Choosing the right makeup sponge feels overwhelming. The wrong one wastes product or leaves a streaky finish. Understanding the core materials helps you source the perfect tool for a flawless application.

Makeup sponges are mainly made from hydrophilic polyurethane foam1, which is latex-free. Other common materials include latex, non-porous silicone, and soft microfiber. For eco-conscious brands, natural cellulose or sea sponges are biodegradable options, though best for cleansing. For sensitive users, always choose latex-free polyurethane.

As a brand founder or sourcing manager, the material you choose for your makeup sponge is more than just a technical detail. It defines the user experience, impacts product performance, and communicates your brand’s commitment to quality and safety. I’ve spent years on the factory floor and working with brands like yours, and I’ve seen firsthand how the right material choice can elevate a product line. Let’s break down the options so you can make an informed decision that aligns with your brand’s vision and your customers’ needs.

All makeup sponges are made from the same type of foam.False

Makeup sponges are made from various materials, including polyurethane, latex, silicone, and microfiber, each offering different performance benefits.

Using a damp makeup sponge helps reduce product absorption.True

Wetting a hydrophilic polyurethane sponge causes it to swell, filling its open cells with water and leaving less room for makeup to soak in.

Why Is Hydrophilic Polyurethane the Industry-Standard, Latex-Free Makeup Sponge?

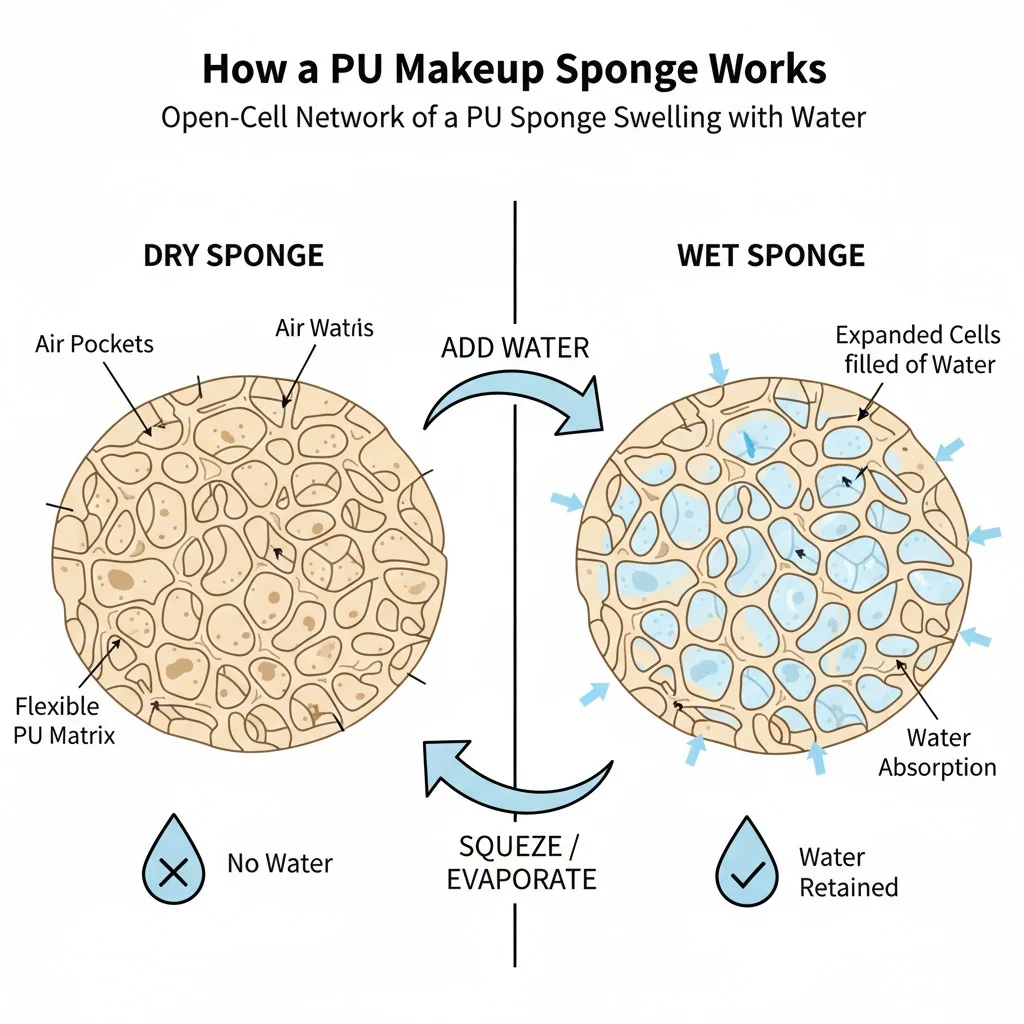

You want to offer a tool that gives a perfect, airbrushed finish. But many sponges absorb too much expensive foundation. Hydrophilic polyurethane solves this by swelling when wet for a seamless blend.

Hydrophilic polyurethane (PU) is the top choice because its open-cell structure expands with water. This creates a smooth, bouncy surface for streak-free blending of liquids and creams. It also minimizes product absorption and is naturally latex-free, making it a safe choice for all users.

When I work with brand owners, PU foam is almost always my top recommendation for a classic blending sponge. Its popularity isn’t just a trend; it’s based on proven performance that customers love. The "hydrophilic" or "water-loving" nature is the key.

The Science of the Swell

The magic of a PU sponge is its open-cell network. Think of it as a microscopic honeycomb. When you dampen the sponge, water fills these tiny pockets. This causes the sponge to swell and become incredibly soft. More importantly, with the cells already full of water, there’s less room for your liquid foundation or concealer to soak in. The makeup sits on the surface, ready to be blended onto the skin. This process is what allows for that beautiful, skin-like finish and reduces product waste.

Polyether vs. Polyester PU

Not all PU foams are created equal. They generally fall into two categories: polyether-based and polyester-based. From my experience in manufacturing, polyether-based PU2 is typically the superior choice for beauty tools. It offers better elasticity and "bounce-back," which customers associate with a high-quality sponge. It also has greater resistance to humidity and tearing, meaning it can withstand daily squeezing and washing for longer. This durability is a key factor for customer satisfaction and reflects well on your brand’s quality.

| Feature | Polyether-Based PU | Polyester-Based PU |

|---|---|---|

| Elasticity | Higher ("Bouncier") | Lower |

| Tear Strength | More Durable | Less Durable |

| Humidity Resistance | Better | Weaker |

| Best For | Premium, long-lasting sponges | Lower-cost, disposable sponges |

Polyether-based PU sponges are more durable than polyester-based ones.True

Polyether PU generally has better tear strength and humidity resistance, helping it last longer through repeated use and washing.

What Do You Need to Know About Latex Sponges (NR/SBR/NBR)?

You see inexpensive latex sponges everywhere, often in wedge shapes. But they can cause serious allergic reactions and don’t always work well with modern formulas. Knowing the different types helps you avoid risks.

Latex sponges include natural rubber (NR), styrene-butadiene rubber (SBR), and nitrile-butadiene rubber (NBR). While some are good for powders (SBR) or oils (NBR), natural rubber contains proteins that can trigger allergies in a significant portion of the population, posing a risk to your customers.

For brand owners, especially those targeting sensitive skin or selling in markets with strict regulations, the allergy risk associated with latex is a major concern. It’s a conversation I have frequently with clients. While latex can be effective for certain applications, the potential for a negative customer reaction often outweighs the benefits.

Decoding the Acronyms

It’s helpful to know what the letters mean when you’re talking to a supplier.

- NR (Natural Rubber): This is the traditional latex. It’s very porous but can break down quickly when exposed to oils in makeup. This is the primary source of latex allergies3.

- SBR (Styrene-Butadiene Rubber): A synthetic rubber that is softer and works well for picking up powder products. It’s less absorbent than NR.

- NBR (Nitrile-Butadiene Rubber): Another synthetic rubber known for its excellent resistance to oils and chemicals. This makes it a durable choice for applying oil-based liquid foundations.

The Allergy Risk Explained

The most critical factor here is the allergy risk from natural rubber (NR). The proteins in NR can cause sensitization. According to data from the CDC and NIOSH, this affects about 1% of the general population. The rate is much higher among healthcare workers, at 8-12%, due to frequent exposure. For a beauty brand, even a 1% risk is significant. It can lead to customer complaints, returns, and damage to your brand’s reputation. This is why most premium brands have moved to latex-free PU.

| Latex Type | Primary Use | Oil Resistance | Allergy Risk |

|---|---|---|---|

| NR | General use, powders | Poor | High |

| SBR | Powder application | Fair | Low (Synthetic) |

| NBR | Liquid/Oil-based foundation | Excellent | Low (Synthetic) |

Latex allergies are extremely rare, affecting less than 0.1% of people.False

Latex sensitization affects approximately 1% of the general population and can be as high as 8-12% in frequently exposed groups like healthcare workers, according to CDC and NIOSH data.

Silicone vs. Microfiber: Which Sponge Wastes Less Product?

You’re tired of seeing your foundation bottle empty so quickly. Sponges seem to drink more product than they apply. Silicone and microfiber sponges4 were designed specifically to solve this problem.

silicone sponges5 are non-porous and absorb almost no product, making them the most economical choice for saving foundation. Microfiber sponges use a fine fiber barrier that reduces absorption compared to foam, offering a buildable, brush-like finish.

![]()

When a brand wants to build a story around product economy or a unique application experience, these materials are fantastic options. They offer a clear point of difference from the standard PU sponge and can appeal to specific customer needs.

The Zero-Waste Promise of Silicone

A silicone sponge has a completely smooth, non-porous surface, usually made of silicone and encased in a flexible material like thermoplastic polyurethane (TPU). Because it doesn’t have any pores, it absorbs virtually zero makeup. You only need a small amount of product to achieve full coverage. This makes it a hero product for anyone who wants to maximize their liquid or cream formulas. The trade-off is in the technique; it requires patting and stippling motions to blend, as rubbing can cause streaks. They are also incredibly easy to clean and sanitize, which is a major hygiene benefit.

The Hybrid Power of Microfiber

Microfiber sponges are a fascinating innovation. They typically have a standard PU foam core, but the outside is coated with a layer of tiny, dense fibers, creating a velvet-like texture. This fiber barrier acts as a buffer, slowing down product absorption into the sponge’s core. It gives you more playtime to blend on the skin. I’ve found these sponges are amazing for both liquids and powders. They can apply foundation smoothly and then be used to set it with powder, almost like a sponge and a brush in one. They require very thorough cleaning, however, to ensure no residue is trapped in the fibers.

| Feature | Silicone Sponge | Microfiber Sponge |

|---|---|---|

| Product Absorption | Almost None | Low |

| Best For | Liquid/Cream Foundation | Liquid, Cream, & Powder |

| Finish | Full Coverage | Buildable, Airbrushed |

| Cleaning | Very Easy (Wipe Clean) | Requires Thorough Washing |

Microfiber sponges absorb more product than traditional PU sponges.False

The external fiber layer on a microfiber sponge creates a barrier that slows down absorption, meaning less product is wasted compared to a standard PU foam sponge.

Are Natural Cellulose & Sea Sponges a Good Eco-Friendly Choice?

Your brand is built on sustainability and natural ingredients. But you also need to provide tools that perform well. Natural sponges offer biodegradability but come with specific use cases and important hygiene considerations.

natural cellulose6 (from wood pulp) and sea sponges are biodegradable and very absorbent, making them excellent for facial cleansing and skincare application. For makeup blending, their high absorbency makes them less precise and more wasteful than PU sponges.

I often speak with founders of eco-conscious brands who are interested in these materials. They are a great fit for a skincare line or as a cleansing tool. However, I always caution them about the performance trade-offs when it comes to makeup application.

The Eco-Conscious Appeal

The main draw of these sponges is their origin and end-of-life. Cellulose sponges are derived from plant-based wood pulp fibers, and sea sponges are harvested from the ocean. Both are fully biodegradable, which is a powerful marketing story for a brand focused on reducing plastic waste. They appeal directly to the environmentally aware consumer. When sourced responsibly, they can be a truly sustainable alternative to synthetic tools.

Performance and Hygiene Trade-offs

The very quality that makes these sponges great for cleansing—high absorbency—makes them less ideal for applying foundation. They tend to soak up a lot of product, leading to waste. Their texture is also less uniform than a PU sponge, making a seamless, streak-free blend more difficult to achieve. Most importantly, because they are natural and hold so much water, they can become a breeding ground for bacteria if not dried completely and cleaned meticulously after every use. For a brand, it’s crucial to provide clear instructions on hygiene to prevent any issues.

| Feature | Cellulose Sponge | Sea Sponge |

|---|---|---|

| Source | Wood Pulp (Plant-Based) | Marine Animal |

| Best Use | Cleansing, Skincare | Cleansing, Body Washing |

| Biodegradable? | Yes | Yes |

| Hygiene Note | Must be dried fully to prevent bacteria | Must be dried fully; can harbor microbes |

How Do You Keep Your Makeup Sponges Hygienic and When Should You Replace Them?

You wash your sponge, but is it truly clean? A dirty sponge can harbor bacteria, leading to breakouts and poor makeup application. A simple, consistent routine is the solution for hygiene and performance.

For best results, clean your sponge after every use with a gentle soap and warm water. Squeeze it repeatedly until the water runs clear, then let it air dry completely in a well-ventilated area. Replace your sponge approximately every 3 months.

As a brand, educating your customers on proper tool care is a huge value-add. It ensures they have a good experience with your product and reinforces your commitment to quality and health. It’s a simple step that builds trust.

A Step-by-Step Cleaning Routine

Keeping a sponge clean is not complicated, but it must be done correctly.

- Wet the sponge thoroughly under warm running water.

- Apply a small amount of gentle soap, baby shampoo, or a dedicated sponge cleanser directly onto the sponge.

- Gently squeeze and massage the sponge to work the cleanser into a lather. You will see the makeup residue begin to rinse out.

- Rinse and squeeze repeatedly under running water until the water runs completely clear.

- Squeeze out all excess water and set the sponge on a clean, dry surface with good air circulation to dry completely. Never store a damp sponge in a closed bag or drawer.

The 3-Month Rule and Why It Matters

Most manufacturers, including us at Brushino, recommend replacing a makeup sponge every three months with daily use. This isn’t just a sales tactic. Over time, even with regular cleaning, bacteria can still build up inside the sponge. More visibly, daily use causes microscopic tears in the foam. These tears trap product and bacteria, and they compromise the sponge’s ability to blend smoothly. If you notice your sponge has permanent stains, a persistent odor, or is starting to tear or crumble, it’s time to replace it immediately, even if it hasn’t been three months.

| Hygiene Task | Recommended Action |

|---|---|

| Frequency | After every use |

| Method | Gentle soap and warm water |

| Drying | Air dry in an open, ventilated space |

| Replacement | Every 3 months, or sooner if damaged |

Which Sponge Material Is Best for Your Liquid, Cream, or Powder Makeup?

You want to promise your customers the perfect finish, whether it’s dewy or matte. But using the wrong sponge with a certain formula can make foundation look cakey or streaky. Matching the sponge to the makeup is key.

Use a damp hydrophilic PU sponge for a seamless, skin-like finish with liquid and cream foundations. For setting powders, a microfiber sponge or a dry SBR latex sponge works best. Silicone is ideal for applying full-coverage formulas with minimal product waste.

Helping your customers choose the right tool for their favorite formula is essential. When you’re developing a product line, think about the primary use case. Is your brand known for a dewy skin tint or a full-coverage matte foundation? The answer will guide your choice of sponge material.

Perfect Pairings for a Flawless Application

The interaction between the sponge material and the makeup formula determines the final result.

- Liquids & Creams: A damp PU sponge is the undisputed champion here. The moisture helps shear out the product for a natural, non-streaky finish.

- Powders: A microfiber sponge is excellent for powders. The fuzzy texture picks up loose or pressed powder and applies it with a soft, diffused look, perfect for setting makeup or for a gentle powder foundation application.

- Full Coverage: A silicone sponge is perfect for getting the most out of high-pigment formulas. Since it doesn’t absorb any product, you can build coverage exactly where you need it without waste.

Achieving Your Desired Finish: Dewy vs. Matte

The sponge can also influence the final finish. For a dewy, luminous look, applying foundation with a very damp PU sponge will help maintain the skin’s moisture and the formula’s radiance. For a more matte or satin finish, you can use a slightly less damp PU sponge or press and roll a dry microfiber sponge with setting powder over your foundation.

| Sponge Material | Best with Formula | Resulting Finish |

|---|---|---|

| Hydrophilic PU (Damp) | Liquid, Cream | Sheer to Medium, Dewy/Natural |

| Silicone | Liquid, Cream | Full Coverage, Natural |

| Microfiber | Powder, Liquid | Buildable, Soft Matte/Airbrushed |

| SBR Latex (Dry) | Powder | Medium to Full, Matte |

How Can You Verify ‘Latex-Free’ Claims and Source Allergy-Safe Sponges?

You need to guarantee your products are safe for all customers. A misleading "latex-free" claim can destroy your brand’s credibility and cause real harm. Knowing what to ask your supplier is crucial.

Always choose hydrophilic polyurethane (PU) for a guaranteed latex-free option. When sourcing, you must ask your manufacturer for material specification sheets to verify the composition. Avoid sponges simply labeled "non-latex" without specifying the material, and always avoid natural rubber (NR).

This is a non-negotiable for me when advising clients. Your customers’ safety comes first, and protecting your brand from liability is just smart business. One of my clients nearly sourced a batch of "non-latex" sponges that were actually a synthetic rubber blend. We caught it by requesting the material data sheet, saving them from a potential crisis.

Reading Between the Lines of Packaging

As a brand owner, you are responsible for the claims on your packaging.

- "Latex-Free": This claim should only be used if the product contains no natural rubber latex. The safest way to ensure this is by using 100% PU foam.

- "Hypoallergenic": This term is less regulated and generally means the product is less likely to cause an allergic reaction. A latex-free PU sponge is inherently hypoallergenic for most users.

- Material Disclosure: The best practice is to be transparent. Stating "Made from 100% Hydrophilic Polyurethane Foam" is clearer and more trustworthy than a simple icon.

Due Diligence for Brand Owners

Don’t just take a supplier’s word for it. As part of your sourcing process, you need to perform due diligence. Ask for a Material Safety Data Sheet (MSDS) or a Technical Data Sheet (TDS) for the raw material. This document will explicitly state the chemical composition and confirm whether it is PU, SBR, NBR, or something else. A reliable supplier will have no problem providing this documentation. This is one of the key pain points for brand founders, and a good manufacturing partner will make this process transparent.

| Sourcing Checklist | Action Required |

|---|---|

| Material to Choose | Hydrophilic Polyurethane (PU) |

| Material to Avoid | Natural Rubber (NR) |

| Documentation to Request | Material Safety Data Sheet (MSDS/TDS) |

| Wyraźne oznakowanie | "Latex-Free" and/or "100% PU Foam" |

What Are the Latest Innovations in Sustainable Makeup Sponge Materials?

You want your brand to be seen as an innovator and an eco-conscious leader. But "green" claims can often feel vague or hard to verify. New plant-based materials are changing the game, offering real, measurable sustainability.

The most exciting innovation is plant-based polyurethane7. Leading manufacturers are now creating bio-foams using renewable resources like sugarcane to replace a portion of the petroleum-based ingredients. These sponges maintain the signature bounce and performance of traditional PU while boosting your brand’s sustainability credentials.

This is a trend I’m incredibly excited about. It directly addresses the demand from both brands and consumers for more environmentally friendly products without sacrificing performance. It’s the perfect story for a modern beauty brand.

The Rise of Bio-Based PU

The concept is simple but powerful: replace a percentage of the fossil fuel-derived components in polyurethane with plant-derived alternatives. A prime example is Beautyblender’s BioPlush™ foam, which they report is made with 60% plant-based content from sugarcane. This is a significant step forward. It reduces the carbon footprint of the product and moves the industry toward a more circular economy. As a brand, offering a sponge made from renewable resources is a compelling and verifiable marketing claim.

How to Vet Sustainability Claims

"Greenwashing" is a real concern for conscientious brand owners. When a supplier offers you an "eco-friendly" sponge, you need to ask the right questions.

- What is the exact percentage of bio-based content? A vague claim of "contains plant-based materials" is not enough. Ask for a specific number.

- What is the source of the bio-based content? Is it sugarcane, corn, or another resource?

- Do you have any third-party certifications? While not always available, certifications can validate the claims.

A trustworthy partner will be transparent about the composition and provide the data to back up their claims. This allows you to confidently market your product’s sustainable features to your customers.

| Evaluating Eco-Sponges | Key Question for Your Supplier |

|---|---|

| Material | Bio-Based Polyurethane |

| Sustainability Claim | "Made with X% plant-based material" |

| What to Ask | "Can you provide documentation for the exact percentage and source of the bio-based content?" |

Conclusion

Choosing the right sponge material impacts performance, safety, and your brand’s identity. You now have the expert knowledge to source the perfect tool that your customers will love.

References

-

Understanding hydrophilic polyurethane foam is crucial for selecting the best makeup sponge for flawless application. ↩

-

Polyether-based PU offers better elasticity and durability, ensuring a high-quality sponge experience. ↩

-

Understanding latex allergies is vital for brands to avoid customer complaints and ensure safety. ↩

-

Microfiber sponges provide a unique texture that enhances blending and reduces product waste. ↩

-

Silicone sponges offer minimal product absorption, making them a cost-effective choice for makeup application. ↩

-

Natural cellulose sponges are biodegradable and eco-friendly, appealing to environmentally conscious consumers. ↩

-

Plant-based polyurethane represents a significant advancement in sustainable beauty products, appealing to modern consumers. ↩