Sourcing makeup brushes feels like a guessing game with wildly different prices. This makes budgeting impossible and puts your brand’s reputation at risk if you choose wrong.

Makeup brushes are expensive because premium materials1 (fiber grade, ferrule metal), hand-shaped craftsmanship, and rigorous quality control deliver better pickup, blending, and durability. For brands, this investment reduces customer returns and builds loyalty, justifying the higher initial cost of goods.

Most articles just say "better materials cost more." But as a brand founder, you need to know what that really means for your unit cost and profit margins. When I started on the factory floor, I saw firsthand how a few cents’ difference in a component could completely change the final product. I’m going to take you behind the scenes and break down the real factory-to-shelf cost drivers. This is the knowledge that will empower you to spec your products with confidence and negotiate like an expert.

All natural hair brushes are cruelty-free.False

The term 'cruelty-free' for natural hair brushes can be complex. While some hair is collected from grooming or natural shedding, not all sourcing methods are guaranteed to be harmless. Brands must demand and verify documentation from their suppliers to truly claim cruelty-free status.

The metal part that holds the bristles is called a ferrule.True

The ferrule is the metal band that connects the bristles to the handle. Its material (e.g., aluminum, brass, copper) and how it's attached (crimping) are critical for a brush's durability.

How do materials change cost and performance?

Choosing between natural and synthetic fibers can feel like a gamble. If you pick the wrong one for your product, you could waste money on a brush that gives a terrible application.

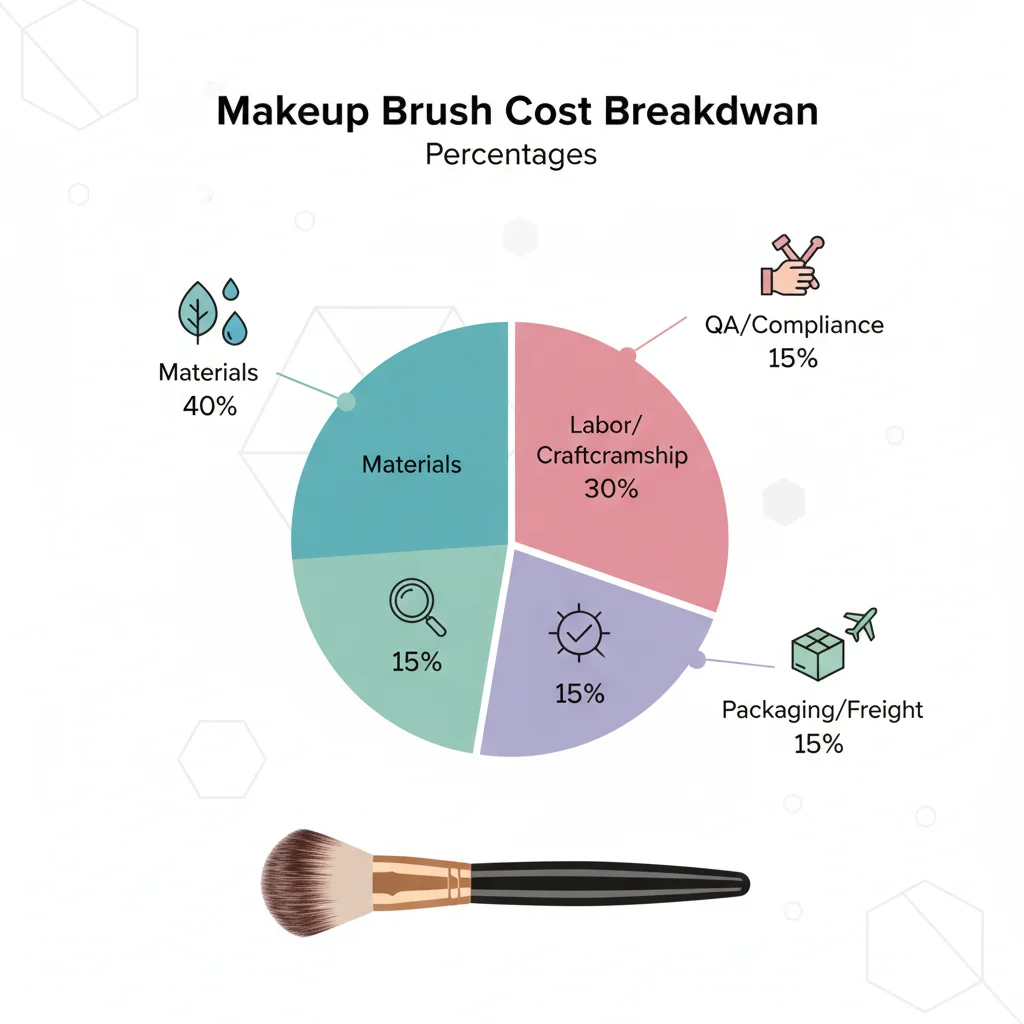

Materials are the single biggest factor, often driving 30-50% of a brush’s unit cost. High-performance synthetics are affordable and ideal for creams. Premium natural hairs cost more but offer unbeatable blending for powders. Your choice of handle and ferrule also adds up, directly impacting your final price.

When you’re developing a brush line, every component choice is a negotiation between cost and performance. From my experience, the most successful brands don’t just pick the cheapest option; they strategically map the material to the brush’s intended use.

Fiber, Ferrule, and Handle: The Cost Trio

The bristles get all the attention, but the ferrule and handle are just as important for quality and cost. A cheap, single-crimped aluminum ferrule might save you $0.10 per unit, but I’ve seen it lead to countless customer complaints about wobbly heads. A quality handle with a good finish feels better in the hand and resists damage from washing. It’s all connected.

Here’s a simple cost model I use to help clients understand their options:

| Component | Budget Option | Mid-Range Option | Premium Option |

|---|---|---|---|

| Bristles | Standard Synthetic (Nylon) | High-Grade Synthetic (Taklon) | Hand-Shaped Natural Hair (Goat) |

| Ferrule | Aluminum (Single Crimp) | Plated Brass (Double Crimp) | Plated Copper (Double Crimp) |

| Handle | Painted Poplar Wood | Lacquered Birch Wood | FSC-Certified Hardwood |

| Est. Unit Cost | $0.50 – $1.50 | $1.50 – $4.00 | $4.00 – $8.00+ |

| Best For | Entry-level kits, liquids | Core line, creams/powders | Luxury lines, powder blending |

This table shows how quickly costs can climb. Your job is to find the sweet spot that delivers the performance your customers expect at a price point that works for your brand.

Taklon is a type of natural hair.False

Taklon is a high-quality, 100% synthetic polyester fiber. It's known for being very soft, hypoallergenic, and is a popular choice for vegan and cruelty-free makeup brushes.

The density of bristles in a brush affects its performance and cost.True

A denser brush contains more individual fibers. This increases material cost but generally provides better product pickup and a more opaque application, especially for foundation and powder brushes.

Are pro brushes worth it for brands and pros?

You see "professional grade" on so many products, but is it just a marketing buzzword? For a brand owner like you, this question isn’t about a single purchase—it’s about your brand’s long-term return on investment.

Yes, for brands and professional makeup artists, they are an essential investment. Pro brushes are engineered for extreme durability under constant, heavy use and frequent washing. This means fewer replacements for artists and, crucially for your brand, fewer customer returns, better reviews, and a stronger reputation.

When I supply makeup schools, the first thing we discuss is the Total Cost of Ownership (TCO). A cheap brush might seem like a good deal upfront, but if you have to replace it twice a year, you’ve lost any initial savings. For your brand, this same logic applies to customer satisfaction.

The ROI of Durability and Design

A brush that fails—bristles shedding, the head wobbling, the handle cracking—creates a negative brand experience. This leads to returns, bad reviews, and lost customers. Investing in better construction is a form of insurance for your brand’s reputation. For example, using a double-crimped copper ferrule with strong epoxy glue costs more, but it virtually eliminates the risk of the brush head detaching.

Ergonomics for a Better Experience

Professional brushes are also designed for performance and comfort. A well-balanced handle with an ergonomic shape reduces fatigue for a makeup artist who uses it all day. For your customer, it just feels better and more controlled in their hand. These small details signal quality and justify a premium price point. A makeup school I work with told me their annual brush replacement order dropped by 40% after they switched to our brushes with lacquered hardwood handles and double-crimped ferrules. That’s a real, measurable ROI.

Ergonomic brush handles are just a gimmick.False

Ergonomics in brush design relates to balance, weight, and shape. For professionals who use tools for hours, an ergonomic handle can reduce hand fatigue and improve application control, making it a functional feature, not a gimmick.

A 'double-crimped' ferrule is more secure than a single-crimped one.True

Crimping is the process of physically pressing the metal ferrule to secure the bristles and handle. A double crimp provides two points of pressure, creating a much stronger and more durable bond that prevents the brush head from loosening over time.

Why do similar shapes vary in price?

You’ve seen it before: two tapered blending brushes that look almost identical, but one supplier quotes you $1 and another quotes $5. It’s confusing for you and hard to explain to your customers.

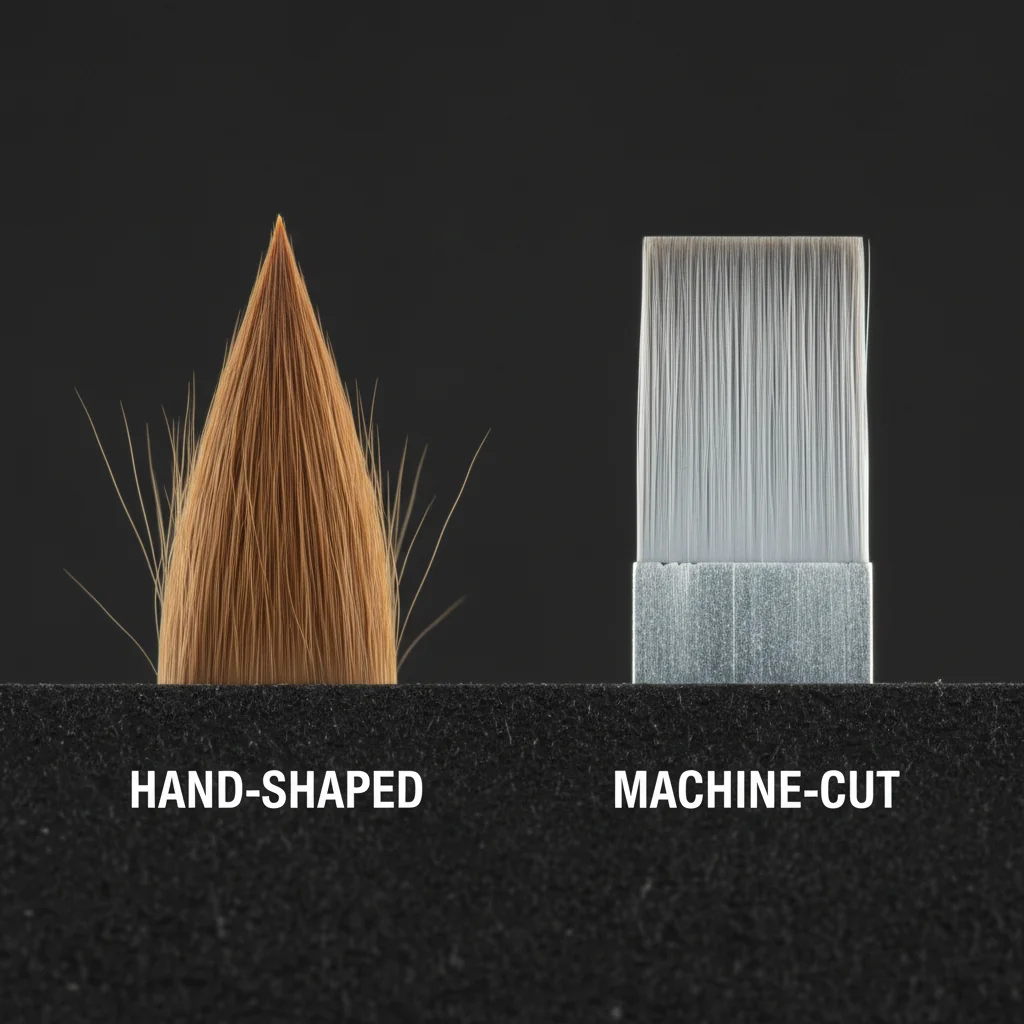

The price difference comes from invisible craftsmanship and material specs. The cheaper brush likely has machine-cut bristles, a lower bristle density, and a simple glued assembly. The expensive one almost certainly features hand-shaped tips for softness, a denser bundle for better blending, and a securely double-crimped ferrule2.

On the factory floor, I learned to spot the difference in seconds. It’s all in the tiny details that add up to a huge difference in performance and cost. These details are what separate a disposable tool from a long-term investment for your customer.

Craftsmanship: Hand-Shaped vs. Machine-Cut

This is one of the biggest differentiators in premium brushes. To create a hand-shaped brush head, an artisan gathers the bristles and gently taps them into shape in a mold, preserving the natural, soft, tapered tip of each fiber. This is why they feel so soft and excel at diffusing powder. A machine-made brush bundle is simply gathered and cut flat by a machine, which creates blunt, scratchy ends. Hand-shaping is a skilled, manual process, and that labor cost is reflected in the price.

Density, Assembly, and Quality Control

Beyond the tips, the sheer number of bristles matters. A dense brush picks up more product and provides a smoother application, but it also uses more raw material, increasing the cost. Finally, the assembly process—using high-quality glue and double-crimping the ferrule—adds manufacturing steps and time. Rigorous Quality Assurance (QA) to check for shedding and secureness also adds cost, but it prevents defective products from ever reaching your customer.

All synthetic brushes feel scratchy.False

Modern synthetic fiber technology has advanced significantly. High-grade synthetic fibers, like proprietary Taklon blends, can be extruded to be incredibly thin and soft, often mimicking the feel of natural hair while remaining vegan and easier to clean.

Hand-shaping a brush head is a more expensive process than machine-cutting.True

Hand-shaping requires a skilled artisan to manually arrange and shape the bristles to form a perfect head without trimming the tips. This labor-intensive process increases production time and cost but results in a softer, higher-performing brush.

Do premium brushes last longer?

As a brand owner, you need to promise your customers quality that endures. But you have to ask: will investing in those premium components actually deliver that longevity?

Absolutely. Premium brushes are specifically designed to last longer because every single component is chosen for durability. High-grade fibers are processed to resist shedding. Securely crimped ferrules prevent the dreaded head wobble. And properly sealed, lacquered hardwood handles resist water damage from repeated washing.

The number one killer of makeup brushes is washing. It’s a necessary evil for hygiene, but it’s also where cheap brushes meet their end. I want to show you exactly why a well-made brush survives.

Built to Withstand Water

When you wash a cheaply made brush, water seeps into the gap between the handle and the ferrule. The wood swells and cracks the paint, and the water breaks down the low-grade glue holding the bristles. Soon, the head gets wobbly and bristles start to fall out. A premium brush prevents this. We use multiple layers of lacquer to completely seal the wooden handle. We use strong, waterproof epoxy to set the bristles. And the double-crimped ferrule creates a tight physical barrier against water.

Maintaining Shape and Performance Over Time

Longevity isn’t just about the brush staying in one piece. It’s also about performance. Quality fibers, whether natural or synthetic, are treated to have "memory," meaning they spring back to their original shape after washing and use. This ensures your customer gets a consistent, flawless application for years, not just for the first few weeks. I still have brushes from a set I made for myself over ten years ago. They perform as well today as they did then because we didn’t cut corners on the components or the craftsmanship3.

You should wash your makeup brushes with dish soap.False

While possible, harsh dish soaps can strip natural oils from natural hair bristles, making them brittle over time. It's better to use a gentle shampoo or a dedicated brush cleanser to preserve the integrity of the fibers.

A lacquered wood handle is more water-resistant than a simple painted handle.True

Lacquer creates a hard, non-porous seal that is highly resistant to water penetration. A simple layer of paint can easily chip or crack, allowing water to seep into the wood underneath, causing it to swell and damage the brush.

Conclusion

Understanding brush costs—from materials to craftsmanship—empowers you to build a better product. It allows you to manage your budget strategically and grow your brand with tools built to last.

References

-

Exploring premium materials reveals how they enhance brush performance and longevity, crucial for brand reputation. ↩

-

Understanding ferrule construction can help you appreciate the durability and performance of premium brushes. ↩

-

Craftsmanship is a key differentiator in brush quality, affecting performance and customer satisfaction. ↩