Featured image:

The holiday season is a huge opportunity. But you’re worried about missing the launch window for your seasonal brush set1. A delayed launch means lost sales and wasted inventory.

You can launch Halloween brush sets in 6–10 weeks. The key is to use stock components, approve samples in 7–10 days, and run packaging production2 in parallel with brush manufacturing. Inventory should land by early November to capture peak holiday demand, with most OEMs requiring a 1000-unit MOQ.

Hitting a tight seasonal deadline feels stressful. I’ve seen many brand founders, just like you, feel overwhelmed by the timelines. When I first started on the factory floor, I saw firsthand how a single delay in packaging could cause a brand to miss the entire holiday sales window. It’s why I’m so passionate about creating a clear, transparent roadmap for my clients. It is possible to move fast without sacrificing your brand’s vision. You just need a solid plan and a partner who understands how to manage each step efficiently. Let’s break down exactly how you can do it.

Generate Claims

Buy Now, Pay Later (BNPL) usage for online shopping is highest among Baby Boomers.False

Industry data shows BNPL is most popular with younger generations, with Millennials (39%) and Gen Z (38%) leading usage, making it a key tool for brands targeting these demographics.

The U.S. online holiday sales for 2024 are projected to grow by over 8% year-over-year.True

Forecasts predict U.S. holiday online sales will reach approximately $240.8 billion, an 8.4% increase from the previous year, highlighting the massive opportunity for seasonal products.

Fast Turn, Low Risk: How do you hit 6–10 week OEM timelines for Halloween brush sets?

Long lead times feel incredibly risky for a seasonal product. Every day of delay eats into your selling window and potential profit, leaving you anxious about your launch.

To hit a 6–10 week timeline, you must use a strategy of parallel workflows. This means pre-stocking standard components like fibers and ferrules, approving artwork on day one, and printing packaging at the same time handles are being finished. Book your QC slot early to avoid delays.

To make a 6–10 week timeline a reality, we have to eliminate idle time. Many brands think of production as a linear process: finish step 1, then start step 2. This is where delays happen. The fastest way is to run multiple steps in parallel. For example, as soon as you approve the design, we can start two processes at once: producing the brush heads and handles, and printing your custom packaging. This simple change can cut 1-2 weeks off the schedule. I always advise my clients to finalize their packaging dielines right at the start. This allows the printing to begin immediately. We also pre-book a slot with the quality control3 team before the pilot run is even finished. This ensures there’s no waiting around for an inspector. It’s all about proactive scheduling.

Key Production Stage Benchmarks

| Stage | Typical Duration | How to Speed It Up |

|---|---|---|

| Sampling | 7–14 Days | Provide clear artwork; use stock components. |

| Produção em massa | 30–35 Working Days | Approve pilot run quickly; run parallel workflows. |

| Packaging | 2–3 Weeks | Use modular options (e.g., stock box + custom sleeve). |

| Quality Control (QC) | 1–2 Weeks | Pre-book your QC inspection slot. |

Generate Claims

Skipping the sample approval stage is a safe way to save 1-2 weeks on a tight deadline.False

Skipping samples is extremely risky. It can lead to mass production errors in color, shape, or quality that are impossible to fix, costing more time and money in the long run.

Confirming your artwork-ready dielines on day one is critical for a fast-turn launch.True

Finalizing dielines immediately allows packaging production to start in parallel with brush manufacturing, which is a core strategy for cutting down the overall lead time.

Seasonal Packaging That Ships On Time: What are your modular options, SLAs, and compliance needs?

You’ve designed beautiful, intricate custom packaging4. But you hear it’s the biggest cause of production delays. Now you’re worried your perfect box won’t arrive until after Halloween.

Use modular packaging5, like a stock box with a custom-printed sleeve, to cut 1–2 weeks from your timeline. Confirm your supplier’s certifications (FSC, ISO) early and ensure all documents (MSDS, COA) are ready for a smooth export process. This gets your product ready for on-time shipping.

When it comes to seasonal launches, packaging is where timelines get stretched. A fully custom-shaped box looks amazing, but it requires new tooling and extensive testing, which adds weeks to the schedule. For speed, I always recommend a modular approach. This means we use a high-quality "stock" component, like a standard tin, a paper box, or a pouch that we already have available. Then, we focus all the customization on a printed sleeve, a sticker, or a tag. You still get a unique, branded look that feels special for the holidays, but we skip the long development time for the core structure. It’s a smart trade-off that gets you to market faster. At the same time, we must prepare for compliance. Retail partners and customs will ask for documents. Having your ISO, BSCI, or FSC certificates and material safety data sheets (MSDS) ready from the start prevents last-minute holdups at the port.

Packaging Customization vs. Lead Time

| Customization Level | Description | Typical Lead Time Impact |

|---|---|---|

| Low (Fastest) | Stock box/pouch + custom sticker/tag | Adds 3-5 days |

| Medium (Balanced) | Stock box + custom-printed sleeve | Adds 1 week |

| High (Slowest) | Fully custom die-cut box or unique shape | Adds 3-4 weeks |

Generate Claims

FSC certification only matters if you are selling in Europe.False

FSC (Forest Stewardship Council) certification is globally recognized and increasingly demanded by retailers and consumers in the U.S. and other markets who prioritize sustainability.

Using a stock tin with a custom-printed paper sleeve is an effective way to reduce packaging lead time.True

This modular approach leverages a ready-made component (the tin) and only requires printing for the sleeve, avoiding the longer timelines associated with creating a fully custom-shaped box.

MOQ Tiers That Protect Cash Flow: How can you forecast with BNPL and discount elasticity?

High MOQs for a seasonal product are scary. You’re forced to tie up a lot of cash in inventory that has a very short selling season, risking major losses if it doesn’t sell through.

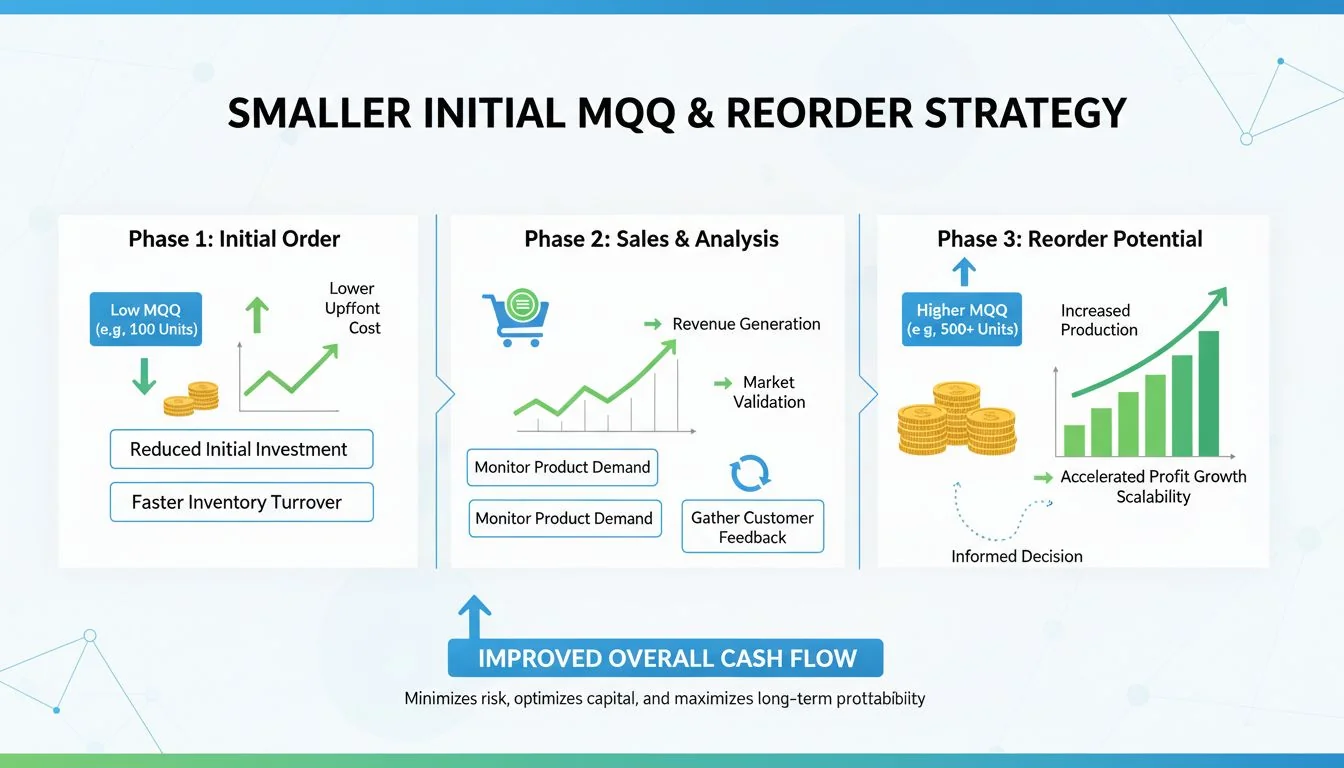

Use holiday sales data6 to make a smarter bet. With typical MOQs at 1000–2000 sets and promotions around 30%, model your demand carefully. The rise of BNPL can support a higher price point. Start with a smaller initial batch and plan for a fast reorder if sales take off.

For founders of independent brands, cash flow is everything. A 2,000-set MOQ7 on a Halloween-themed product can feel like a huge gamble. So, let’s use data to make it a calculated risk. We know that cosmetic deals get very competitive around Cyber Week, with discounts often hitting 30%. You need to build this into your pricing from day one to protect your margin. We also know that BNPL (Buy Now, Pay Later) is huge with Millennial and Gen Z shoppers, driving nearly $18.5 billion in spending. This data tells us two things: your customers are looking for deals, but they are also willing to purchase higher-ticket items if they can pay in installments. This means you can create a premium, higher-priced set. My advice is to negotiate an MOQ that protects your cash, even if the unit price is slightly higher. Launch with 1,000 sets. If your click-through and conversion rates are strong by mid-October, you can place a fast replenishment order via air freight.

MOQ Tiers & Cost Planning

| MOQ Tier (Sets) | Typical Unit Cost | cash flow8 Impact | Strategy |

|---|---|---|---|

| 1,000 | Highest | Low Initial Outlay | Test the market; plan for reorders. |

| 2,000 | Medium | Moderate Outlay | For brands with some sales history. |

| 5,000+ | Lowest | High Initial Outlay | For established bestsellers, not new seasonal items. |

Generate Claims

A 5% discount is enough to be competitive during the Cyber Week sales period.False

Industry data shows that for categories like cosmetics, discounts during Cyber Week are commonly around 30% to attract deal-sensitive holiday shoppers.

Planning for a 30% promotional discount is a realistic way to model profitability for a holiday launch.True

Given the competitive nature of holiday sales, building a 30% discount into your cost and pricing structure from the start is a smart strategy to ensure you remain profitable.

Sample-to-Launch Backward Plan: What is your week-by-week calendar to land by early November?

"6–10 weeks" is just a number. Without a concrete, week-by-week plan, it’s easy to miss a small deadline that pushes your entire launch back, causing you to miss the peak sales window.

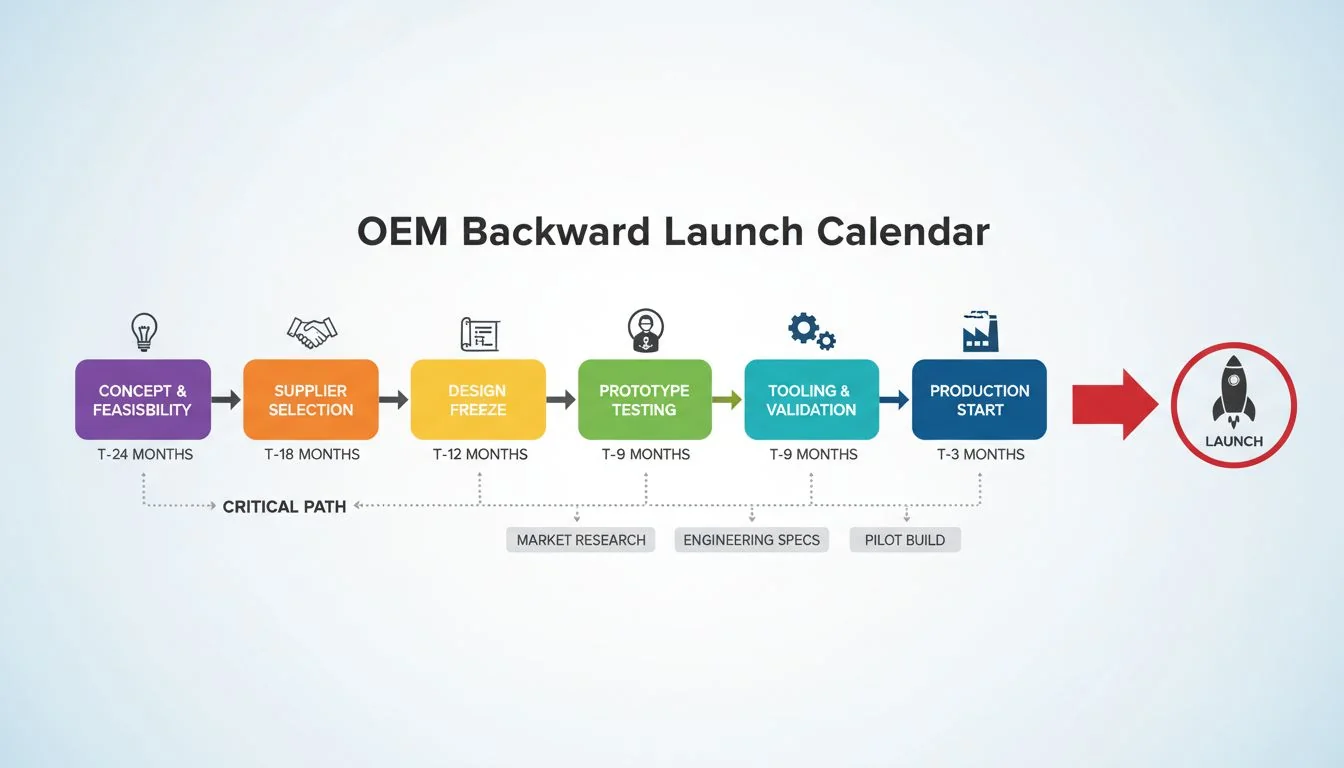

Here is a backward calendar you can use. To get inventory by early November, you must lock in your concept by late July. This allows time for samples in August, production in September, and shipping in early October.

A backward plan is the most powerful tool for an on-time launch. Instead of starting from today and moving forward, we start with your non-negotiable deadline—inventory in your warehouse by early November—and work backward. This immediately shows you the critical path and highlights key deadlines. If your product needs to be on a boat by the first week of October, that means production and QC must be finished by the end of September. This tells you that mass production must start by mid-September, which means your final approved sample needs to be in your hands by the end of August. Working this way removes all the guesswork. It also builds in checkpoints. For example, if your sample approval is delayed by a week in August, you know you need to have a conversation with your supplier about switching from ocean to air freight to still hit your deadline. This calendar turns a stressful process into a manageable checklist.

Your Backward Launch Calendar to Land by Early November

| Week | Milestone | Key Actions & Deadline |

|---|---|---|

| Week 10 | Inventory Arrives | Product in warehouse, ready for fulfillment. (Early November) |

| Week 6-9 | Freight & Logistics | Ocean freight transit (3-4 weeks). (Ship by Early October) |

| Week 5 | Final QC & Packing | Final inspection, pack-out, and prep for shipping. (End of September) |

| Week 3-4 | Produção em massa | Full production run of approved design. (Mid-September) |

| Week 2 | Pilot Run & Approval | Small pilot run to confirm quality before mass production. (Early September) |

| Week 1 | Aprovação de amostras | Final sign-off on physical samples. (End of August) |

| Before Week 1 | Concept & Design Lock | Finalize brush specs and packaging artwork. (Late July) |

Generate Claims

Air freight and ocean freight have similar transit times and costs.False

Air freight is significantly faster (days vs. weeks) but also much more expensive than ocean freight. It's typically used as a backup option to meet tight deadlines.

To ship by ocean freight in early October, mass production should be completed by the end of September.True

This timing accounts for final QC, packing, and transport to the port, ensuring the shipment leaves on schedule to arrive in North America or Europe by early November.

Conclusion

A fast seasonal launch is achievable. With a clear backward plan, smart modular choices, and a transparent OEM partner, you can confidently get your product to market on time.

References

-

Explore effective strategies for launching seasonal brush sets to maximize sales and meet deadlines. ↩

-

Learn about best practices in packaging production to ensure timely delivery and brand integrity. ↩

-

Effective quality control is essential for maintaining product standards and avoiding costly errors. ↩

-

Explore the challenges of custom packaging and how to mitigate delays in product launches. ↩

-

Discover how modular packaging can streamline production and reduce lead times. ↩

-

Utilizing holiday sales data can significantly enhance your product launch strategies and forecasting. ↩

-

Understanding MOQ helps in managing cash flow and inventory effectively during product launches. ↩

-

Managing cash flow is critical for sustaining operations and minimizing risks during product launches. ↩