Want to create a custom makeup brush1 but don’t know where to start? The process is full of pitfalls. This guide is your expert roadmap from idea to launch.

Design a custom makeup brush by first defining the desired finish. Then, select the matching fiber and head shape. Lock in density and shape during sampling, validate with application and cleaning tests, and specify certifications like FSC wood. Typical OEM minimums2 start at 5,000 pieces.

You now have the big picture. But real success is in the details. I’ve spent years in manufacturing, and I can tell you that every choice, from the fiber to the ferrule, impacts the final product. It’s a process I know well, from my early days in a mold factory to running my own company. Let’s break down how to make those choices correctly, starting with the most important question: what result do you want?

Taiki, a major OEM, states a minimum order quantity (MOQ) of 5,000 pieces for custom brushes.True

This is a public benchmark for enterprise-level OEM, useful for brands planning their first production run and budget.

All synthetic brush fibers are vegan and eco-friendly.False

While many synthetics are vegan, not all are eco-friendly. Some are petroleum-based. Look for recycled or bio-based synthetics for a more sustainable option.

How Do You Design for Brush Outcomes, Not Just Parts?

Choosing brush parts without knowing the final effect is a common mistake. This leads to prototypes that don’t perform as your customers expect. Learn to translate your desired makeup finish into specific material and shape choices.

Translate your desired finish into technical specs. For an airbrushed look, choose dense, kabuki-style synthetics. For soft powder diffusion, use soft, tapered domes. Lock in these density and weight tolerances during sampling to ensure consistent performance across all production batches.

I remember a client who wanted a "flawless foundation" brush. We didn’t just talk about PBT fibers. We prototyped three different densities and two head shapes to find the one that achieved that specific streak-free finish. You must think about the end-user experience first. The components are just the tools to get you there.

Mapping Finish to Fiber and Shape

Start with the makeup formula and the desired look. Is it a liquid foundation that needs to be buffed without streaks? Or a powder blush that needs a soft wash of color? The answer determines your starting point.

Defining Density and Geometry

Once you have a direction, you need to get specific. "Soft" isn’t a technical specification. You need to define fiber density3, length, and the geometry of the brush head. This is where working with an experienced manufacturer is key. They can translate your creative brief into a technical one.

| Desired Finish | Recommended Brush Head | fiber characteristics4 |

|---|---|---|

| Airbrushed Foundation | Dense, Flat-Top Kabuki | Premium Synthetic (PBT), High Density |

| Diffused Powder/Blush | Soft, Tapered Dome | High-Grade Natural Hair or Ultra-Soft Synthetic |

| Streak-Free Liquid | Flat or Duo-Fiber | Premium Synthetic, Medium Density |

| Precise Concealing | Small, Pointed or Flat | Firm Synthetic, Dense |

Dense, premium synthetic fibers excel for applying liquid and cream formulas.True

Their structure provides controlled pickup and smooth application, and they are more hygienic and durable than natural hair for these formulas.

The shape of the brush handle is purely for aesthetics.False

Handle ergonomics affect user control and comfort during application. Weight, balance, and grip are critical functional design elements that impact the user experience.

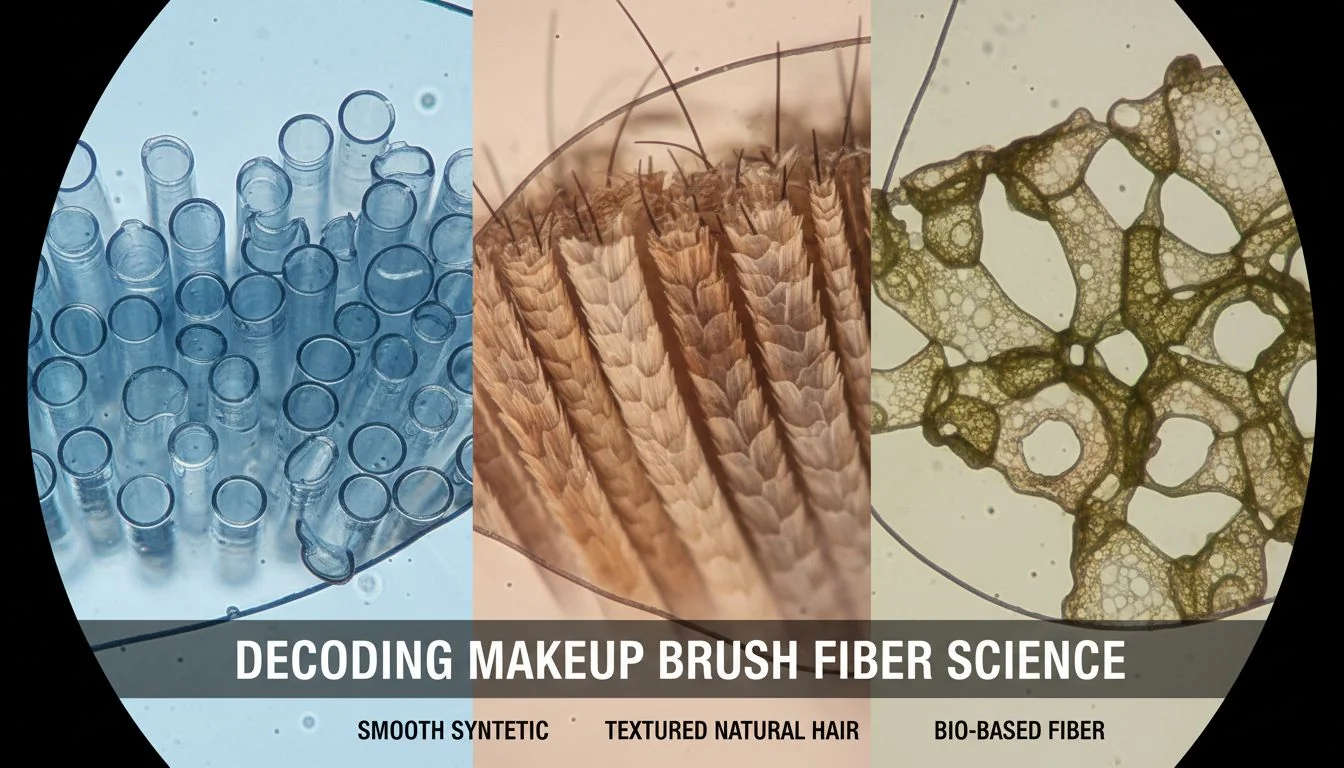

How Do You Decode Fiber Science for Your Formula?

The world of brush fibers is confusing. Choosing the wrong one means poor application, or even bacterial growth on the brush. You need to understand the key differences between vegan, antibacterial, and premium synthetic fibers to make the right choice.

Choose fibers based on your makeup formula. Premium synthetics like PBT are best for liquids/creams due to their consistency and hygiene. Vegan and bio-based fibers offer eco-friendly alternatives. Antibacterial options, verified by SGS reports, inhibit bacteria like S. aureus and E. coli.

A brand I worked with was developing a pro-level concealer brush. We opted for an antimicrobial-treated fiber. It was a key selling point for makeup artists who use brushes on multiple clients. But first, we had to validate the SGS lab reports. We needed to ensure the claims were solid and that the treatment didn’t make the bristles stiff or affect pickup.

Premium Synthetics for Performance

These are the workhorses of the industry, especially for liquid and cream products. Engineered fibers like PBT offer incredible consistency from batch to batch. They don’t absorb product like natural hair, are easier to clean, and dry faster.

The Rise of Vegan and Sustainable Fibers

Today, "vegan" is a minimum requirement for many brands. But sustainability goes further. You can now find fibers made from recycled materials or bio-based sources. These reduce the reliance on petrochemicals while aiming to match the softness of natural hair.

The Value of Antimicrobial Treatment

antimicrobial fibers5 are treated to inhibit the growth of common bacteria between cleanings. This is a powerful feature for brushes used around the eyes and lips, or for professional kits. Always ask for the third-party test reports to back up these claims.

| Fiber Type | Best For | Key Benefits | What to Verify |

|---|---|---|---|

| Premium Synthetic (PBT) | Liquids, Creams | Consistent, Hygienic, Durable | Grade & Density |

| Natural Hair (Goat, etc.) | Powders, Blending | Superior Diffusion, Softness | Ethical Sourcing, Supply Stability |

| Antimicrobial Synthetic | Eye/Lip, Pro Use | Inhibits Bacterial Growth | SGS/Third-Party Test Reports |

| Bio-Based/Recycled Synthetic | All Formulas | Lower Environmental Impact | Performance, Durability |

Antimicrobial fibers can be treated to inhibit the growth of specific bacteria like S. aureus and E. coli.True

Manufacturers like Taiki and Gracedo offer fibers with patented treatments or inherent properties, backed by third-party lab tests like SGS.

Natural hair is always better than synthetic for powder brushes.False

While high-grade natural hair offers excellent diffusion, premium synthetics have evolved to mimic this softness and offer better consistency, durability, and ethically sourced options.

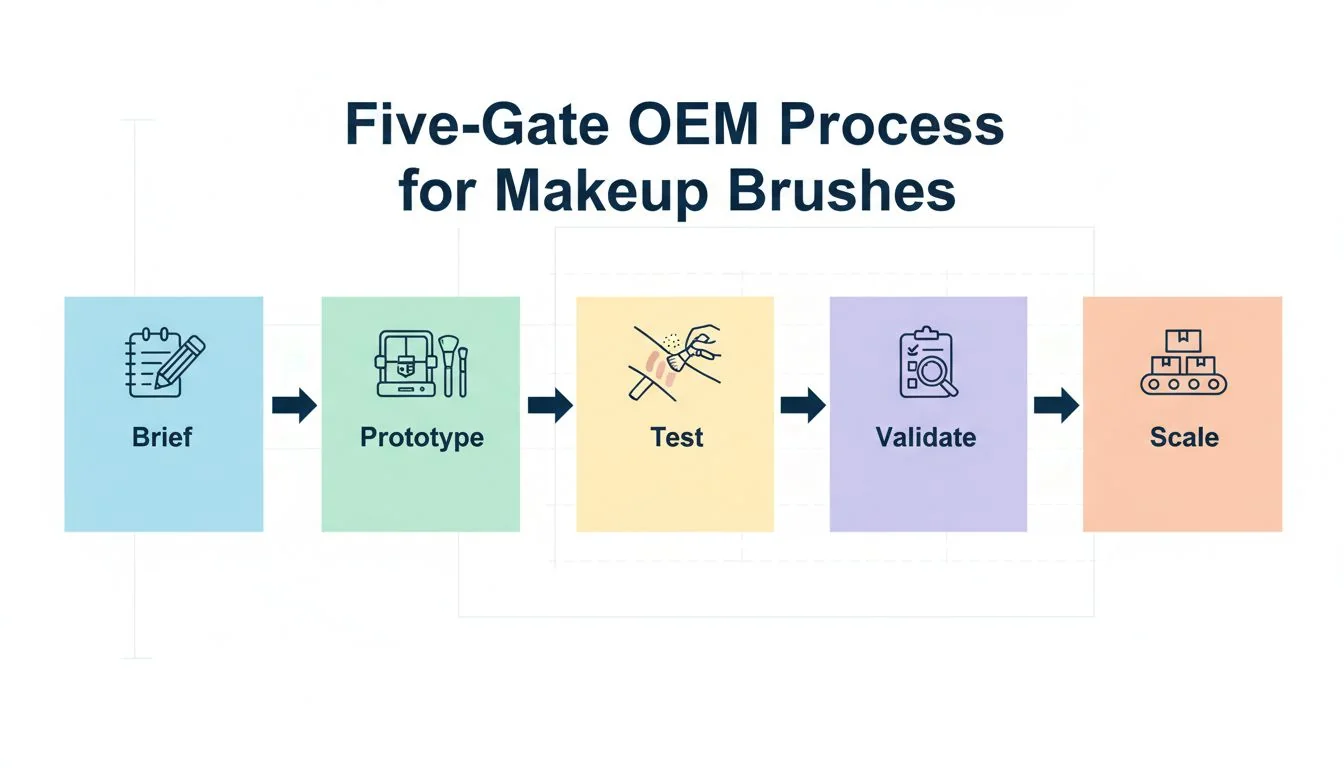

How Do You Manage the OEM Process in Five Gates?

Taking a brush design to mass production feels like a black box. Without a clear process, you risk delays, budget overruns, and quality issues. Use this five-gate OEM plan to move from your initial brief to large-scale production with confidence.

Use a five-gate process: Brief (define targets), Prototype (get samples with specs), Test (run application and cleaning cycles), Validate (approve with QC results), and Scale (move to production with inspections). This structured approach ensures you can sign off on quality at every stage.

I’ve seen projects fail because the validation step was rushed. A client approved a prototype visually, but we insisted on a 50-cycle cleaning test. The ferrule glue failed. Finding that before mass production saved them thousands of dollars and protected their brand reputation. A structured process is your best insurance policy.

Gate 1 & 2: From Brief to Prototype

This is where you define everything. Your target finish, formula compatibility, handle material, branding, and sustainability goals. Your manufacturer turns this brief into physical prototypes with documented specs for fiber weight, density, and shape.

Gate 3 & 4: Rigorous Testing and Validation

This is your job. Test the prototypes with your exact makeup formula. Does it perform? Then, abuse it. Run cleaning cycles. Do a bristle pull test. Check the ferrule bonding. Document everything. You approve the final prototype based on these test results, not just looks. This becomes your "golden sample."

Gate 5: Scaling with Confidence

Once you validate the pre-production samples, you authorize mass production. This stage should still include quality checks. Your manufacturer should perform incoming quality control on raw materials and a final inspection before the products ship.

| Gate | Action | Your Responsibility | Manufacturer’s Responsibility |

|---|---|---|---|

| 1. Brief | Define all product requirements | Provide a clear, detailed brief | Ask questions, confirm feasibility |

| 2. Prototype | Create initial samples | Review against the brief | Produce samples with spec sheets |

| 3. Test | Perform application & durability tests | Conduct rigorous, real-world testing | Provide samples for testing |

| 4. Validate | Approve final sample & QC criteria | Sign off on golden sample & tests | Document all approved specs |

| 5. Scale | Begin mass production | – | Implement QC, manage production |

A robust QC plan should include bristle retention pull tests and ferrule bonding checks.True

These mechanical tests go beyond visual inspection to ensure the brush is durable and won't shed or fall apart during use, which are common customer complaints.

Once you approve a prototype, the factory can immediately start mass production.False

After prototype approval, you must validate pre-production samples (PPS) from the actual tooling to confirm consistency before committing to the full run.

How Do You Look Beyond Aesthetics to Compliance, Sustainability, and Packaging?

A beautiful brush isn’t enough. Ignoring compliance, sustainability, and packaging can lead to shipping damage, customs issues, or a product that doesn’t align with your brand values. You must integrate these critical elements into your design from the start.

Go beyond looks by specifying compliance and sustainability. Request certifications like FSC for wood and consider eco-materials like bio-resins. Design protective packaging with hair covers to prevent bristle damage during shipping and preserve the brush’s performance for the end-user.

We once had a shipment of beautifully designed brushes arrive with all the heads bent. The packaging was just a simple box. Now, I always insist on individual bristle guards and structured inserts. It costs a little more per unit, but it protects the entire investment and ensures a perfect customer experience.

Navigating Compliance and Certifications

Your manufacturer should be able to provide proof of their factory audits. These certifications tell you about their quality management systems and ethical labor practices. This is a crucial step in vetting a partner.

| Audit/Certification | What It Means | Why It Matters |

|---|---|---|

| ISO 9001 | Quality Management System | Ensures consistent processes and quality. |

| ISO 14001 | Environmental Management | Shows commitment to reducing environmental impact. |

| BSCI / SMETA | Social & Ethical Audits | Verifies fair labor practices and safe working conditions. |

| FSC | Forest Stewardship Council | Confirms wood is from responsibly managed forests. |

Sustainable Choices That Perform

Sustainability is more than a buzzword. You can make real choices that reduce environmental impact. Consider ferrule-less designs that use a single piece of wood, or handles made from bio-resins. Ask for recycled or bio-based synthetic fibers. Most importantly, ensure these eco-choices still pass your durability and performance tests.

Packaging That Protects

Your packaging has two jobs: sell the product and protect it. For brushes, protection is critical. The delicate shape of the brush head must be preserved from the factory to the customer’s hands. Use protective covers for the bristles and structural box inserts to prevent crushing during transit.

Supplier audits like ISO 9001, BSCI, and SMETA are important indicators of a factory's quality management and ethical standards.True

These certifications show a commitment to standardized processes and social responsibility, which helps you vet potential manufacturing partners.

Eco-friendly materials always compromise brush performance and durability.False

Modern bio-resins, recycled fibers, and well-designed wooden handles can match or exceed the performance of traditional materials when properly engineered and tested.

Conclusion

Designing the perfect brush means linking finish to materials, using a gated QC process, and considering compliance. This guide gives you the framework to manufacture with confidence and quality.

References

-

Explore the essential steps and considerations for designing a custom makeup brush that meets your specific needs. ↩

-

Learn about the minimum order quantities required for custom brush production and how it impacts budgeting. ↩

-

Understanding fiber density is crucial for achieving the desired makeup application results. ↩

-

Understanding fiber characteristics helps in selecting the right brush for specific makeup applications. ↩

-

Discover how antimicrobial fibers can enhance hygiene and performance in makeup brushes. ↩