Your brand wants to be sustainable, but the beauty industry’s packaging waste is overwhelming. Regulations are tightening, and your customers are demanding change. Here’s how to build a sustainable brush program1.

Sustainable makeup brush packaging reduces waste by using mono-material molded fiber trays2, FSC bamboo handles, and PCR plastics. Refills and reusable cases can cut packaging CO₂ by about 60% while meeting new EU regulations.

The beauty industry has a packaging problem. We generate around 120 billion units of packaging every year, and the sad truth is that most of it—about 95%—is never recycled. When I started my journey on the factory floor, I saw this waste firsthand. It’s why I’m so passionate about helping brand founders like you find better, smarter solutions. It’s not just about being "green"; it’s about building a brand that is ready for the future and earns customer trust. Let’s walk through the practical steps to make your brush packaging truly sustainable, from the raw materials to the unboxing experience.

The beauty industry generates over 120 billion packaging units annually.True

Multiple industry reports and environmental groups cite this figure, highlighting the scale of packaging waste in the cosmetics sector.

All bamboo is inherently sustainable, regardless of how it is sourced.False

Sustainability depends on responsible forestry. Only bamboo with FSC (Forest Stewardship Council) certification guarantees it comes from a responsibly managed forest that provides environmental, social, and economic benefits.

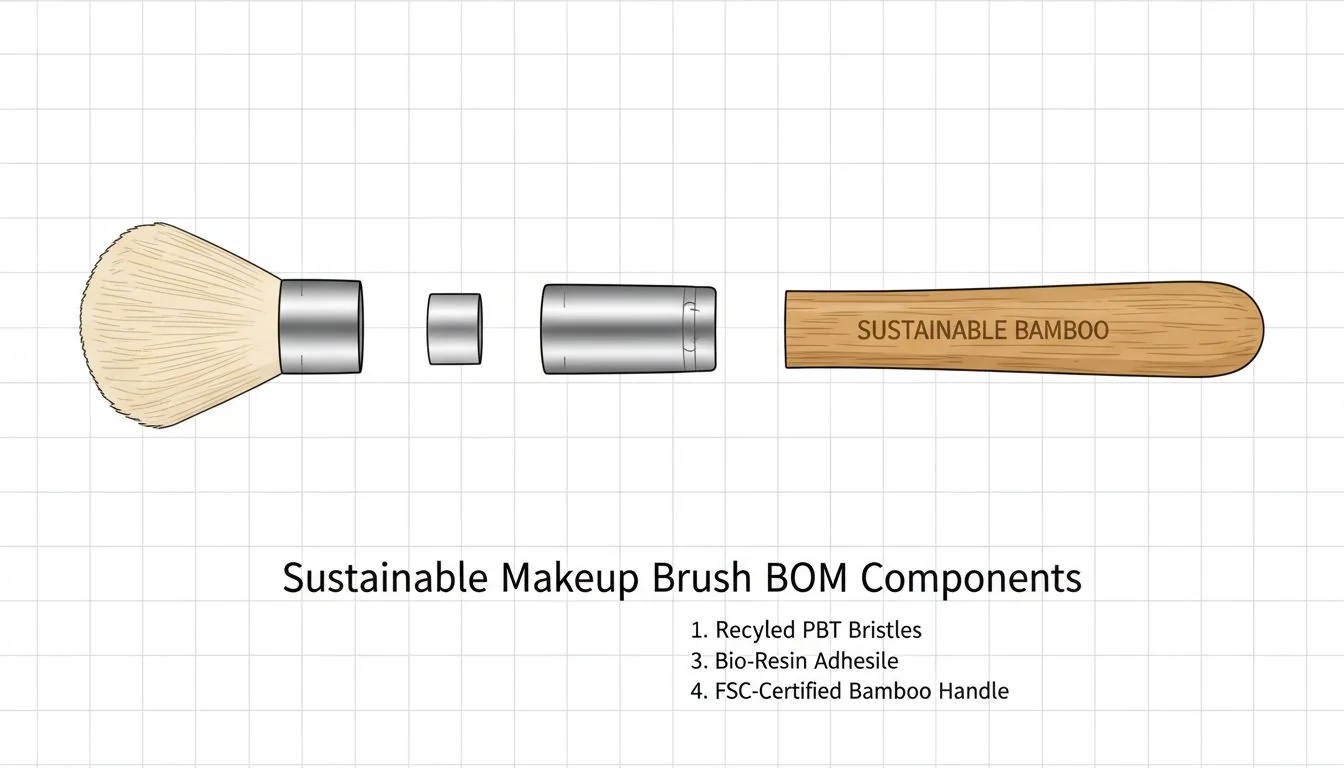

How Can You Spec a Truly Sustainable Makeup Brush Bill of Materials (BOM)?

Specifying a sustainable brush feels complex, and you worry one wrong material choice could undermine your eco-claims. The good news is that a few key decisions can make a huge impact.

To spec a sustainable brush BOM, choose high-grade synthetic PBT bristles, recyclable aluminum ferrules, and FSC-certified bamboo3 or recycled aluminum handles. Finish with water-based coatings and inks to align with circular design principles and upcoming EU regulations.

Building a sustainable brush starts with the Bill of Materials (BOM). Every single component matters. As a factory owner, I’ve seen how small material choices can add up to a big environmental footprint. But I’ve also seen how smart choices can create a product that is both high-performance and genuinely eco-conscious. It’s about breaking the brush down into its core parts and choosing the best option for each.

Bristles: The Vegan Advantage

The best choice here is a high-grade synthetic fiber like PBT or Taklon. These bristles are 100% vegan and cruelty-free, which is a non-negotiable for many consumers today. They also offer incredible performance and consistency that you just can’t get with animal hair. Importantly, we should pair them with water-based sizing agents instead of harsh, solvent-heavy chemicals.

Ferrules: Ditching Mixed Materials

The ferrule is the metal part that connects the bristles to the handle. The goal is to make it easily recyclable. Pure aluminum is a great choice because it’s widely recycled. Recyclable PP (polypropylene) is another option. The key is to avoid strong, mixed-material glues. I always push my clients toward designs that use a snap-fit or mechanical connection, which makes it easy for the consumer to separate the parts for proper disposal.

Handles: Choosing Your Foundation

For handles, FSC-certified bamboo is a fantastic renewable resource. The FSC certification is critical—it’s your proof that the material comes from a responsibly managed forest. Recycled aluminum is another excellent, durable, and infinitely recyclable option.

Coatings & Inks: The Finishing Touch

Finally, how you finish the handle matters. Avoid thick, multi-layer decorative films. Instead, use low-VOC, waterborne, or UV-cured coatings. For logos and labels, always spec water-based or vegetable-based inks. These small details reduce emissions and ensure the handle’s material can be properly recycled.

| Component | Sustainable Option | Why It Matters |

|---|---|---|

| Bristles | High-Grade Synthetic (PBT/Taklon) | Vegan, cruelty-free, consistent performance. |

| Ferrule | Recyclable Aluminum or PP | Enables mono-material recycling, avoids landfill. |

| Handle | FSC-Certified Bamboo or Recycled Aluminum | Uses renewable or recycled resources. |

| Coatings/Inks | Water-Based or Vegetable Inks | Reduces VOC emissions, aids recyclability. |

PBT synthetic bristles are not vegan.False

PBT (Polybutylene terephthalate) is a type of polyester, a synthetic polymer. It is not derived from animals, making it a 100% vegan and cruelty-free material for brush bristles.

Using water-based inks and coatings helps improve the recyclability of paper and bamboo packaging.True

Solvent-based inks and heavy coatings can contaminate the recycling stream. Water-based alternatives break down more easily during the repulping process, leading to higher-quality recycled fiber.

Can Refillable Brush Kits Really Cut CO₂ and Plastic Waste?

Single-use brush kits create a mountain of plastic waste that ends up in landfills. Your customers are tired of it, and new regulations are targeting this exact problem. Refill systems offer a proven solution.

Yes. Moving from rigid plastic clamshells to refillable systems with molded fiber trays can cut packaging-related CO₂ by over 60%. This strategy significantly reduces plastic use and helps brands prepare for EU PPWR compliance and lower future fees.

The data is clear: consumers are ready for a change. With refillable makeup sales surging 364% in just the first half of 2022, the demand is undeniable. This isn’t just a trend for skincare anymore; it’s moving across all of beauty. For brush brands, this is a massive opportunity. Instead of seeing packaging as a disposable cost, we can reframe it as a durable, reusable asset that builds brand loyalty. It’s a win for the planet, a win for the consumer, and a smart business move for you.

Quantifying the Impact: CO₂ and Plastic Savings

Let’s talk numbers. A typical brush set comes in a rigid plastic clamshell or a PVC box with a vacuum-formed tray. By switching to a reusable case with a simple molded fiber tray and a paper sleeve, you can eliminate tens of grams of plastic per unit. Life Cycle Assessments (LCAs) from brands that have made this switch show that refill formats can cut packaging-related CO₂ emissions by 60% or more with each "refill" cycle. The customer keeps the durable outer case or pouch and only replaces the brushes or the simple inner tray.

Aligning with EU PPWR

The European Union’s Packaging and Packaging Waste Regulation (PPWR) is a game-changer. It sets a target for all packaging to be reusable or recyclable by 2030 and aims to reduce per-capita packaging waste. By adopting refill-ready brush kits now, you are positioning your brand ahead of the curve. This not only ensures compliance but can also lead to lower Extended Producer Responsibility (EPR) fees in the long run, as you are putting less wasteful packaging onto the market. It’s about future-proofing your business.

Refillable packaging formats can reduce CO₂ emissions by more than 60% per use cycle.True

Multiple Life Cycle Assessments (LCAs) conducted by brands and packaging institutes confirm that when a consumer reuses a primary container and purchases a simple refill, the carbon footprint is reduced by 60-70% compared to buying a new, fully packaged product each time.

The EU PPWR only applies to plastic packaging.False

The EU Packaging and Packaging Waste Regulation (PPWR) applies to all packaging placed on the EU market, regardless of the material. It sets targets for recyclability, recycled content, and waste reduction for paper, glass, metal, and plastic.

How Do You Verify Sustainable Materials Like PCR and Bamboo?

You’ve sourced "sustainable" materials, but are they legitimate? Fake certificates and poor-quality materials can destroy your brand’s credibility and lead to a faulty product. A clear verification and QC process is your best defense.

Verify materials with official documentation: Global Recycled Standard (GRS) for PCR plastic and Forest Stewardship Council (FSC) for bamboo. Then, implement a QC checklist to test for performance, including strength, moisture content, and dimensional stability.

This is one of the biggest pain points I hear from brand founders. You place an order for "FSC bamboo" or "30% PCR" packaging, but what arrives feels flimsy or comes with no real proof. As a manufacturer, I believe transparency is everything. You have a right to see the documentation and know that the materials you’re paying for are exactly what you ordered. Here’s the simple QC process we use at Brushino to protect our clients.

PCR Plastic: Verification is Key

If a supplier claims a component contains Post-Consumer Recycled (PCR) plastic, ask for their GRS certificate. This document validates the chain of custody. You should also confirm the exact percentage of PCR content. For the packaging itself, especially secondary packs like mailer boxes, we always conduct drop tests and edge-crush tests to ensure the PCR content doesn’t compromise structural integrity.

FSC-Certified Bamboo: Beyond the Certificate

An FSC certificate is the first step, but it’s not the last. Bamboo is a natural material, so its quality can vary. We always specify a required moisture content (typically 8-12%) to prevent cracking or warping later on. We also perform coating adhesion tests and temperature/humidity cycling to confirm the handle’s dimensional stability. There’s nothing worse than a beautiful handle that cracks after a few months.

Molded Fiber: Fit and Finish

Molded fiber is perfect for trays, but precision is key. The tooling needs to be based on tight CAD tolerances to ensure your brushes fit perfectly. We test for compression strength (so it doesn’t crush during shipping), abrasion (to prevent fiber dust on your brush heads), and ink migration if you have printing.

| Material | Key QC Check | Why It’s Critical |

|---|---|---|

| PCR Plastic | GRS Certificate & Drop Test | To verify recycled content and ensure durability. |

| FSC Bamboo | FSC Certificate & Moisture Content | To verify responsible sourcing and prevent cracking. |

| Molded Fiber | Fit Tolerances & Abrasion Test | To ensure a premium feel and protect the product. |

GRS certification is only for textiles.False

While the Global Recycled Standard (GRS) is widely used in textiles, its scope is much broader. It can be applied to any product containing at least 20% recycled material, including plastics, paper, and metals used in packaging.

Molded fiber packaging is always 100% recyclable.True

Molded fiber, also known as molded pulp, is made from recycled paperboard and/or natural fibers like bamboo or sugarcane. It is a mono-material that can be recycled in standard paper and cardboard recycling streams worldwide.

What is ‘Design-for-Recycling’ for Beauty Accessories?

Your packaging might look eco-friendly, but can it actually be recycled? Complex designs with mixed materials and confusing labels often mean your beautiful packaging is destined for the landfill. Simple design choices can fix this.

design-for-recycling4 means using mono-materials like paperboard, eliminating plastic windows, using eco-inks that don’t contaminate the fiber, and adding smart labels like QR codes to provide clear disposal instructions. This ensures your packaging has the best chance at a second life.

"Design-for-recycling" is a simple idea: think about the end of your packaging’s life before you even start designing it. The goal is to make it as easy as possible for both the consumer and the recycling facility to process it correctly. I’ve seen so many well-intentioned brands create packaging that unfortunately fails at the final hurdle. A few simple rules can make all the difference and turn your packaging from waste into a valuable resource.

The Power of Mono-Material

The number one rule is to stick to a single material whenever possible. For a brush kit box, this means using only paper or paperboard. Avoid adding a plastic window, as this creates a mixed-material item that is difficult to separate and often rejected by recyclers. A clean, all-paperboard design is always the best choice. If you need a tray, use molded fiber, not plastic.

Inks and Labels that Don’t Contaminate

The type of ink and label you use matters. Heavy metallic foils and certain laminates can contaminate the paper recycling stream. It’s better to use direct printing with water-based or vegetable-based inks. If you must use a label, choose a "wash-off" adhesive that allows the label to separate cleanly during the re-pulping process.

Smart Labels for a Smarter Consumer

Recycling rules can be confusing and vary by location. You can help your customers do the right thing by adding a QR code to your packaging. This code can link to a page on your website with simple, clear instructions on how to separate and recycle each component. This not only increases recycling rates but also shows your customers that you are truly committed to transparency and sustainability. It builds trust and reinforces your brand’s values.

A plastic window on a cardboard box makes it non-recyclable.True

While technically the cardboard can be recycled if the window is removed, most consumers do not do this. Automated sorting facilities often divert mixed-material items like this to landfill to avoid contaminating the paper stream.

QR codes on packaging have been shown to increase consumer engagement with brand sustainability initiatives.True

Studies by the Digital Marketing Institute and others show that QR codes provide a low-friction way for consumers to access more information, and brands are successfully using them to share recycling guides, material provenance, and impact reports.

Conclusion

Making your makeup brushes sustainable is not just good for the planet; it’s smart business. By focusing on materials, refills, and design, you build a brand that customers trust.

References

-

Explore how sustainable brush programs can help brands reduce waste and meet consumer demands. ↩

-

Learn about the advantages of using mono-material molded fiber trays for eco-friendly packaging. ↩

-

Understand the importance of FSC certification in ensuring responsible bamboo sourcing. ↩

-

Explore the principles of design-for-recycling and how they enhance packaging sustainability. ↩