Planning your 2026 product line feels uncertain with shifting trends. You worry about making the wrong manufacturing choices. This analysis gives you the data-backed clarity you need to succeed.

In 2026, makeup brush manufacturing will be defined by vegan synthetic fibers1, growing APAC OEM capacity, and brand demands for faster sampling (7–14 days), low MOQs (300–1,000 sets), and full compliance (ISO 9001, REACH, FSC). The market is growing steadily, with APAC leading global share.

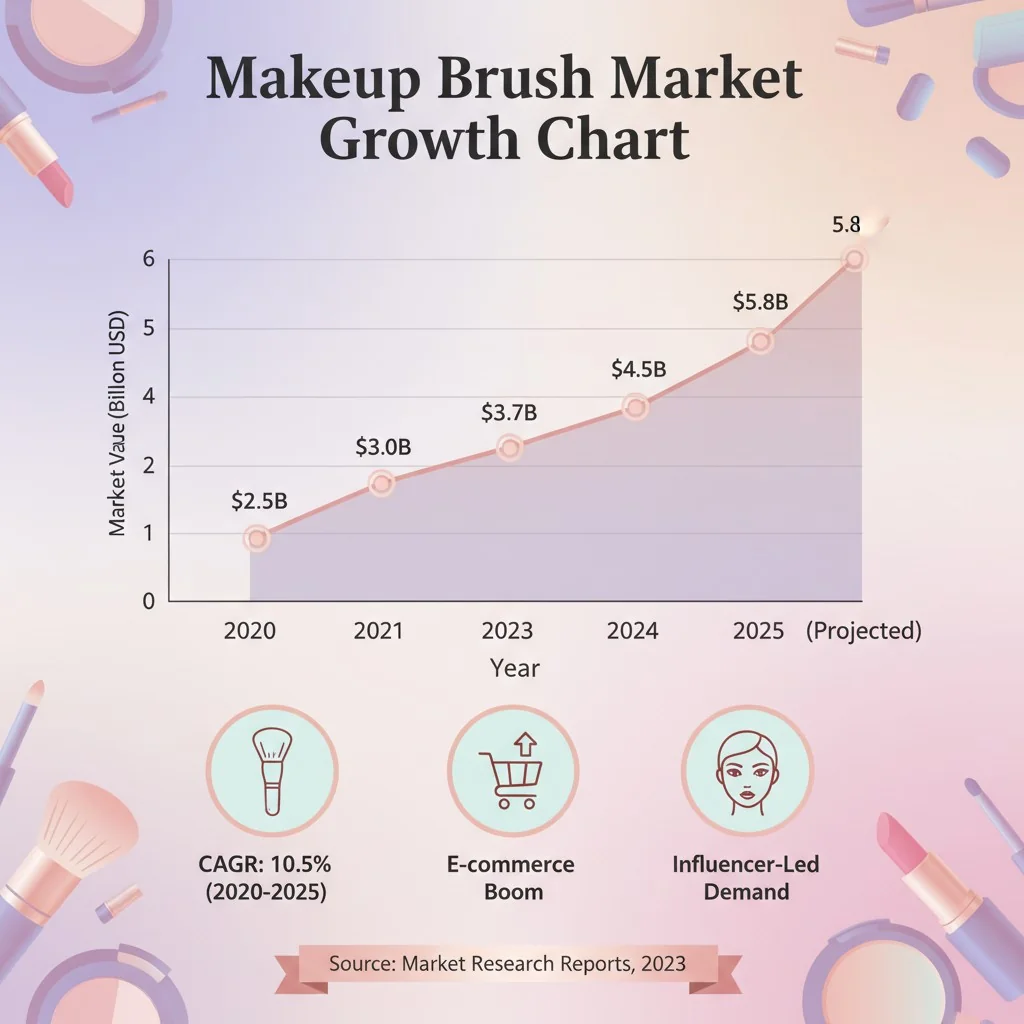

As a brand founder, you’re not just buying a product; you’re building an experience. The right brush can make or break a customer’s love for your makeup line. I started my career on the factory floor, so I’ve seen firsthand how a small detail in manufacturing can have a huge impact on quality. The global makeup brush market is complex, but the data shows a clear path forward. Different reports size the market differently, but they all agree on one thing: growth. To help you plan, I’ve put together a snapshot of the market landscape.

| Market Indicator | Data Point | Source(s) & Scope Note |

|---|---|---|

| Global Market Size (2024) | USD ~1.5B to ~3.5B | DataIntelo (brushes-only) vs. Verified Market Reports (brushes + tools) |

| Projected CAGR | 5–7% through 2030 | Verified Market Reports, 2025; GMInsights, 2025 |

| Regional Share (2023) | APAC: ~35–37% | Verified Market Reports, 2025; Accio, 2025 |

| Material Trend | Synthetic share to hit ~70% by 2030 | Accio, 2025; Mintel, 2025 |

This data tells a story of opportunity. The market is healthy, and the shift toward synthetic, cruelty-free products is not just a trend—it’s the new standard. Let’s break down what this means for you.

The global makeup brush market is expected to shrink by 2026 due to a decline in makeup usage.False

All major market reports project a compound annual growth rate (CAGR) of 5-7% through 2030, driven by e-commerce and product innovation.

The Asia-Pacific (APAC) region is the largest and fastest-growing market for makeup brushes.True

Market data shows APAC holds approximately 35-37% of the global market share and is a major hub for OEM/ODM manufacturing.

What Will Makeup Brush Buyers Demand Most in 2026? Vegan Fibers, Low MOQ, Faster Sampling?

Your customers want ethical products, but you need flexibility to grow your brand. High MOQs and slow sampling can kill your cash flow and ruin your launch schedule. Here’s what you need to demand from your factory partner.

Buyers will prioritize three things: high-performance vegan fibers, low minimum order quantities (MOQs) of 300–1,000 sets, and rapid development cycles. This includes prototypes in 7–14 days and mass production within 30–45 days, services readily available from flexible APAC factories.

When I work with brand founders like you, the conversation always comes back to balancing brand vision with business reality. You need brushes that perform beautifully and reflect your values, but you also need a supply chain that works for a growing business, not against it. The demands of 2026 are a direct reflection of this.

The Rise of Performance Vegan Fibers

The debate between natural and synthetic hair is over. Modern synthetic fibers, especially third-generation PBT/taklon, now match or even exceed the performance of animal hair. They are projected to capture nearly 70% of the market by 2030. Why? They offer lower absorption for liquid and cream products (meaning less wasted makeup), are easier to clean, and are inherently cruelty-free. When you write your tech pack, be specific. Ask for micro-tapered fibers to get that perfect balance of softness and powder pickup.

The Need for Speed and Flexibility

For a startup or indie brand, agility is everything. You can’t afford to tie up capital in thousands of units of a single brush. That’s why low MOQs2 are critical. I’ve seen flexible factories in China successfully support brands with orders as low as 300 to 1,000 sets. This allows you to test new designs without massive risk. Speed is just as important. A good partner should turn your design into a physical sample in 1-2 weeks. Once you approve it, production shouldn’t take more than 30-45 days. This speed helps you catch market trends and launch on time.

All makeup brush factories require a minimum order of 10,000 units, making it impossible for startups to enter the market.False

Many flexible OEM factories in the APAC region now offer low MOQs, often between 300 and 1,000 units, specifically to support indie brands and startups.

Synthetic brush fibers are projected to account for approximately 70% of the market share by 2030.True

This growth is driven by consumer demand for vegan/cruelty-free products and significant performance improvements in synthetic PBT/taklon fibers.

How Are Professional-Grade Makeup Brushes Manufactured? A Step-by-Step, QC-Verified Process?

You’re worried about getting consistent quality when your factory is thousands of miles away. A single bad batch can damage your brand’s reputation and lead to negative reviews. Understanding the manufacturing process helps you set clear, verifiable quality standards.

Professional brushes are made through a multi-stage process: fiber preparation and shaping, ferrule attachment and gluing, handle finishing, and final quality control3. Key QC checks include glue pull-out strength (>20N), shedding tests (<3 fibers per 100 strokes), and strict dimensional tolerances.

I’ll never forget the smell of the glue and the sound of the crimping machines from my first days in a brush factory. It taught me that a great brush isn’t an accident; it’s the result of a dozen small, precise steps done right. When you can’t be on the factory floor yourself, you need to know what to ask for. Here is a simplified look at how your brushes are made.

Step 1: Fiber Preparation and Shaping

It all starts with the fibers. For synthetics, this means extruding PBT or taklon filaments to a specific diameter (denier). These fibers are then crimped or texturized to create pockets that help pick up powder. Next, workers weigh out the exact amount of fiber for each brush and bundle it. The bundle is then placed in a mold and shaped—this is how you get a perfect flat-top kabuki or a fluffy tapered blender.

Step 2: Assembly and Gluing

The shaped bundle is inserted into the ferrule (the metal part). The ferrule is then crimped securely around the fibers. This step is critical for preventing shedding. Then comes the gluing. A strong, low-VOC epoxy is used to permanently bond the fiber bundle inside the ferrule. We always perform a pull-out test, where a machine pulls on the fibers to ensure the bond strength is above 20 Newtons. It’s a simple test that saves you from customer complaints about shedding.

Step 3: Finishing and Final QC

Finally, the ferrule-and-head assembly is glued onto the finished handle (e.g., FSC-certified wood). After the glue cures, each brush is trimmed, cleaned, and tested for shedding. Our internal standard is less than 3 loose fibers over 100 strokes. The last step is a visual check for any defects in the handle finish, logo printing, or brush shape before the brushes are packaged.

The color of a makeup brush handle has a significant impact on its performance.False

Handle color is purely aesthetic. The performance of a brush is determined by its fiber type, density, shape, and the quality of its assembly (gluing and crimping).

A standard quality control test for professional makeup brushes is the 'pull-out test,' which measures the force required to pull fibers from the ferrule.True

This test quantifies the strength of the glue bond. A common benchmark for face brushes is a pull-out strength greater than 20 Newtons to ensure durability and prevent shedding.

Which Certifications and Regulations Matter for Importing Brushes in the U.S./EU?

Navigating import rules for different countries is confusing and stressful. A mistake in compliance can get your shipment delayed, seized by customs, or result in fines, putting your entire launch at risk. Here is the essential checklist you need.

For U.S./EU imports, focus on ISO 90014 (quality systems), FSC (wood), and chemical safety like REACH (EU) and Prop 65 (California). For marketing, cruelty-free claims should be backed by programs like Leaping Bunny or PETA. These ensure factory reliability and product safety.

One of the biggest pain points I hear from brand founders is the fear of the unknown with regulations. You don’t have time to become a legal expert, but you need to protect your business. The key is to work with a factory that already has these systems in place. Think of certifications not as a headache, but as your insurance policy.

Factory-Level System Certifications

These tell you about the factory’s overall operations.

- ISO 9001: This is a quality management system. It means the factory has documented processes for everything from raw material inspection to final QC. It shows they are serious about consistency.

- ISO 14001: This is for environmental management. It shows the factory is working to reduce its environmental impact.

Product-Level Safety and Chemical Regulations

These relate directly to the materials in your brushes.

- REACH (EU): This regulation restricts hazardous substances in products sold in the EU. Your factory must provide reports showing that the paints, glues, and metals in your brushes comply.

- Proposition 65 (California): This requires businesses to provide warnings about exposure to certain chemicals. Your factory should be able to provide test reports confirming compliance or identify if a warning is needed.

- FSC (Forest Stewardship Council): If you use wooden handles, this certification ensures the wood comes from a responsibly managed forest.

Ethical and Marketing Claims

These are often brand-level certifications, but your factory must provide documentation to support them.

- PETA / Leaping Bunny: To claim your brand is "cruelty-free," these programs have strict requirements. Your manufacturer must provide affidavits confirming that no animal testing was involved in any part of the supply chain.

Any factory can claim its brushes are 'vegan' without any proof.False

While some factories may make unsubstantiated claims, true vegan compliance requires documentation confirming that no animal-derived ingredients are used in the fibers, glues, or coatings.

REACH is a European Union regulation that restricts the use of specific hazardous chemicals in consumer products, including makeup brushes.True

Compliance with REACH is mandatory for selling products in the EU and requires test reports for materials like coatings, adhesives, and metal ferrules.

What Are the Biggest Cost Drivers for OEM Makeup Brushes in 2026?

You need to set a realistic budget for your new brush line. Hidden costs and unclear pricing from suppliers can quickly destroy your profit margins and cause major stress. Understanding exactly where your money goes is the key to smart sourcing.

The biggest cost drivers5 are material choices (fiber grade, handle material), brush head design (fiber density and complexity), and order volume (MOQ). Finishing, packaging, and logistics also significantly impact the final unit price. Smart choices here are key to profitability.

When I develop a quote for a client, I’m not just giving them a single number. I’m breaking down the costs so they can make informed trade-offs. Your final price is a direct result of the decisions you make about materials and design. Let’s look at the main levers you can pull.

Material and Design Choices

This is where the bulk of the cost lies.

- Fibers: A basic synthetic fiber is cheaper than a premium, micro-tapered, antimicrobial-treated PBT fiber. More fiber (higher density) also directly increases cost.

- Ferrule: Aluminum is the standard, cost-effective choice. Brass is heavier, feels more luxurious, and costs more.

- Handle: A simple painted wood handle is the baseline. Using FSC-certified wood, bamboo, or recycled aluminum will increase the cost but adds a powerful marketing story.

Finishing, Packaging, and Logistics

These factors can add up quickly.

- Complexity: A simple round brush is easier and cheaper to produce than a complex duo-fiber or custom-angled brush head.

- Finishing: A multi-layer pearlized paint finish or laser-engraved logo costs more than a simple one-color spray and hot-stamp logo.

- Packaging: A simple polybag is cheap. A custom-printed, recycled paper box or a reusable pouch will add to the unit cost but also elevates the customer experience.

- MOQ: Lower order quantities always result in a higher per-unit cost because the factory’s setup costs are spread across fewer items.

As a rough guide, a simple synthetic eye brush might cost $0.60–$1.20 FOB, while a mid-tier face brush could be $1.80–$4.50. A premium, dense, or antimicrobial brush can easily go from $4.50 to $9.00 or more.

The most expensive part of any makeup brush is always the wooden handle.False

The biggest cost driver is typically the brush head, specifically the grade and amount (density) of the fibers used. A dense, premium synthetic head can cost much more than the handle.

Ordering a lower quantity (low MOQ) of brushes generally increases the cost per unit.True

This is because fixed costs of production setup, tooling, and administration are divided among fewer units, raising the price of each individual brush.

Conclusion

Understanding 2026 trends in materials, manufacturing, compliance, and cost empowers you. Now you can source brushes confidently and build a brand that is beautiful, sustainable, and built to last.

References

-

Explore how vegan synthetic fibers are revolutionizing the beauty industry with their performance and ethical standards. ↩

-

Discover how low minimum order quantities can help new brands manage costs and reduce risks. ↩

-

Learn about essential QC processes that ensure high-quality makeup brushes and customer satisfaction. ↩

-

Understand the significance of ISO 9001 certification in ensuring quality and consistency in production. ↩

-

Gain insights into how material choices and design complexity affect the pricing of makeup brushes. ↩