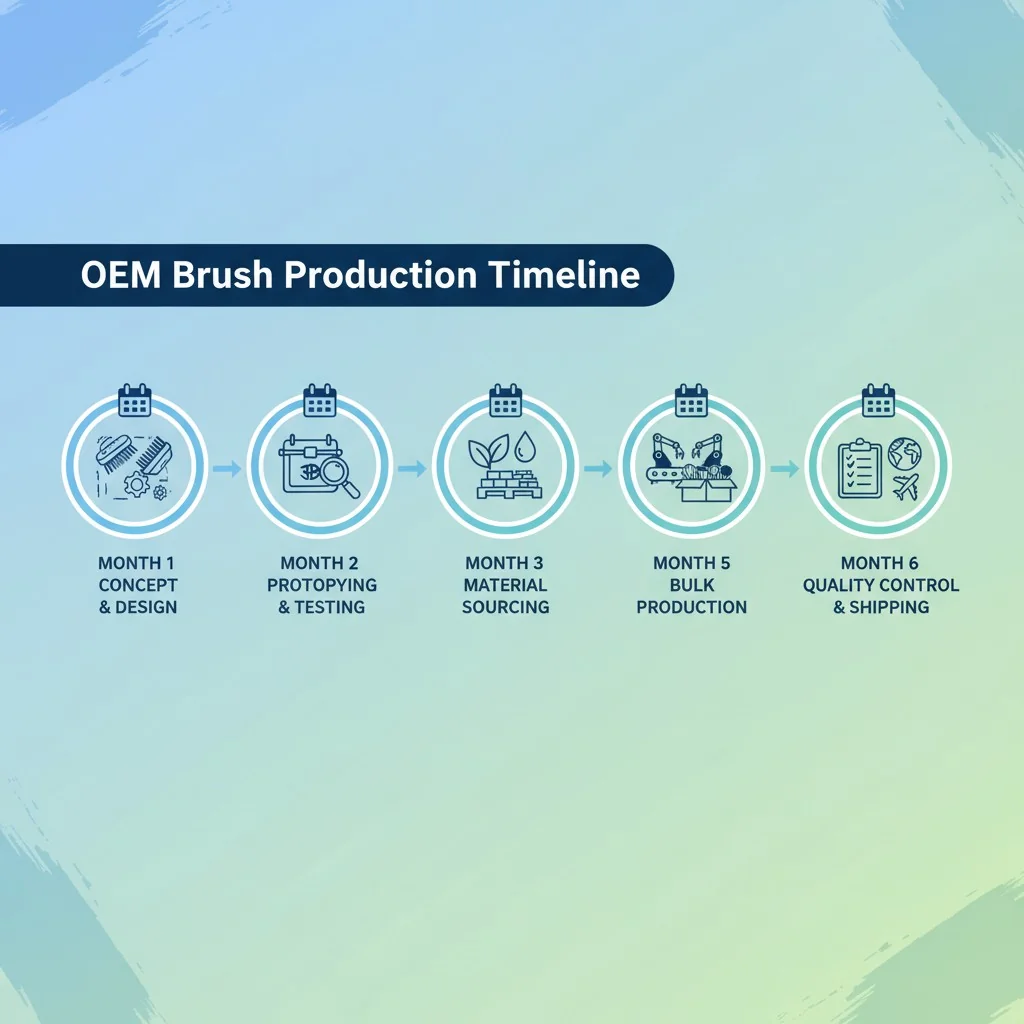

A realistic end-to-end timeline is 40 to 80 days. This breaks down into 1-2 weeks for pre-production (quotes, samples, approvals), 4-6 weeks for mass production, and 1-3 weeks for logistics. Always add a buffer for holidays and complex finishes.

One of the biggest mistakes I see brands make is not accounting for the "hidden" steps in the timeline. They only think about the mass production time. But the pre-production approval process can take longer than expected if there are multiple revisions. You also have to factor in material procurement, which can take a week or more before production even starts. And don’t forget about logistics! Booking freight, customs clearance, and final delivery all take time. A transparent partner will map out every single one of these milestones for you, including buffers for things like the Chinese New Year holiday, which can shut down factories for weeks.

Phase 1: Pre-Production (1–2 Weeks)

This is where speed and communication matter most. It includes your initial inquiry, quotation (1-3 days), and prototype development (7-10 days). To shorten this phase, I strongly recommend a two-sample protocol. First, approve a "function sample" that locks in the brush head and fiber performance. Once that’s perfect, we move to an "aesthetic sample" to finalize the handle color, finish, and logo. This prevents you from having to restart the whole process if you want to change a color.

Phase 2: Mass Production (4–6 Weeks)

This begins the moment you approve the final pre-production sample and submit your PO. The clock starts with material procurement (fibers, ferrules, handles). Then comes assembly, finishing, logo application, and final quality control inspections. If your brush has a complex, multi-layer lacquered handle, add an extra 5-7 days to this phase.

Phase 3: Logistics (1–3+ Weeks)

Once production is complete and QC is passed, your brushes are ready to ship. Air freight is the fastest (about 7-10 days) but most expensive. Sea freight is more economical but takes much longer (20-40 days depending on the destination). For urgent launches, I often advise clients to use a split shipment: air freight a small portion for your launch day and ship the rest by sea to save money.

Chinese New Year does not affect production timelines for makeup brush factories in China.False

Chinese New Year is a major holiday that can shut down factories for 2-4 weeks. Brands must plan around it to avoid significant delays.

A two-sample protocol (functional then aesthetic) can shorten the overall project timeline.True

By separating performance approval from finish approval, it reduces the number of full-scope revisions and shortens the pre-production phase.

How Can Indie Brands Launch Brushes with a Low MOQ?

You’re an indie brand with a great idea, but every factory tells you their Minimum Order Quantity (MOQ) is 5,000 pieces per style. This forces you to over-invest and risk being stuck with inventory.

You can launch with as few as 100-500 units per style. The key is to find a factory that allows SKU mixing3, helps you choose small-run-friendly packaging, and offers transparent risk-control measures from the start.

As someone who helps indie brands every day, I know that high MOQs are the biggest barrier to entry. That’s why we built our model to support founders like you. The secret isn’t just about finding a factory with a low number; it’s about finding one that thinks strategically with you. For example, while our total order minimum might be 3,000 units, we can split that across 6 different brush styles at 500 units each. This allows you to launch a full, cohesive set instead of just one or two brushes. It’s about finding a partner who is willing to be flexible to help you grow.

The Power of SKU Mixing and Smart Components

Don’t be afraid to ask a potential partner if you can mix and match SKUs to meet their total order value or quantity. A flexible factory will work with you. You can also keep costs down by using standardized components (like a common handle shape or ferrule size) across different brush heads. This allows the factory to produce more efficiently, and they can pass those savings on to you, even at lower volumes.

Small-Run Packaging and Risk Control

As I mentioned before, complex packaging is expensive in small quantities. For your first run, consider simpler, more affordable options. A nicely designed sleeve over a stock box or a branded pouch can look incredibly premium without the high cost of a fully custom-molded solution. Most importantly, protect your investment. Before you sign a PO, make sure you have a clear QC plan, have approved a final sample, and have a written compensation policy for any potential quality issues. This de-risks your first order and lets you move forward with peace of mind.

The only way to get a low MOQ is to accept lower quality materials.False

Strategic factories offer low MOQs by allowing SKU mixing, using smart component choices, and optimizing their production for smaller batches, without compromising on quality.

Mixing SKUs allows a brand to launch a wider variety of brushes while still meeting a factory's total minimum order requirement.True

This is a key strategy for indie brands to create a complete brush set or collection without over-investing in any single style.

What Does the Data Say About the Makeup Brush Market?

Understanding the market helps you make smarter decisions. The demand for makeup brushes is strong and growing, with a clear trend towards synthetic, cruelty-free options.

| Market Metric | Data Point | Source / Year |

|---|---|---|

| Global Market Size | USD 3.72 Billion | (2024 Projection) |

| Projected Growth | USD 6.01 Billion by 2034 | (CAGR ~4.9%) |

| Synthetic Bristle Share | ~60% of tools market | (2023) |

| Fastest-Growing Region | Asia-Pacific (APAC) | (2023) |

Data synthesized from multiple market research reports; figures are estimates and vary by methodology.

Your Top Questions About Private Label Brushes, Answered

What is a realistic MOQ for private label brush sets?

For indie brands, 100–500 units per style is a realistic starting point with the right factory in China. This is often achieved by mixing SKUs to meet a larger total order value. Global leaders may require 5,000+ units per style.

How long from quote to delivery?

A typical timeline is 40-80 days. This includes 1–3 days for quotes, 7–10 days for a prototype, 25–45 days for mass production, and 7–20 days for shipping. Complex finishes and holidays can extend this.

Which certifications matter for B2B buyers?

Focus on ISO 9001 (quality systems), BSCI/SMETA (social compliance), and FSC (sustainable wood). These are increasingly required by major retailers in the EU and US and show a factory’s professionalism.

Synthetic vs. natural hair: which should I choose?

Synthetic hair is the market leader. It offers excellent performance, consistency, hygiene, and is vegan/cruelty-free. Natural hair can be great for powder pickup in pro-level lines but adds cost and sourcing complexity.

What drives unit price the most?

The biggest factors are fiber grade, ferrule metal (brass costs more than aluminum), handle material and finish, logo method, and packaging. For low MOQs, complex finishes and packaging have the largest impact on price.

How do I minimize risk on my first run?

First, lock in the brush performance with a functional sample. Second, choose standard finishes to avoid complexity. Third, get a full QC dossier and a written compensation policy in your purchase order.

Ready to Start? Use These Checklists.

To make it even easier, think of your project in these stages. Make sure you have clear answers for each before moving to the next.

- Factory Vetting Checklist (Certifications, SLAs, Communication)

- Sampling & Prototype Checklist (Function, Aesthetics, Revisions)

- QC & Production Checklist (AQL, Testing, Timelines)

- Packaging & Logistics Checklist (Cost, Small-Run Options, Shipping)

Conclusion

Finding the right OEM partner is the key to your success. With a focus on transparency in quality, cost, and timelines, you can confidently launch the beautiful, high-performance custom brush line your brand deserves.